Weaving technology manufacturers are on the way to developing Industry 4.0-ready machines.

By Dr. Abdel-Fatah M. Seyam, Technical Editor

ITMA always means new technology. At the latest edition, developments were characterized by innovative technologies, digital formation of fabrics and garments, digital printing, addressing sustainability concerns, formation of innovative products — such as e-textiles, 3D, and sportswear — and software.

During ITMA, weaving stands were well attended by visitors. The major machine manufacturers demonstrated diversified machines for formation of woven products for apparel, home textiles, and technical textiles applications; and marketed their technologies as Industry 4.0 ready.

Warping, Sizing and Sample Weaving

To be competitive and meet the demand for new product diversity, rapid prototyping machines for sample production and evaluation prior production are necessary. Using production warping, sizing and weaving machines to produce small samples leads to significant loss of production and material waste.

CCI Tech Inc., Taiwan, specializes in sample warpers, sizing winders and sample weaving machines. The company showed its new Lutan.com sample warping machine with creel integrated into the movable warping ring, which offers space savings compared to the earlier Lutan v5.0 and v3.6 versions.

Lutan.com features a 2.6-meter working width, 15 to 500-meter warp length range, 14,400 meters per minute (m/min) warping speed, 24 creel capacity, 5-meter pattern drum circumference and 10 lease rods. The machine is capable of producing intricate color sequences for narrow-wide samples and medium run production. Lutan.com is equipped with built-in Lutronic and SE-edit software with a user-friendly interface for setting the color sequence, number and locations of leases and other warp specifications. Per the user input, the machine automatically forms the warp with desired specifications. Beaming events do require operator intervention to transfer the warp from the pattern drum to the warp beam.

CCI Tech also offer sizing winders, a machine that presents the simplest route for making sized yarn packages for sample warpers. The company recently introduced the 2-spindle sizing winder Taroko offered in 2-spindle and 4-spindle modular versions for a maximum of 4 modules or 16 spindles. Each spindle is individually controlled using a dedicated driving system, size box and heating zone, which allows the machine to run different yarns with different size formulas, size concentrations or size-wet-pickup. The machine may run up to 500 m/min sizing speed. The Taroko is equipped with industrial PC/Windows OS and internet access via WiFi/Ethernet for remote control and monitoring of each position.

During ITMA, CCI Tech also introduced two of its single rapier sample weaving machines — evergreen II and Kebalan. The evergreen II has the same features as the previous version evergreen I, but is more compact and much faster. It is available in weaving widths of 50 centimeters (cm) or 90 cm and can run at a weaving speed of up to 100 picks per min (ppm). The Kebalan, which is still in the prototype stage, offers a high weaving speed of 300 ppm — a record in sample weaving. The shedding motion uses 8 or 16 harnesses, featuring individual harness control using servomotors, weft break detection and optional warp stop motion. The machine is equipped with eight weft feeders to cope with the high-speed weaving.

