bluesign is celebrating 25 years of helping the entire textile and apparel value chain deliver measurable impacts that matters to industry, people and the environment.

TW Special Report

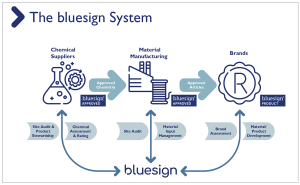

Switzerland-based bluesign technologies recently celebrated its 25th anniversary. Established in 2000 to offer sustainable chemical and environmental management solutions for the textile and fashion industry, bluesign developed a science-based input stream management system with the aim of eliminating harmful substances at the source. The system also helps ensure safer working conditions, reduces environmental impacts and provides safer products for consumers.

Today, bluesign counts more than 900 global system partners who work towards benchmarks for responsible production using bluesign’s criteria for chemical use, environmental performance and resource efficiency, while delivering measurable reductions in environmental impact.

“We are the only service provider in the textile sector offering a comprehensive eco-system approach that connects chemical management, manufacturing process optimization, and sustainable product stewardship,” said Barbara Oswald, chief commercial officer, bluesign.“Our work goes beyond certification and compliance. We deliver measurable improvement solutions and ongoing support to help our partners make sustainability an integral part of their business.”

“bluesign was born out of a bold idea, that sustainability could be embedded into the DNA of product creation,” said Daniel Rüfenacht, CEO of bluesign technologies.“Twenty-five years later, we’re proud to be a beacon of trust, innovation, and responsibility, and to partner with industry leaders worldwide in building a more sustain-able future together.”

Textile World recently had the opportunity to speak with Oswald as well as Esther Paez, bluesign’s Sustainability product manager, about the company and what lies ahead having achieved this milestone anniversary.

TW: How has bluesign’s mission evolved since the organization was founded 25 years ago, and what role do you see bluesign playing in the next decade as new regulations such as the EU Green Deal and Digital Product Passport take shape?

Barbara Oswald: Over the past 25 years, bluesign has evolved from an industry pioneer focused on safer inputs to a trusted partner driving sustainability transformation across the textile value chain. As regulatory expectations increase, our mission remains the same — to help industry produce the lowest possible impact on the environment and people, backed by primary verified data, transparency and practical solutions. Our system is geared for digital traceability and verified information that initiatives like the EU Green Deal and Digital Product Passport will require. In that sense, bluesign enables companies not only to comply, but to lead.

TW: There are other sustainability frameworks including ZDHC, OEKO-TEX, and GOTS. How does bluesign position itself among these organizations?

Esther Paez: We welcome the work of other frameworks that contribute to the industry’s sustainability goals. What makes bluesign unique is our integrated, end-to-end approach, geared towards sustainability improvement. We work across the entire value chain, connecting chemical suppliers, manufacturers, and brands through a single verified system. bluesign functions as a service partner, combining data-driven insight, on-site verification and continuous improvement support.

TW: How does bluesign ensure alignment and accountability among a wide range of mills, suppliers, and brands in the global System Partner network?

Paez: Alignment comes from a shared framework built on trust, transparency, and measurable performance. All bluesign System Partners are part of the same ecosystem, connected through common principles, verifiable criteria and a commitment to continuous improvement.

Each partner’s performance is verified on-site and supported through data analysis. But our approach goes beyond verification: Our experts work closely with partners to interpret results, identify improvement areas and implement solutions. This continuous engagement fosters accountability, builds capability, and strengthens collaboration across the entire network.

TW: What are some of the greatest challenges you see today in managing impact, and how does bluesign help manufacturers and brands address them?

Oswald: Today’s biggest challenge is navigating the complexity of multiple sustainability expectations — balancing impact reduction, costs, due diligence, reporting or compliance across many dimensions (ESG). Many companies struggle to connect these dots across their supply chain and geographies. bluesign helps by providing verified primary data, technical insight, and tailored improvement pathways that make sustainable transformation manageable. Through our collaborative model, we help partners move from reactive compliance to proactive impact reduction.

TW: How does bluesign measure and verify envi-ronmental improvements at partner facilities?

Paez: Our partner assessments go beyond certification to our standards, they are designed to drive measurable improvement. We measure resource efficiency, chemical performance, and emissions to air and water. Following each assessment, we share results and tailored improvement plans with partners, supporting them in setting clear targets and taking practical action. The verified data that results from this process provides a transparent and credible foundation for measuring progress and demonstrating real impact.

