Tailored Industry relies on WHOLEGARMENT® technology from Shima Seiki for its consumption area-based, on-demand production system.

TW Special Report

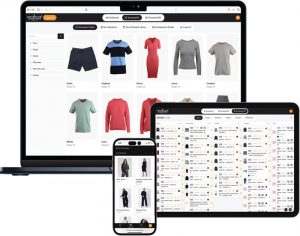

Support for small-lot production is becoming more commonplace in the apparel industry despite its difficulty breaking away from traditional mass production. Tailored Industry Inc., Brooklyn, N.Y., is taking small lot to the next level with its proprietary on-demand software platform, which enables zero minimum order quantity (MOQ) production for apparel brands in the United States.

“By pairing our on-demand production platform with Shima Seiki’s WHOLEGARMENT knitting machines, we eliminate overproduction, precisely match demand with supply and empower apparel brands with a competitive supply chain, noted Alex Tschopp, co-founder and CEO of Tailored Industry.

A Vicious Spiral Of Excess Inventory

In recent years, sales in the apparel industry have often been stagnant among brands, and surplus stock is generated despite heavy discounts to incentivize sales. The original goal of mass production was to reduce production costs, which led companies to shift production overseas in search for cheaper labor.

Since mass production facilities require large-scale capital investment, fixed costs are high. If these facilities don’t maintain high capacity utilization, production costs add up quickly. This dynamic is why factories set high MOQs to maintain overhead and labor costs. Unfortunately, this leads directly to overproduction, financial losses and environmental waste. More than 10 million tons of apparel go into landfills every year according to the U.S. Environmental Protection Agency.

Time Efficiency From Order To Delivery

Time Efficiency From Order To Delivery

Tailored Industry notes how these issues of overproduction, waste, and inventory management not only affect factories, but the industry as a whole.

“At Tailored Industry, we have designed our software platform and business model to combat the largest issue with the apparel supply chain – inventory,” Tschopp said. “Using our platform, brands don’t have to produce products ahead of time. Once a brand receives an order online — as few as one unit — they submit it to us through our software. We produce and drop ship the products directly to their end customers in three to six days. This model, which we call Manufacturing as a Service — software and manufacturing — connects demand with supply. The process reduces wastage in multiple areas, including raw materials, time, and energy. Ultimately, these savings lead to many advantages across the supply chain and create a powerful competitive advantage for apparel brands.”

What You Need When You Need It, On Demand

What You Need When You Need It, On Demand

“Conventionally, it takes well over six months to design, develop, and mass produce a knitwear collection,” Tschopp said. “This process requires brands to guess how much stock they need per style, color and size. However, forecasting demand accurately is impossible, almost by definition.”

The model of pairing WHOLEGARMENT knitting machines with Tailored Industry’s on-demand software has created a supply chain alternative for apparel brands, one that facilitates production after an order is placed. “WHOLEGARMENT knitting machines are a crucial part of what allows us to achieve this quick turnaround, while maintaining a luxury-grade quality,” Tschopp noted. “This shift to on-demand manufacturing is also known as consumer area-based production where goods are locally produced and locally distributed.”

Sustainable And More Efficient Production Methods

Sustainable And More Efficient Production Methods

One of the challenges facing the new consumer area-based production is the perception of a higher price, when compared to mass production pricing. On-demand production does result in higher production costs per item. However, apparel brands must evaluate the all-in cost of garments produced overseas and include the cost of shipping, importing duties, storage, liquidation discounts, and the disposing cost of unsold goods. The all-in costs associated with overseas production, combined with the elimination of excess inventory make on-demand manufacturing less expensive and more profitable than mass production. These factors make on-demand production the most sustainable form of production in the apparel industry.

November/December 2022