Established by the Department of Energy in 2015, the Institute for Advanced Composites Manufacturing Innovation® (IACMI) has emerged as a leader in advanced composites and workforce solutions, bolstering American manufacturing and national defense.

TW Special Report

The Institute for Advanced Composites Manufacturing Innovation® (IACMI), also known as IACMI–The Composites Institute®, recently celebrated a decade of revitalizing American manufacturing and strengthening the nation’s defense industrial base. Established by the Department of Energy (DOE), IACMI was announced as the fifth of now 18 Manufacturing USA® institutes on January 9, 2015. The Advanced Functional Fabrics of America (AFFOA) is also a Manufacturing USA institute.

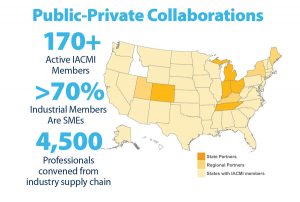

The institute comprises more than 170 members — including those from industry, universities, national laboratories and government agencies — that work together to accelerate the development and adoption of advanced composites and innovative manufacturing technologies. Its collaborative work through public-private partnerships drives domestic production capacity, strengthens U.S. manufacturing competitiveness and elevates domestic job creation.

IACMI is managed by the Collaborative Composites Solutions Corp. (CCS), a not-for-profit organization established by the University of Tennessee Research Foundation. IACMI is supported by the U.S. Department of Energy’s Advanced Materials and Manufacturing Technologies Office, and the U.S. Department of Defense (DoD) Industrial Base and Sustainment (IBAS) Program from the Innovation and Capability and Modernization (ICAM) office, as well as key state and industry partners.

IACMI Impact

For 10 years, IACMI has played a pivotal role in America’s reindustrialization, aiming to secure its position as a global leader in manufacturing innovation and workforce development. Reshoring initiatives have been key to bolstering U.S. economic and national security. Through multiple national workforce programs sponsored by DOE and the DoD, IACMI has been inspiring, educating, and training a skilled workforce to help address the projected 4.6 million open manufacturing jobs in the coming decade.

IACMI’s impact for economic growth has been clear in four primary ways:

- Public-Private Collaborations — Convening more than 170 members and 4,500 professionals from industry, academia, and federal labs to tackle the composites industry’s toughest challenges in automotive, aerospace, wind, infrastructure and the circular economy.

- Technical Innovation — Connecting more than 90 of its members to conduct 60-plus industry-led R&D projects that helped commercialize dozens of products; advance the Technology Readiness Level (TRL) of numerous technologies; and create hundreds of design, engineering, and manufacturing jobs.

- Workforce Development —Catalyzing IACMI, Americas Cutting Edge (ACE), and Metallurgical Engineering Trades Apprenticeships & Learning (METAL) programs to enable:

- More than 100 internships with industry collaboration resulting in 100-percent placement in industry jobs or higher education;

- 18,300-plus STEM outreach engagements;

- More than 12,400 trained online across 50 states in CNC machining;

- 5,100-plus trained in-person in composites, CNC, metrology, and metallurgy; and

- 40 machine tool training centers in 14 states.

- Leveraging Resources — Providing open access to more than $400 million in scale up facilities across eight states has led to an additional $220 million-plus for companies, universities, national labs and workforce initiatives.

“For 10 years, IACMI has harnessed the power of public-private partner-ships to improve products, processes, and people’s lives through composites innovation and workforce solutions that secure America as a global leader in advanced manufacturing,” said Chad Duty, IACMI’s CEO. “With steadfast investment and support from industry and government partners, notably DOE and DoD, IACMI has empowered domestic manufacturers to accelerate design and commercialization, fostering a more reliable, secure, and competitive U.S. economy.”

Shared Infrastructure, Investments

Since 2015, IACMI, the DOE, and state economic development organizations have invested in a shared infrastructure that collectively delivers a breadth and scale of open-access advanced composites manufacturing R&D capabilities that stand unmatched in the U.S. These facility and infrastructure investments have been led by IACMI’s core innovation partners in Colorado, Indiana, Michigan, Ohio and Tennessee. Today, these capabilities uniquely position IACMI to build on past achievements, de-risk future research, and accelerate onshoring efforts in the United States.

Examples of state-of-the-art scale-up facilities include:

- Manufacturing Demonstration Facility (MDF) at Oak Ridge National Laboratory (ORNL), Oak Ridge, Tenn.;

- Carbon Fiber Technology Facility (CFTF) at ORNL;

- Fibers and Composites Manufacturing Facility (FCMF) at University of Tennessee, Knoxville, Tenn.;

- Laboratory for Systems Integrity and Reliability (LASIR) at Vanderbilt University, Nashville, Tenn;

- The Composites Laboratory at the University of Dayton Research Institute, Dayton, Ohio;

- The Composites Manufacturing & Simulation Center (CMSC) at Purdue University, West Lafayette, Ind.;

- The IACMI Scale-Up Research Facility (SuRF) in Detroit; and

- The Composites Manufacturing Education and Technology Facility (CoMET) at National Renewable Energy Laboratory (NREL), Applewood, Colo.

IACMI has leveraged these facilities to undertake transformational R&D, in nation-critical industries including energy, transportation, aerospace, and infrastructure & construction. An IACMI-sponsored project team helped Volkswagen (VW) of America redesign and validate a composite liftgate for SUVs, reducing the weight by 35 percent and lowering its recurring cost by 9 percent compared with steel. Technological advances from this research are now being used across multiple VW platforms, including the new VW ID Buzz EV.

The scaling, manufacture and testing of novel thermoplastic wind turbine blades that are recyclable and lower in cost has also been demonstrated. Further research in automating finishing processes for wind blades aims to reshore wind manufacturing jobs. Simulation and modeling work to develop a virtual twin for additive manufacturing is revolutionizing the production of tooling.

Today, these capabilities uniquely position IACMI to build on past achievements, de-risk future research, and accelerate onshoring efforts in the United States. Duty predicts, “Over the next few years, IACMI and its partners will leverage their full-scale facilities and equipment and significantly expand programs. IACMI will continue to convene, connect, and catalyze the U.S. composites community by attracting startups and small enterprises while creating opportunities with large companies, national labs, and universities. Our ecosystem of innovation is ready to advance American manufacturing.”

To learn more about IACMI, visit IACMI.org.

2025 Quarterly Issue I