NEW DELHI — August 12, 2024 — Lindström India, a 100 percent subsidiary of the Finnish Lindström Oy, a global textile rental company offering workwear and cleanroom services in India, has announced the key highlights from its comprehensive Sustainability Report 2023. This detailed report outlines innovative strategies and practices that significantly reduce environmental impact while promoting circular economy principles in textile production and management.

NEW DELHI — August 12, 2024 — Lindström India, a 100 percent subsidiary of the Finnish Lindström Oy, a global textile rental company offering workwear and cleanroom services in India, has announced the key highlights from its comprehensive Sustainability Report 2023. This detailed report outlines innovative strategies and practices that significantly reduce environmental impact while promoting circular economy principles in textile production and management.

The report addresses critical environmental challenges and proposes innovative solutions to reduce the ecological footprint of textile manufacturing. Key highlights include optimizing water and energy use, minimizing waste through recycling and reuse, sourcing raw materials responsibly, and introducing cutting-edge technologies to support sustainable practices.

The report addresses critical environmental challenges and proposes innovative solutions to reduce the ecological footprint of textile manufacturing. Key highlights include optimizing water and energy use, minimizing waste through recycling and reuse, sourcing raw materials responsibly, and introducing cutting-edge technologies to support sustainable practices.

Key Highlights of the Report:

- Circular Economy in Action: Lindström India has successfully avoided millions of kilograms of unnecessary textile production through its robust repair and reuse programs. Demonstrating a tangible commitment to sustainability, Lindström at the Group level repaired 4.5 million pieces of workwear and 4.8 million pieces of textiles.

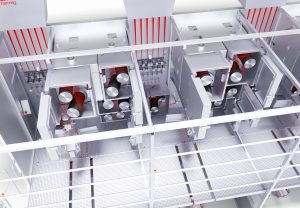

- On-Demand Production: The report showcases Lindström’s unique Prodem facilities, located in Navi Mumbai, which serve the whole country. In 2023, these facilities produced 237,086 pieces on demand. This customer-driven textile manufacturing practice minimizes overproduction, reduces waste, and improves cost efficiency.

- Resource Conservation: Lindström has optimized water and energy use in its laundries, as well as customer delivery routes, significantly reducing its environmental footprint. The company recycles water and utilises heat from wastewater in its washing processes.

- End-of-Life Solutions: The report details Lindström’s efforts in recycling end-of-life textiles into new products or raw materials, further closing the loop in textile production. In India, 100 percent of textile waste is recycled, showcasing the country’s commitment to sustainability.

- Impressive Statistics:

- 44 percent reduction in emissions achieved by doubling the wear time of garments.

- 2.2 kg CO2 avoided per person annually by using reusable garments.

- 9 months longer lifespan of textiles equals 20-30 percent smaller environmental impact.

- 67 percent fewer garments needed when using reusable options compared to non-reusable, customized garments.

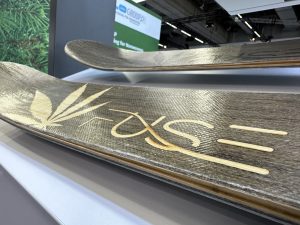

- Future Goals: While the group has set an ambitious target of including 30% recycled or bio-based fibers in new products by 2025, it is important to note that this target is mostly achieved through recycled fibers in mats and cotton towel rolls. Lindström India is aligned with these sustainability goals and is exploring ways to incorporate similar targets in its operations.

“This report represents a significant milestone in our ongoing commitment to sustainability in the textile industry. Our report not only underscores the urgency of addressing environmental issues but also provides actionable steps that can be taken by industry stakeholders to drive meaningful change,” said Jayant Roy, managing director of Lindström India. “By sharing our findings and strategies, we hope to inspire and lead the way towards a more sustainable future for textiles in India and beyond.”

Lindström’s report is part of its ongoing commitment to sustainability and corporate social responsibility. By sharing these findings, the company aims to foster collaboration and drive industry-wide adoption of sustainable practices. The full report, which includes detailed insights on choosing durable and repairable textiles, promoting reusability, and minimising stocks and inventories, is now available at https://lindstromgroup.com/sustainability-report/

Posted: August 12, 2024

Source: Lindström India, a 100 percent subsidiary of Lindström Group