The TC 19i card from Germany-based Trützschler offers high production and more constant quality with less waste compared to latest high-performance card from a competitor, reports Turkey-based yarn manufacturer Iskur. This is the final evaluation after several months of intensive head-to-head testing.

“We facilitated the comparison of TC 19i with the competitor card at our premises because we wanted to make an informed decision for our next project” said Hakan Karagöl, general manager, Iskur Group. The aim was to achieve the maximum possible production with best possible quality and operating costs. On the basis of a cost-comparison and quality analysis from yarn to fabric, Iskur is now in favor of Trützschler regarding the spinning preparation line.

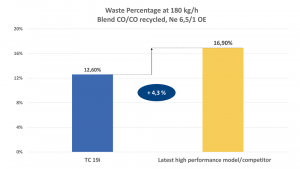

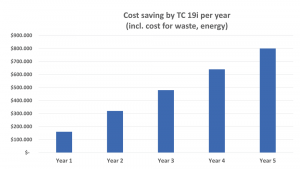

After months of comparative testing during which TC 19i showed better performance and quality, while the competitor card had to be continuously overhauled and reconfigured, the final trials took place beginning of 2022. In the first trial both cards ran at 180 kilograms per hour (kg/h) in the production of a rotor yarn Ne 6.5 made of a cotton and cotton recycle blend. Both competitors achieved comparable quality (IPI) now, and the final fabrics both matched the customer’s expectation. However, TC 19i showed significantly less unnecessary fiber waste — more than 4 percent. The cost savings of operating TC 19i compared to the competitor amount to $160,000 per year, which include other aspects like energy consumption and maintenance expenses.

After months of comparative testing during which TC 19i showed better performance and quality, while the competitor card had to be continuously overhauled and reconfigured, the final trials took place beginning of 2022. In the first trial both cards ran at 180 kilograms per hour (kg/h) in the production of a rotor yarn Ne 6.5 made of a cotton and cotton recycle blend. Both competitors achieved comparable quality (IPI) now, and the final fabrics both matched the customer’s expectation. However, TC 19i showed significantly less unnecessary fiber waste — more than 4 percent. The cost savings of operating TC 19i compared to the competitor amount to $160,000 per year, which include other aspects like energy consumption and maintenance expenses.

In the second trial, the production target was increased to 250 kg/h. After some adaptations the competitor card now ran at comparable waste levels like TC 19i. However, IPI results of TC 19i were about 30-percent lower, yarn breaks about 60-percent lower, and clearer cuts 45-percent lower. TC 19i produced about 850 kilograms more in the same time period. “We observed that IPI values and waste percentage of the competitor card varied more from day to day, while Trützschler TC 19i quality and waste values remained comparatively constant. The fabric from TC 19i fully met our expectation, both after the 180 kg/h and the 250 kg/h trial. In contrast, the fabric that stemmed from competitor card production at 250 kg/h did not match our reference fabric anymore,” concluded the customer.

The intelligence of TC 19i — including the permanent, automatic optimization of the carding gap during production and the automatic recognition and setting of waste removal — leads to better results. The TC 19i provides high production with best possible quality and waste removal, as well as lower energy consumption in direct comparison.

The intelligence of TC 19i — including the permanent, automatic optimization of the carding gap during production and the automatic recognition and setting of waste removal — leads to better results. The TC 19i provides high production with best possible quality and waste removal, as well as lower energy consumption in direct comparison.

April 21, 2022