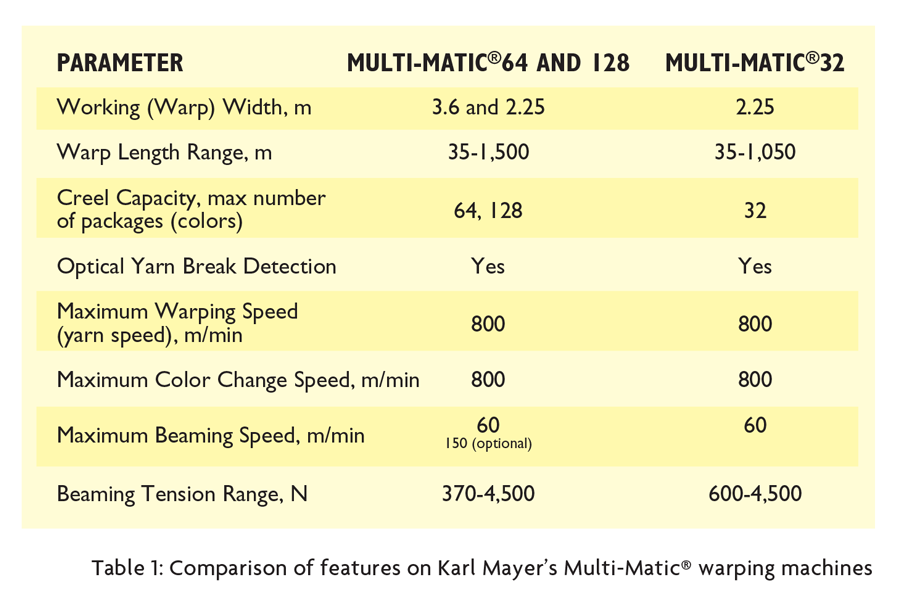

Germany-based Karl Mayer Textilmaschinenfabrik GmbH showed the sample warper Multi-Matic®32 at ITMA 2019. The 32 denotes the creel capacity, which permits the use of 32 different yarn colors. Three versions of the Multi-Matic — with creel capacity 32, 64, and 128 wound packages — are available providing flexibility in terms of creel capacity depending on the space and applications required by weavers. A comparison of the three Multi-Matic versions of is shown in Table 1. The machines are capable of producing warp lengths ranging from 35 to 1,050 meters for the 32 model, or 35 to 1,500 meters for the 64 and 128 versions. With such range of warp length and widths, the machines are capable of producing narrow-wide short warps for sample weaving as well as wide and long warps for production weaving. Additionally, the machines are not limited in terms of color repeat size compared to the limited color repeat size in sectional warping machines. Other features include automatic color change, short set up time of color sequence and desired number of leases via friendly user interface CAD system. Following the pre-programming and setting of the packages on the creel, the rest of the warping process is automatic, including the leasing for drawing-in and size rod separation. After the warping is completed, the beaming process requires the operator intervention to transfer the warp from the pattern drum to the warp beam.

Vandewiele NV, Belgium, unveiled Smart Creel at ITMA 2019, which is constructed with cells arranged in rows and columns as a matrix. The yarn is wound on each cell from large packages through a yarn feeder by a robot. At the show, the Smart Creel was feeding a VSi32 Velvet Smart Innovator jacquard. The length of warp pile yarn per each cell is preprogrammed according to the carpet’s design. Several creels and robots may be used to accelerate the warping process. The Smart Creel provides several advantages:

- eliminates human error with color arrangement in the creel;

- eliminates back winding of packages and the need for winders;

- eliminates downtime needed to load/reload the creel;

- reduces waste because of its smaller size compared to traditional creels; and

- reduces creel space because the bin’s size is much smaller than a wound package.

While the Smart Creel is intended for short runs or samples that may run back-to-back, the concept could be expanded for medium and long runs by increasing the size of the bins. Smart Creel can replace the traditional creel of a sectional and sample warper.

Vandewiele also exhibited the Fast Creel that was set-up with a new RCE2+ Rug and Carpet weaving machine. The Fast Creel controls each pile yarn individually using a servomotor that regulates the feed and tension of each yarn according to the pile length needed per the carpet design. The servomotor also functions as a stop motion when its yarn is down via smart sensing of its torque. This allows the pile yarns to be fed directly to the machine without the need to pass through a traditional stop motion, which saves time and allows fast creeling.

In addition, Vandewiele has developed the TEXconnect system for carpet weaving production that acquires data on the consumption of each pile yarn as well as tension and threading. The system also provides predictive maintenance. The combination of Smart Creel, Fast Creel, and TEXconnect systems, makes self-learning carpet weaving machines possible.

Tying-in And Drawing-in

Groz-Beckert KG, Germany, exhibited new automatic drawing-in machine, the WarpMasterPlus. This machine represents the latest generation of the company’s established drawing-in concept whereby the warp is drawn in from a single yarn package. However, the WarpMasterPlus adds features including two touch-screen monitors for two-sided control of the process, drawing-in of Duomix heddles without presorting, automatic heddle type setting, and easy maintenance and repair service. For drawing-in widths greater than 4 meters, Groz-Beckert can supply individual machine lengths as required.

Groz-Beckert also showed its different versions of KnotMaster automatic tying-in machines — AS/3, TS/3, XS/3Q, RS/3, RSD/3, 2s/3, and TS/3 TapeMaster — for a broad range of warp yarns including natural and synthetic, monofilament, textured, spandex, steel wire, fancy, glass and high-performance yarns, as well as polypropylene and polyester tapes. The machines are capable of double end detection from leased or unleased warps and are equipped with yarn break detection.

