ZWEVEGEM, Belgium – Bekaert is continuously investing in new technologies that advance our

customers’ competitive edge. One of our latest accomplishments that benefits the textile industry

is the production of the SiroLock® doffer and worker wire for non-woven and long staple roller

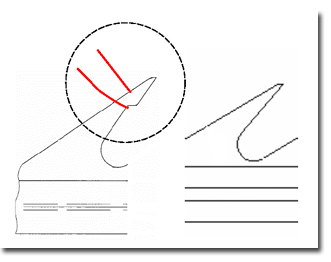

cards. This highly efficient card wire is provided with a unique step (figure 1) which brings fiber

control to a whole new level, improving both web quality and the productivity of the cards.

Figure 1: SiroLock® controls the fibers at the step at the front of the wire which enables

it to take more fibers than conventional wires.

A step up in fiber control

The concept of the SiroLock® wire was developed by Ken Atkinson of The Commonwealth

Scientific and Industrial Research Organisation of Australia (CSIRO) and executed by the technical

team of Bekaert .

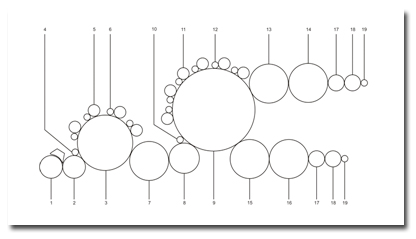

SiroLock® performs best on workers and doffers of the breast section and of the main

cylinder. (As an example see roller 7, 5, 11, 13 and 15 of the card lay-out shown in figure 2). The

wire takes up to 50% more fibers compared to any conventional card wire (figure 3). As a results

there is less recycling of fibers on the cylinder, which leads to higher card productivity. Less

recycling causes less loading of the cylinder wire, meaning less cleaning time required of the

cylinder roller. In addition the improved fiber control leads to the reduction of fly, which

reduces the cost of the raw materials and leads to a more regular web. As SiroLock® wire also

creates higher carding spaces, it allows for wider settings and better blending which also

contributes to a higher web quality.

Figure 2: Example of a modern nonwoven card (Fiber flow from left to right hand side; 1:

feed roller, 2: lickerin, 3: breast roller, 4 & 10: fly stripper, 5: breast workers, 6: breast

strippers, 7: breast or intermediate doffer, 8: transfer roller, 9: main cylinder, 11: main

workers, 12: main strippers, 13 & 15: random rollers, 14 & 16: main doffers, 17 & 18:

condenser rollers, 19: take-off roller)

Figure 3: Sirolock® card wire (figure at the left) and conventional wire (figure at the

right)

Flexible processing of various fibers and blends

The first industrial results with SiroLock® in the non-woven industry have already shown very

positive improvements in both quality and productivity. This has also to do with the versatility of

the product: SiroLock® can be used to process a wide range of fibers and even special fibers and

blends like hollow fibers, siliconized fibers, aramid fibers (para- or meta-aramid), high

percentage of melt fibers and a broad range of fiber densities (dtex). One customer even uses

SiroLock® to card goat hairs in combination with 150 dtex uncrimped polypropylene. No other wire

was capable of handling coarse and uncrimped fibers, but SiroLock® managed the job perfectly.

SiroLock® in practice – crosslapping and direct way applications

• The benefits of SiroLock® in crosslapping applications – a few examples:

Sioen-Nordifa

Belgium

Application: technical needle felts, including filtration fabrics

Sioen-Nordifa is processing a wide range of fibers (polyester, viscose, acrylics, low melt

fibers…) and fiber densities (4 – 15 dtex). Sioen-Nordifa uses SiroLock® on workers and doffers

on a Thibeau Excelle card

Result:

• Improved web regularity and web appearance

• Even colors

• Improved web tensile strength

• Increased production of 20 to 40% (depending on fiber blends and final

product)

• Elimination of dust formation in the card thanks to the improved fiber

control and reduced fiber recycling on the cylinder.

Domo

Belgium

Application: needled carpets

Domo uses Thibeau and Spinnbau cards to process 3.3 – 15 dtex fibers. SiroLock® is mounted on

the workers and doffers of the breaker and the finisher cards.

Result:

• Increased production speeds of 20%

• Less fibers load on the card ⇨ Less card cleaning⇨ Reduced downtime

Elco Solutions Pty Ltd

Australia

Application: Needle punching

Elco Solutions is a producer of geotextiles and geosynthetic products for a wide range of

applications like highways, railroads, coastal protection, waste containment, mining and sports

field applications. While looking for a way to upgrade both productivity and the quality of their

products, Elco Solutions decided to mount V20 SiroLock® wire on their doffers. These were their

findings:

“Soon after installing SiroLock® we noticed that our productivity rates went up

dramati¬cally. Furthermore the quality of our products exceeded all expectations. Calculations

showed that at this rate of production the investment pay back was just three months. The

performance of SiroLock® is exceptional and we will continue to use this technology.” – Mr. Brendan

Swifte, Chairman of Elco Solutions Pty Ltd

• The benefits of SiroLock® in direct way applications – a testimonial:

Textor Textile Technologies

Australia

Application: Spunlace production for wet wipes

“Initially we used the SiroLock® wire on the workers and over time this permitted a 30%

increase in capacity as well as an improvement in web picture. We have just installed a finer

version of the SiroLock® wire on a new card and the fiber pick up was so great that the stripper

wires now have to be upgraded. In our mill, we believe that SiroLock® will be a valuable tool to

increase productivity and web quality over the coming years. It is not a simple solution as there

is considerable card tuning necessary. It forces you to understand the science of carding. We are

producing web weights and qualities that are world class and at rates which increase each year.

Without SiroLock® we would not be in this position”. – Mr. Phillip Butler Director of Textor

Textile Technologies

About Bekaert

Bekaert (www.bekaert.com) is a global technological leader in its two

core competences: advanced metal transformation and advanced materials and coatings, and a market

leader in drawn wire products and applications. Bekaert (Euronext Brussels: BEKB) is a global

company with headquarters in Belgium, employing 23 000 people worldwide. Serving customers in 120

countries, Bekaert pursues sustainable profitable growth in all its activities and generates annual

combined sales of € 3.3 billion.

Bekaert: the reliable partner for your card wire needs

Bekaert reinforces its status of independent and recognized leader in the card clothing

business through partnerships with textile machine builders and customers world wide. Thanks to our

technical know-how, our in-house developed machinery, our careful wire rod selection and our

thorough understanding of the drawing, shaping, punching and heat treatment processes we can create

a card wire that meets your expectations.

Posted on August 3, 2010

©2010 NV Bekaert SA