PFAS, or per- and polyfluoroalkyl substances, continue to attract much attention from policymakers, the media, activists, the public as well as many companies that are making individual decisions about their supply chains. Unfortunately, misrepresentations have made it difficult to have serious, science-based policy discussions, as everything from the total number of PFAS chemistries in commerce to how heavily studied they are has become distorted.

PFAS are a diverse universe of chemistries. All PFAS are not the same. Individual chemistries have their own unique properties and uses, as well as environmental and health profiles. In fact, PFAS includes solid, liquid and gaseous chemistries. Commercial PFAS‐based products have been used in a wide variety of industrial and consumer applications because they have unique performance properties of significant socioeconomic value.

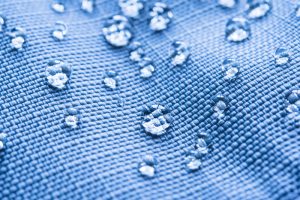

As the director of the Alliance for Telomer Chemistry Stewardship (ATCS), I work every day with member companies that produce a wide range of important C6 Fluorotelomer based products, including for many critical applications in the textile industry. Side chain fluorinated polymers are a polymeric subset of C6 Based Fluorotelomers and are used to treat textiles and nonwovens to impart water, soil, oil and stain resistance, and to provide a protective barrier against infiltration by contaminants. These side chain fluorinated polymer coatings are designed to be bound to the fibers when applied, providing unique performance benefits such as:

As the director of the Alliance for Telomer Chemistry Stewardship (ATCS), I work every day with member companies that produce a wide range of important C6 Fluorotelomer based products, including for many critical applications in the textile industry. Side chain fluorinated polymers are a polymeric subset of C6 Based Fluorotelomers and are used to treat textiles and nonwovens to impart water, soil, oil and stain resistance, and to provide a protective barrier against infiltration by contaminants. These side chain fluorinated polymer coatings are designed to be bound to the fibers when applied, providing unique performance benefits such as:

- Exceptional durability, leading to long lifetime of products with reduced resource intensity. For example, less frequent laundering, lower water/energy use to clean clothes, extended longevity of clothes so replaced less frequently and less sent to landfills.

- Protective barriers to safeguard against spread of infections and transmission of diseases in hospitals, health care and emergency response settings, including protection against microbial contaminants, such as viruses and bacteria, as well as other chemical and biological threats.

- Unique water- and oil-repellency (DWOR), including properties that help prevent hypothermia and resistance to extreme temperatures.

- Stain-resistance and soil release (repel-release).

- High heat and chemical resistance.

- Protection against contamination in clean room environments.

- UV resistance.

- Abrasion resistant finishes.

- Preserving the integrity of protective equipment, including life-saving bullet-proof ballistic fabrics.

- Ability to meet and comply with key performance and safety standards.

To be sure, side chain fluorinated polymers are a member of the broad class of PFAS chemistries. As such, these polymeric products have undergone rigorous testing for potential effects on both human health and the environment, including regulatory reviews by the U.S. Environmental Protection Agency (EPA). In addition, regulatory bodies in Europe, Canada and Asia have determined side chain fluorinated polymers meet relevant standards for the protection of human health and the environment.

Side chain fluorinated polymers have been thoroughly reviewed by regulators prior to introduction into commerce, are subject to ongoing oversight, and are supported by a robust body of rigorous scientific health and safety data. Side chain fluorinated polymers are not PFOS or PFOA, are not made with either chemical, and cannot be degraded to either of these chemicals. In fact, members of ATCS voluntarily worked with U.S. EPA to stop manufacturing and using those long-chain chemistries in the United States and globally through their PFOA Stewardship Program over a decade ago.

ATCS and our members support strong, science-based regulations that are protective of human health and the environment. We believe decisions by regulators as well as businesses about what products to use should be science based and data driven. Broad brush, one-size-fits-all regulatory approaches to PFAS could jeopardize many important products consumers and businesses rely on without having a meaningful impact on public health or our environment.

In fact, for many applications of side chain fluorinated polymers, no suitable alternatives exist or have been identified that can match their performance benefits. This performance is critical for textile applications such as Personal Protective Equipment (PPE) for healthcare workers, where C6 side chain fluorinated polymers provide the chemical barrier properties necessary to protect healthcare personnel against contact with microbiological contaminants, including blood-borne pathogens.

C6 side chain fluorinated polymers are also used in woven and nonwoven medical textiles/apparel, PPE for fire fighters and first aid responders, other rescue equipment such as safety vests, military, police and civil security equipment, outdoor apparel for extreme conditions and environments and many more.

C6 side chain fluorinated polymers are also used in woven and nonwoven medical textiles/apparel, PPE for fire fighters and first aid responders, other rescue equipment such as safety vests, military, police and civil security equipment, outdoor apparel for extreme conditions and environments and many more.

As producers and users of C6 side chain fluorinated polymer-based products, we understand the performance demands the textile industry must meet. Our industries can work together to help each other thrive and create products that enhance the quality of life for people around the world. We need your help to educate policymakers and the public about the benefits and safety of C6 fluorotelomers, and invite you to reach out so we can work together.

Editor’s Note: Shawn Swearingen is director of the Alliance for Telomer Chemistry Stewardship (ATCS)

November 2021