Switzerland-based Staubli International AG exhibited its known SAFIR 60 automatic drawing-in machine, as well as a new tying-in machine named TIEPRO. The most important feature of this machine is the method of yarn separation. Traditionally, yarns are separated using a needle, and a range of needles is required to handle separation for a variety of yarn types and sizes. The TIEPRO uses a small conical yarn separation mechanism and thus there is no need for needles.

Weaving Technologies

Germany-based Lindauer Dornier GmbH exhibited three A1 air-jet and two P2 rapier weaving machines producing a diverse range of fabrics for apparel, home textiles and industrial textiles at ITMA 2019. A P2 Type TKN 8/S G24/190 cm machine was weaving upholstery fabric and P2 Type TKN 4/E D8/360 cm was weaving coating fabric at a filling insertion rate (FIR) of 925 and 1,134 m/min, respectively. A 210-cm-wide A1 Type AWS 6/S G16 was weaving automotive upholstery fabric at 2,010 FIR, a 340-cm-wide A1 ServoTerry Type ATSF 8/JG was weaving Jacquard terry fabric at 2,184 FIR, and a 240-cm-wide A1 Type AWS 6/JG was weaving jacquard fabric for womenswear at 2,147 FIR.

Itema S.p.A., Italy, showed two A9500-2 air jet and four R9500-2 rapier weaving machines at one booth and at another booth; as well as one R9500-2, two Hercules, and one UniRap machine at the Itematech booth. Itematech is the former Panter company that Itema recently acquired. At the Itema booth, the air-jet A9500-2/340 cm was weaving bed sheeting and the A9500-2/190 cm was weaving apparel fabric. The four R9500 -2 rapier machines — in widths ranging from 190 cm to 340 cm — were weaving denim, shirting, jacquard upholstery and jacquard beach towels.

At the Itematech booth, machines were weaving filter fabric, geotextiles, heavy filter fabric and furnishing fabric. The UniRap machine, exhibited by Panter before joining Itema, is a single positive rapier. At ITMA 2019, the UniRap was weaving a furnishing fabric from linen warp and filling yarns in a form of spread tow with zero twist. The linear density of the warp and filling yarns was 1,000 tex, and warp and filling density was 0.67 threads/cm. To keep the warp yarn orientation flat, a special heddle wires with flat eyes were used. A weft feeder with rotating package also was used to keep the filling orientation flat without adding twist. This machine could be used to weave spread tows from high-performance fibers such as kevlar, carbon or zylon. It should be noted that the warp was fed by creel holding the packages of the spread tows. This setting does not require warping process since the total number of tows is not high.

Itema also introduced the Discovery, which was one of the main weaving attractions at the show. While the company referred to the weft insertion technology as “Positive Flying Shuttle,” the machine is shuttleless using stationary weft packages and filling yarn feeders, which are characteristic of shuttleless weaving. Thus, the machine is similar to a shuttleless projectile machine with gripper. Itema did not provide much information on the prototype other than hosting two demos per day and playing a YouTube video on a monitor by the machine. While a projectile is used as the filling insertion means, its acceleration is conducted by drastically different mechanism. As demonstrated in the video, the projectile is accelerated by a bar — termed “picking bar” — that moves horizontally in a groove. The bar contacts the projectile and moves it a certain distance to provide enough acceleration, then reverses its motion leaving the projectile with the filling yarn to complete the insertion. The contact between the picking bar and the projectile over certain distance and time could be to provide smoother motion with gradual acceleration rather than the sudden impact seen in a traditional projectile machine. Also similar to a traditional projectile, Discovery features several projectiles and the insertion is performed from the left side of the machine. The prototype on display at ITMA was weaving two side-by-side denim fabrics at a speed of 350 ppm, and Itema stated the Discovery can run at 400 ppm, which is similar to the speed range for traditional projectile machines

At its booth, Belgium-based Picanol exhibited 10 weaving machines. Five of these machines were air-jet machines — two OmniPlus-i-4-D-190 machines, one weaving a car seat fabric and the other a poplin fabric; one OmniPlus-i-4-R-190 weaving a parachute fabric; one OmniPlus-i-4-P-280 weaving a sheeting fabric; and one OmniPlus-i-4-P-190 weaving a bottomweight fabric. The other five on display were rapier machines — an OptiMax-i-4-R-220 weaving a denim fabric; an OptiMax-i-4-P-540 weaving an agrotextile fabric; an OptiMax-i-12-J-190 weaving a jacquard upholstery fabric; a TerryMax-i-8-J-260 weaving a jacquard terry towel; and an OptiMax-i-4-R-460 weaving a coating fabric. The range of the filling insertion rate for the air-jet machines was from 1,914 to 2,535 m/min; and for the rapier machines, with the exception of the two machines weaving jacquard terry and upholstery that were running at variable speeds as the design and filling yarn dictated, was from 1,456 to 1,485 m/min.

