At first blush, the provocative headline — “4 Smart Textiles You’ve Yet to See” — in a recent issue

of Popular Science seems out of place. The article predicts what it deems are the textiles to watch

for in the near future — self-repairing fabric, water-soluble fabric, environmentally responsive

fabric that shifts shape or changes color in response to temperature, and “bio-leather” — all meant

to inspire fashion designers. Indeed, high fashion is grabbing its share of headlines these days.

As Textile World has previously reported, designers of fashion and products for wellbeing are

being inspired by new textile developments, and many designers are taking advantage of new textile

capabilities and applying them to new medical and other end-use applications. Although architecture

tends to follow trends rather than lead, it is starting to adopt some of the advanced developments

in textiles first used by fashion designers.

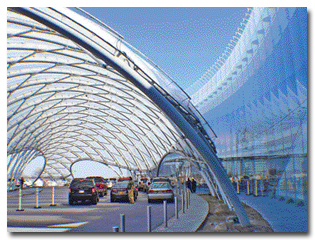

The Empire City Casino at Yonkers Raceway, designed by FTL Design Engineering Studio, is

sheltered by a single layer of ETFE. First developed as insulation for electronics

applications, ETFE has been adapted successfully to architecture, inspiring new forms. Photo

courtesy of FTL Design Engineering Studio

Technology Transfer — Historic Antecedents

Most new material innovations in architectural construction come from outside the industry.

For example, the mid-20th century development of the now-ubiquitous glass curtain wall was

influenced by the automobile industry’s perfection of neoprene window seals for windshields. This

new technology found its modernist ideal in Eero Saarinen’s design of the General Motors Technical

Center — built in Warren, Mich., in 1955 -where he applied neoprene to the center’s glazing façade

system.

More recently, the adaptation of ethylene tetrafluoroethylene (ETFE) — first used as an

insulator for electronics applications — to architectural use has opened many new possibilities for

building design and function, most notably seen in the 2008 Beijing Olympics water sports venue.

Today, architecture is no less beholden to new technologies. In truth, they have always been

the drivers of both new design and better construction as improvements in material performance and

construction methods are made in response to economic as well as environmental demands, such as

increased sustainability and energy efficiency standards. New textiles are playing a growing role

in innovative architecture and construction.

There are several research areas in which textile innovation is beginning to influence

architectural design, including medical, military and fashion textiles. Another major influence is

not so much a research area, but a social trend — the increasingly mobile nature of business,

culture and daily activity.

Medical Textiles

Many developments in the medical device market have parallel developments in the construction

and architecture design markets, such as textiles that are able to sense and react to environmental

conditions (See “Medical Textiles: How Smart Do They Have To Be?,” TW, November/December 2012).

Architects are finding practical use of fabric coatings that help to fight bacteria or reduce

pollutants in the air — such as titanium dioxide (TiO2) — by applying them in healthcare facility

and clinic designs in which these specialized textiles are used to provide enclosures or

partitions. Healthcare worker apparel can be treated with the same antibacterial/antipollution

finish. Ongoing research in this area will yield many new possibilities, and it is expected to be

the most fertile field of interest for architecture and construction.

Military Research

Following a trend that began 150 years ago during the American Civil War — which saw the

production of lightweight, portable fabric camp furniture and tents — military research into

materials and performance characteristics continues to drive innovation on the architectural front.

A short list of recent innovations includes flexible photovoltaics (PV), low-pressure fabric

airbeams, and non-radiant fabrics that render military tents or deployable structures invisible to

an infrared heat signature.

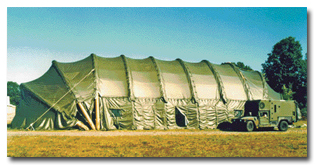

The architects and fabric structure experts at New York City-based FTL Design Engineering

Studio have worked closely with the U.S. Army Natick Soldier Research, Development and Engineering

(RD&E) Center, Natick, Mass., on lightweight fabric airbeam-supported structures designed for

use in the Middle East. These deployable structures also incorporate flexible PV panels that help

to generate electricity for lighting the interiors.

Research and collaboration between FTL Design Engineering Studio and the U.S. Army Natick

RD&E Center produced the innovative Large Area Night Maintenance Shelter deployable structure

supported by fabric airbeams and covered by laminated fabric. Photo courtesy of FTL Design

Engineering Studio

Fashion Drivers

New material developments regularly find a willing partner in couture, as the fashion media

are very adept at publicizing anything new, and designers are in constant need of fresh ideas. For

example, in recent years, fashionistas have embraced the use of “smart textiles,” including

textiles that can carry data as well as lumens — electrotextiles that display a message or colorful

pattern — or textiles that feature high-performance capabilities for combating specific biological

problems (See “French Technical Textiles Industry: Futurotextiles 3: Nexus Of Technology And Art,”

TextileWorld.com, March/April 2013).

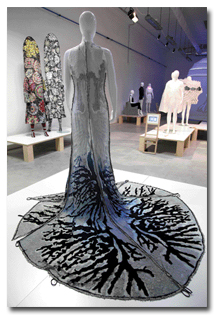

A coating of TiO2 on the fabric of the Herself Dress, created by British fashion designer

Helen Storey, works to break down pollution and freshen the air. Photo courtesy of Maxime

Dufour

Society On The Go

New mobility is driving the need for lighter-weight materials and the demand for more

data-metric information about the environments that people move through. New methods of collecting

and transmitting the data are coming online and will help both the designers of spaces as well as

the users of the spaces in ways that bring greater understanding. For example, the French company

Bodysens S.A.S. has developed a protective hood for firefighters with sensors in the lining that

measure heart rate and other vital signs of the user, and that allows hands-free communication via

digital radio transmission between user and colleagues. Another promising technology involves

chromographic textiles that change color in response to temperature changes. This textile

technology could very well be adapted to the design of medical facilities in which close monitoring

of the environment may be critical and a visual reference to fluctuations may assist doctors and

technicians with treatments.

Lighter, more mobile buildings will be necessary as rapidly shifting public gatherings and

dynamic groups like meetups, impromptu performances and such will require flexible, dynamic spaces.

Pop-up stores will be possible because of durable, lighter-weight materials that provide protection

and colorful, customized graphics.

Future Possibilities

Another area to watch would be composites. As with air and transportation applications,

composites are going to see increased importance in construction as designers seek greater

performance characteristics at lighter and lighter weights to reduce the building carbon footprint.

High performance and extreme light weight are, increasingly, qualities that can only be attained

with the use of textiles.

Editor’s note: Bruce N. Wright, AIA, is an architect/journalist living in Minneapolis.

September/October 2013