Hurricane Floyd Reduces Utility Output; Factory Output Down After

August Rise

Industrial production declined 0.3 percent in September, as Hurricane Floyd reduced utility

output and held back motor vehicle production and other goods. But even after adjusting for the

hurricane, the industrial output gain would have been small compared to increases of 0.4 percent in

August and 0.6 percent in July.

Factory output was down 0.2 percent after rising 0.5 percent in August. In the third quarter,

industrial output grew 3.7 percent at an annual rate, nearly matching the second quarter pace. The

operating rate of industrial capacity eased to 80.3 percent in September from 80.7 percent in

August.

The U.S. trade deficit of goods and services narrowed in August to $24.10 billion from $24.89

billion in July. Exports shot up 3.7 percent to $82.03 billion, up for the third month in a row,

while imports advanced 2.0 percent to $106.12 billion.

Business sales surged 1.3 percent in August, as durable goods sales jumped 1.5 percent on top

of a 1.0-percent rise in July. Non-durable goods shipments grew 1.1 percent. Business inventories

rose 0.3 percent. As a result, the August inventory-to-sales ratio dipped to 1.32 from 1.34 in

July.

Financial Markets Are Uneasy With The Federal Reserve Leaning Toward

Further Tightening

The evidence from latest set of economic reports is that the American economy, after two

interest rate hikes, is beginning to slow down. While the latest inflation readings appear to be

excessive there is no broad-based increase in prices. Nevertheless, with the Federal Reserve

leaning toward further tightening, financial markets are uneasy.

While economic activity and hiring was disrupted by Hurricane Floyd in the East Coast, the

loss of 8,000 nonfarm payrolls in September and the creation of only 103,000 jobs in August is a

clear indication of a slowing economy.

It is estimated that without the hurricane, nonfarm employment would have risen by 50,000

jobs in September. This is a major pullback from the dizzying pace of 654,000 jobs added in June

and July. Factory jobs continued to decline in September, falling by 21,000 jobs and bringing the

loss to 532,000 in the last year and a half period. The September jobless rate at 4.2 percent was

unchanged from August.

The Producer Price Index for finished goods shot up 1.1 percent in September, the largest

gain in nine years. Excluding energy, food, tobacco and automobiles, the price index was up just

one-tenth of a percent, hardly a sign of widespread price acceleration.

Consumer prices rose 0.4 percent in August. Energy costs accounted for 1/4 of the rise. The

core inflation was 0.3 percent after rising just 0.1 percent in August.

Textile Payrolls Fall After August Increase; Output Remains Slightly

Below Last Year’s Numbers

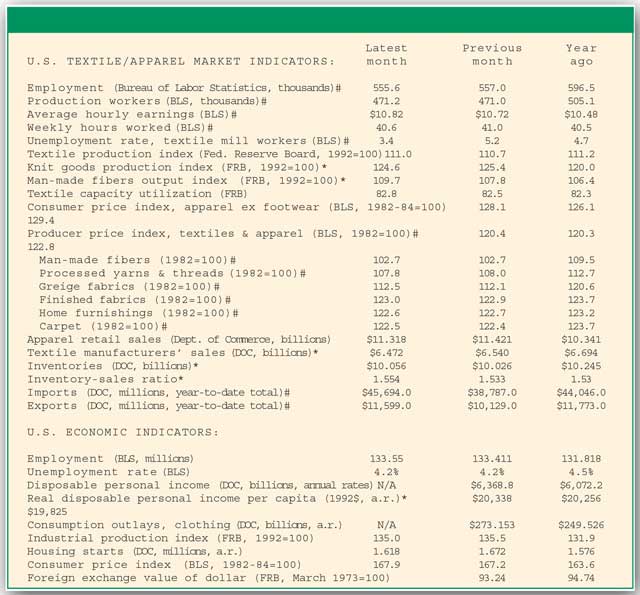

The textile industry’s payrolls fell 0.3 percent in September after edging up 0.1 percent in

August. The volatile jobless rate for textile mill workers dropped to 3.4 percent from 5.2 percent

in August.

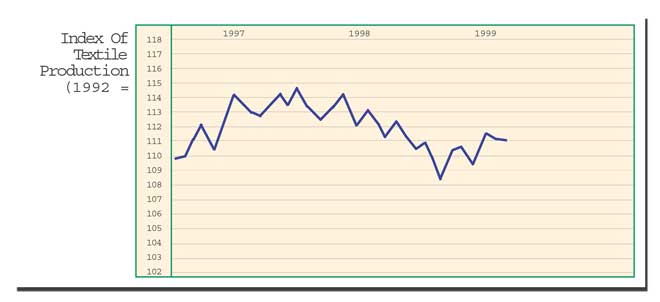

Textile output rose 0.3 percent in September. Despite strong U.S. economic activity textile

output remained slightly below the year ago level. The utilization rate for textiles improved to

82.8 percent of capacity from 82.5 percent in August. Shipments by textile producers declined 1.0

percent, giving back most of the 1.5-percent gain in July. Inventories increased 0.3 percent. The

August inventory-to-sales ratio rose to 1.55 from 1.53.

U.S. retail sales rose just 0.1 percent in September after surging 1.5 percent in August, the

largest gain in six months. Excluding autos, retail sales were strong, rising 0.6 percent. At

apparel and accessory stores, sales fell 0.9 percent. For the third quarter, total retail sales

were up by a startling 10.5 percent from a year ago.

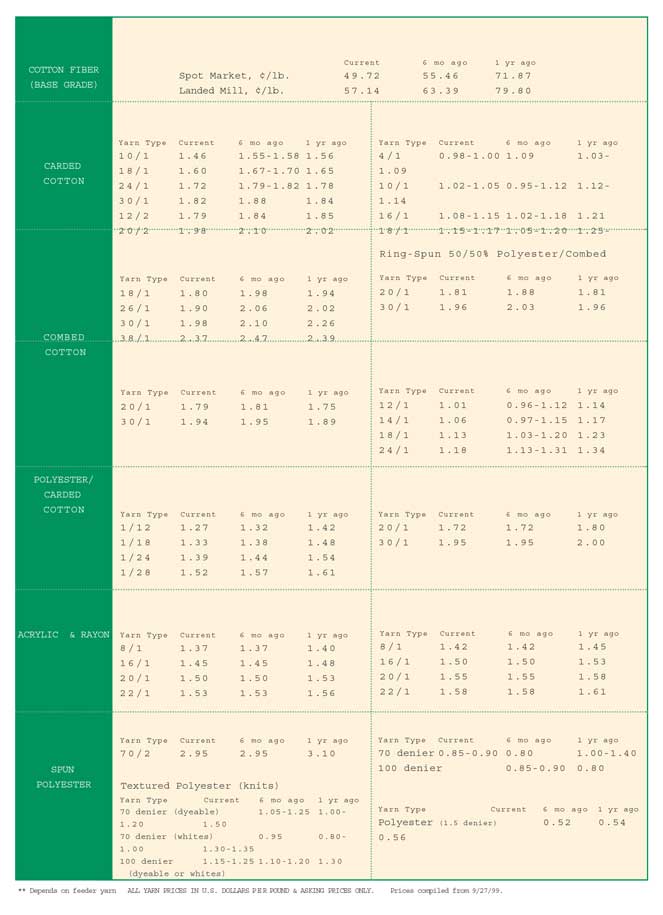

Producer prices of textiles and apparel edged up 0.1 percent in September, reversing declines

for five straight months.

Prices moved up 0.4 percent for gray fabrics and rose 0.1 percent for finished fabrics and

carpets. Prices declined 0.2 percent for processed yarns and threads.

November 1999