Nice Corporate Services, a Nigeria-based private company, is building a large vertically integrated textile manufacturing facility that encompasses ginning to finished fabrics. The project will reach its goal of producing 400,000 meters of fabric each day in various phases. The company has signed a contract with Picanol for various models of the OmniPlus-i air-jet weaving machines.

Picanol built the OptiMax-i weaving the denim fabric with near fully digitized filling insertion. The pre-winder is equipped with a programmable tension display (TED) with digital setting of the brake to control filling yarn tension during insertion. This design permits the user to store and monitor the ideal tension for a given filling yarn for future reproducibility. The machine also is equipped with an Electronic Right Gripper Opener (ERGO) that is electronically controlled to digitally set the gripper opening to minimize the length of the filling waste at the right selvage of the fabric. Additionally, the machine is furnished with the QuickStep filling presenter that allows digitally programming different timings for filling presentation, insertion and rest. These features, along with already established digitized weaving efficiency and stop — warp, filling, and other stops — data acquisition, a self-learning machine is possible if big data analysis and artificial intelligence can be added to make the machine Industry 4.0 compatible.

Italy-based Smit S.r.l. exhibited five machines. Four machines were shown at its stand and one machine was on display at the Vandewiele booth. The latter machine was the single rapier ONE with 190 cm reed width and free flight system — no guide is required to support the rapier during weft insertion — weaving intricate upholstery fabric at 380 ppm, or 722 m/min FIR.

The other four machines were:

- New model GS980 with 360 cm reed width weaving a jacquard bed sheeting at 360 ppm, or 1,296 m/min FIR, using a Bonas jumbo jacquard with 27,648 hooks — the highest exhibited at this show;

- Model GS980 machine with 220 cm reed width weaving a man-made sportswear dobby fabric at 550 ppm, or 1,200 m/min FIR, that featured a new device termed 2SAVE, which eliminates auxiliary selvages from both sides and allows the cut weft to be recycled;

- Model GS980 machine with 280 cm reed width and equipped with a Staubli 6144 jacquard head weaving jacquard terry fabric at 289-320 ppm, or 809-896 m/min FIR; and

- Model FAST weaving machine with 220 cm reed width and double free flight rapier producing denim fabric at 700 ppm, or 1,540 m/min FIR, which is high speed for free flight.

At ITMA 2019, Japan-based Toyota Industries Corp. exhibited JAT 810 air-jet machines that were shown at ITMA 2015. Three were demonstrated — a JAT810 8T-280ES-ET weaving three side-by-side bath towels; a JAT810 6SF-340DE-EF weaving curtain fabric; and a JAT810 4F-190EC-EF machine forming upholstery fabric. Additionally, the company showed a new machine introduced as the “JAT New Concept” air-jet weaving machine. The company indicated that this is its next-generation air-jet machine looking ahead of automation, smart factory and eco-technology.

Japan-based Tsudakoma Corp. showed three ZAX9200i Master air-jet Looms at ITMA 2019. One of the machines, a ZAX9200i-190-2C-C6, was weaving industrial fabric using fine 33dtex polyethylene monofilament both warp and weft directions at 1,200 ppm, or 1,872 m/min FIR. Normally, water-jet weaving is used for fine monofilament filling insertion.

The second machine, a ZAX9200i-190-4C-D16, was weaving interior upholstery fabric at 1,300 ppm, or 2,219 m/min FIR. The third machine, a ZAX9200i-Terry-280-8C-J, was weaving three side-by-side jacquard terry fabrics at 1,000 ppm for terry sections and 750 ppm for the border sections, or 2,596 and 1,947 m/min FIR, respectively.

At the recent ITMA, weaving speeds and FIRs did not vary much compared to previous ITMA shows confirming the fact that they have potentially reached the upper limits. As seen at previous shows, the focus of the weaving machine manufacturers was on the diversity of their products. With a variety of weaving machines available, manufacturers demonstrated their machines’ capabilities to weave for the three markets — namely apparel, home textiles and technical textiles.

