It’s no question that sustainability is a highly valued selling point. We hear — and probably use — related terms like “responsible sourcing,” “traceability,” “transparency,” and “product stewardship” daily. The terms sound good, but how can they be implemented to make a tangible impact?

Suppliers face significant pressure from brands and retailers to be transparent about these issues and the solutions they have in place. There are numerous other challenges within the complicated supply chain as well, from hazardous chemicals and fair labor standards to changing trends and customer requirements. How can you communicate with brands and retailers to fulfill these demands and secure business?

Where to start?

To avoid wasting precious time, money, and effort, ask yourself a few questions. As a supplier, how does your factory select chemicals? What programs are in place to control manufacturing processes, measure quality, protect your employees, and ensure compliance with environmental regulations? Can you prove your facility is safe and compliant? By answering, you can more readily prepare your company for fulfilling demands and securing itself as a sustainable, responsible organization, thus adding value for markets around the world.

You’re not alone.

For more than 70 years, Hohenstein, an independent testing and research institute, has been dedicated to improving the human-textile-environment interaction through standard and customized testing, certification, training, and product development programs.

In 1992, Hohenstein co-founded the OEKO-TEX® Association, which has since grown to 18 member institutes globally. OEKO-TEX leads the world in setting rigorous, scientifically-based standards to test and certify products and processes throughout the supply chain, from chemical products to manufacturing processes through consumer labeling.

The OEKO-TEX system enables suppliers and consumers to protect our planet by making responsible decisions.

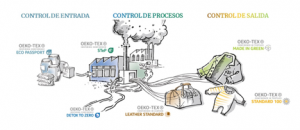

OEKO-TEX product labels help consumers and customers find products tested for harmful substances (STANDARD 100 and LEATHER STANDARD by OEKO-TEX) and manufactured in an environmentally friendly and socially responsible way (MADE IN GREEN by OEKO-TEX). Verified chemicals (ECO PASSPORT by OEKO-TEX) and manufacturing facilities (STeP by OEKO-TEX) ease sourcing decisions and sustainable manufacturing. The modular system ensures these systems work together for traceability, transparency, and cost reduction.

Output Control

Output Control

STANDARD 100 by OEKO-TEX tests for harmful substances on products and accessories throughout the supply chain. LEATHER STANDARD by OEKO-TEX is an adaptation of STANDARD 100 for issues specific to the leather industry. Both restricted substance lists (RSLs) are annually updated to incorporate health data and stay ahead of global laws.

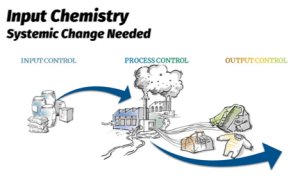

Input and Process Control – for cleaner, safer output

ECO PASSPORT by OEKO-TEX helps producers identify and purchase safer chemicals through RSL/MRSL screening, testing, and product stewardship site visit — optional, for ZDHC level 3 compliance.

STeP by OEKO-TEX certification considers all aspects of sustainable production and provides solutions for continuous improvement through assessment and auditing.

Traceability

The Made in Green label identifies products that are certified safe from harmful substances by STANDARD 100 by OEKO-TEX and were sustainably produced in STeP by OEKO-TEX certified factories. Each product ID gives customers a unique level of transparency by tracing the product’s supply chain.

Sustainable Sourcing

OEKO-TEX works with over 15,000 OEKO-TEX certified suppliers that own nearly 170,000 certificates throughout the supply chain. Access to these companies in the searchable, online OEKO-TEX Buying Guide is free.

Future

Future

Sustainability-focused demand for safe, responsibly produced products is growing and suppliers, brands, and retailers are partnering with Hohenstein to leverage the OEKO-TEX system in lieu of independent auditing and RSL/MRSL development. With the OEKO-TEX system, there’s no need to face the challenges of fulfilling sustainability demands alone.

Editor’s Note: With 1,000 worldwide employees, Hohenstein expertise covers topics such as comfort, compression, odor, fit & pattern, sustainability, UV protection, and safety. Hohenstein’s commitment to consistent quality means our local labs deliver dependable results -indistinguishable from the headquarters lab in Germany. Hohenstein is certified by the U.S. Consumer Products Safety Commission (CPSC ID #1058) as a third-party, independent laboratory for CPSIA compliance verification. Hohenstein.US/OEKO-TEX, USA@Hohenstein.com.

October 18, 2019