TW: How does bluesign maintain credibility in a world where greenwashing and self-reported data are common?

Oswald: Credibility comes from verification and science, not promises. bluesign enables its partners and brands to provide evidence-based sustainability data, helping them communicate honestly and avoid greenwashing. Our ongoing assessments and action plans are based on data review, technical validation and independent on-site evaluation. This gives both brands and consumers’ confidence that bluesign stands for proven, trustworthy performance.

TW: Are there any new innovations in pro-cessing or monitoring that excite you as potential breakthroughs in cleaner textile production?

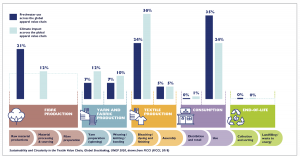

Paez: Innovation today is happening where chemistry, process efficiency and circularity meet. We’re particularly encouraged by advances in cleaner dyeing technologies, chemical recycling of polyester, and closed-loop systems that reduce waste and extend material life. bluesign’s solutions are flexible to accommodate these welcomed new developments — working with chemical suppliers, manufacturers, and recyclers to ensure that new processes meet our safety and sustainability requirements from the start. These innovations show that true sustainability is not about compromise — it’s about smarter chemistry, efficient production and a system that keeps resources in use.

TW: Certification can be complex and expensive, especially for smaller companies or those in developing regions. How does bluesign work with companies to make its services accessible?

Paez: We recognize that every partner has different starting points and capabilities. bluesign offers scalable implementation pathways, allowing each company to progress step-by-step while receiving hands-on guidance from our experts. Our role is to support, not to police. By offering practical tools, regional engagement, and capacity building, we help companies of all sizes participate in responsible production.

TW: Tell readers about the bluesign Academy.

Oswald: The bluesign Academy has long been recognized as our knowledge hub for sharing expertise and training across the industry. As we continue to evolve, this work is becoming more closely integrated within bluesign itself, reflecting how deeply knowledge and expertise are embedded in everything we do. Going forward, we may call it something different, but its purpose remains the same — to equip our partners and the broader industry with the under-standing, tools and insights needed to drive measurable improvement and responsible production. At its core, it’s still about the people and the expertise behind bluesign — helping our partners turn knowledge into lasting progress.

TW: Looking ahead, do you see a future where “clean production” is the default and not the exception? What will it take to tip the scales closer to a safer, cleaner textile production environment?

Oswald: That is exactly the future we are building toward. The shift will depend on these things:

- Collaboration — a shared responsibility across the entire value chain;

- Verification — so progress can be measured and trusted;

- Continuous improvement — supported by knowledge, data and partnership;

- Innovation and scalabilty — to ensure solutions can grow and deliver impact at every level of the industry; and

- Consumer awareness —empowering people to understand, trust, and choose responsibly produced textiles.

When these elements come together, responsible production becomes not an aspiration, but the industry standard.

TW: How is bluesign thinking about the role of consumers in driving sustainability?

Oswald: Looking forward, we are focused on building awareness with end consumers. Ultimately, the demand for sustainable products comes from those who buy them. By evolving our certifications, communication, and transparency, we aim to make it easier for consumers to understand, trust, and choose responsibly produced textiles.

TW: Please give a quick synopsis of your company’s value proposition. What should readers expect from bluesign in the future?

Oswald: bluesign is the only service provider in the textile industry offering a comprehensive eco-system approach, from chemicals to end products, built around delivering improvement solutions and ongoing support. We bring together science, data, and collaboration to help the industry reduce adverse impact and operate responsibly. What truly sets us apart is the long-term trust and collaboration we’ve built with our System Partners over more than two decades. These relation-ships allow us to continuously refine our system and deliver solutions that are both practical and proven. Looking ahead, we’ll continue expanding our system’s digital capabilities and supporting our partners through data-driven insights, collaboration, and innovation, always focused on measurable, real-world results.

TW: Why do you do what you do? What motivates you?

Oswald: Our motivation comes from the belief that sustainability should be achievable for everyone in the textile industry. We are driven by the progress we see when our partners reduce impact, improve operations, and lead the way toward responsible production. For us, it’s about partnership and empowerment, helping the entire value chain deliver measurable impact that matters to industry, people and the environment.

2025 Quarterly Issue IV