Narrow Weaving For Smart Applications

At ITMA 2019, Switzerland-based Jakob Müller AG showed its narrow weaving machine NFM® equipped with the Multi Directional Weaving (MDW®) functional and effect thread placing device.

The machine was weaving fabric containing two electrically conductive yarns from blend of polyester and copper/silver electronic yarns (e-yarns). The two yarns were moving independently from the main shedding motion each aided by a guide. A strategic motion can be preprogrammed to raise the e-yarns out of the reed — an open reed or comb — move to either side specified distance and picks, and lower to interlace with the weft yarn. The calculated movement of the e-yarns’ guides results in the formation of an area covered with electrically conductive yarns distributed over the fabric surface with desired pattern. The copper and silver are antibacterial and electrically conductive materials and products with such features may be used as shoe liners for heating. Fabrics with electrically conductive circuits may be used to connect devices in electronic textile that have range of applications.

Three-Dimensional Weaving

At the recent ITMA, more companies contributed to the field of 3D weaving than at previous shows. VÚTS a.s., the Centre for the Development of Engineering Research, Czech Republic, showed a new air-jet weaving machine dedicated to weaving 3D distance fabrics with constant or variable distance between the top and bottom ground fabrics. Two warp beams are used — one to feed the warp sheet for the top and bottom ground fabrics and the other to feed the pile warp sheet. Potential applications for the distance fabrics include inflatable boats of different types, docks, mats, flood protection and lifting bags, among other applications. Currently, the inflatable boat industry is using a drop stitch technique to distance two fabrics that will be laminated post drop stitching. Numerous needles are used for joining the two base fabrics. The drop stitch machines and setting procedures are complex and lengthy, and the process may take more than 20 days to remove and replace the needles. The distance fabrics produced using the VÚTS weaving process are much faster and easier to design and form with the desired geometry.

England-based Optima 3D Ltd., a new company formed in 2018, has designed and developed a range of 3D weaving machines for formation of preforms for the composite industry. Its Optima 500/150 uses a shuttle system for weft insertion and a jacquard shedding system with electronic user interface for structure parameter input that provides preform design flexibility.

Dornier also offers composite systems that include 3D weaving for multilayer preforms for composite applications. The features of its machine include a CAD system to program the weave structure, a rigid rapier filling insertion system, individual warp yarn control jacquard shedding system, creel for feeding warp yarns from wound packages, and an optional horizontal take-up system for thick preforms.

Very skilled woven designers with a deep understanding of 3D fabric geometries generally are required to create 3D textiles. The need for CAD systems that are intuitive and easy to use to develop 3D fabrics is sorely needed. Germany-based EAT GmbH recently introduced its 3D Weave Composite Software. The warp or the weft cross-section is drawn digitally on square paper along with information on warp and weft yarn size and color for each warp layer via user interface. Then the system provides colored a 3D visualization of the structure. The software then converts the design to traditional up and down motion of each warp yarn to weave with one shed at a time on a weaving machine.

Road To Industry 4.0

Although weaving machine manufacturers have made progress toward producing digital machines that are Industry 4.0-ready, more still needs to be done. Weavers are looking for machines with automatic warp break repair; a fully automated start mark prevention mechanism that does not need operator intervention; fully automated style changes; automatic formation of flexible integrated circuits for smart e-textiles; multiphase weaving machines for dobby and jacquard weaving; and variable width/warp density jacquard weaving to overcome the current speed limit of single-phase weaving machines.

The road to Industry 4.0 also requires systems to collect and store large amounts of digital data, use of IoT to allow machine manufacturers to access and process big data using AI and analytics to diagnose and predict disruptive issues, development of robotics to complete automation, etc. It should be pointed out that the upstream yarn manufacturing and downstream — fabric finishing, conversion to products, and marketing — should be integrated with weaving since all data are correlated starting from fiber and ending with the market. One major issue manufacturers are concerned about is the compromise of data and intellectual property (IP), which is an impediment to the road to Industry 4.0. The textile industry is global and diversified and there is a need for global laws to protect manufacturers’ data and IP from hackers.

Editor’s Note: This article was adapted for Textile World from a paper by Dr. Seyam that was published in the NC State Wilson College of Textiles’ Journal of Textile and Apparel, Technology and Management (JTATM). The original paper may be viewed here: http://bit.ly/2020weaving

March/April 2020