Stork Prints BV, the Netherlands, now offers NovaScreen® 195-19% — a combination of the open-area

NovaScreen 165 (mesh) screen and the high-resolution NovaScreen 195 (mesh) screen — for the textile

printing market. For printers that require voluminous paste supply, the hybrid screen offers a

high-resolution option with improved paste flow and printability.

Stork reports primary benefits of the new screen include: high screen volume and high

printing resolution; improved surface printing; and benefits in geometric printing.

A unique electroforming process allows Stork to control nickel growth during screen

production and push the ratio among hole size, mesh count and thickness of the screen beyond

conventional boundaries. By keeping the nickel growth mostly toward the top of the screen, the dam

shape stays thin and streamlined.

Stork reports that a smaller, more streamlined dam shape increases the chance of paste

flowing beneath the dam with lower squeegee pressure, thus creating a more even spread of paste on

the textile substrate. This even paste flow makes the screen suitable for pigment printing and

penetrative printing. In addition, the look and straightness of geometric and engraved prints is

improved, and improved rasterizations with dot definition generate quality halftone impressions.

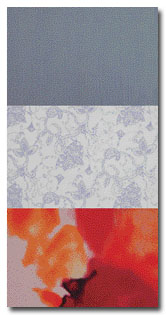

Stork Prints’ NovaScreen® for textile printing offers improved geometrical (top), fine-line

(middle) and halftone (bottom) printing.

May/June 2013