I

n recent years, the term “nanotechnology” has spread across the globe like wildfire.

Millions of dollars in research grants and investments are being devoted to making products less

than 100 nanometers in size. Unlike many other aspects of the US textile industry, which face

considerable pressure, nanotechnologies are generating significant interest.

Within the past decade, the industry has rediscovered and continues to develop technologies

that enable production of extremely small fibers – nanofibers – using a process called

electrospinning.

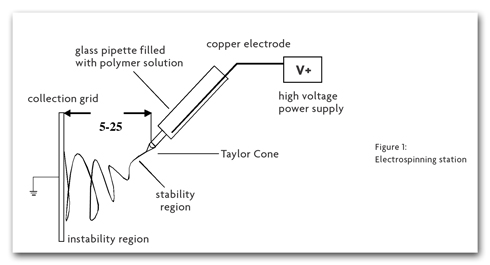

The Electrospinning Process

Electrospinning is not by any means a new discovery. Its roots go back to the early 1930s,

when the first patent was issued. Simply stated, electrospinning is a process that uses the

electrostatic attraction between a charged polymer and a grounded or oppositely charged collection

plate to produce extremely fine fibers ranging in diameter from less than 10 nanometers (nm) to

several micrometers. Recent developments have shown it can be performed on polymers both in the

molten state and in solution.

The polymer is held in a syringe or other type of container

(See Figure 1). The charge can be applied directly to the syringe so that when polymer

passes through, it receives a surface charge similar to that applied to the syringe. As the voltage

to the system is increased, the strength of the electric field generated eventually becomes greater

than the viscoelastic properties and surface tension of the polymer, and a tiny cone – often

referred to as a Taylor Cone – is formed.

Further increasing the electric field’s strength will deform the Taylor Cone until a fine

fiber is extruded from the cone’s apex. When working with solutions, this strand will continue as a

stable jet for a short period of time before the instability or whipping region occurs. This region

further decreases the fiber’s diameter as the solvent evaporates from the solution, leaving an

extremely small fiber. It is important to note that due to a much higher viscosity and lack of

solvent evaporation, fibers electrospun from the melt do not undergo an instability region and as a

result have much larger diameters.

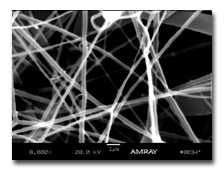

Electrospun fibers typically have been collected as a random nonwoven mat, and most of the

applications developed today reflect this configuration

(See Figure 2). However, advancements in collection techniques continue to be a major

focus of research. As a result, it is possible to collect aligned continuous fibers that can be

twisted to form yarns composed of nanofibers.

Figure 2: A scanning electron microscope (SEM) micrograph showing electrospun polylactic

acid glycolic acid (PLAGA) nanofibers

Nanofiber Applications

It is one thing to successfully produce nanofibers, but it is more important from an

economic standpoint to find a suitable application for them. One of the main goals for nanofibers

has been to produce the strength they should theoretically possess. In conventional fibers produced

today, there are fairly defined limitations to the percentage of crystallinity that can be obtained

in a fiber/yarn form.

Another potential benefit of nanofiber technology is the tremendous increase in

surface-area-to-weight or -volume ratios. The lure of nanotechnology stems from the possibility of

redefining these limitations.

For example, the actual thickness of a carbon/carbon bond is approximately 1 nm. If a

5-nm-diameter fiber is produced, the molecular chains are effectively forced to align in a highly

crystalline manner. Ideally, the resultant strength of the fiber produced will be determined by the

strength of the carbon/carbon bond in the molecular chains of the polymer.

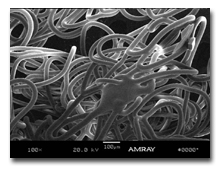

Figure 3: SEM micrograph example of a nanofibrous mat

Varied Applications

These advantages of electrospun fibers make them very appealing for a broad array of

potential applications in many industry segments. The composites industry is especially interested

in nanofiber technology because it potentially allows the creation of products that are much

smaller and lighter in weight, yet capable of performing at the same or enhanced mechanical

standards compared to traditional composites. If the fibers can be collected individually and

aligned to specific orientations, it is possible to increase the maximum volume fraction of fibers

in a matrix, thus increasing the material’s strength. The increased surface-area-to-weight ratio

also will allow for improved bonding with the matrix to help prevent failure due to pullout

of the fibers.

In addition to the composites industry, the filtration industry has begun utilizing

nanofibers, and in some cases has generated commercially available products. Nanofibrous mats,

similar to that shown in Figure 3, can be made with varying fiber diameters based on several input

parameters. With differing fiber diameters, the pore size of the mat can be controlled to a fairly

high degree. As a result, nanofibrous mats can be designed to block out molecules of specific

sizes. In addition to mechanical filtration as described above, nanofibrous mats can be treated so

that when molecules of specific design pass through, a chemical reaction takes place that

neutralizes any potential hazards.

Similarly, nanofibrous mats are being explored as biomedical grafts and wound dressings. It

has been found that cells can adhere to and proliferate into the mats with a great deal of success.

Also, because of the extremely small size of the nano-fibers, the potential exists for layering of

different polymers with specific functionalities. Electrospinning techniques can be applied to

nearly every polymer of sufficient molecular weight, including those that are Food and Drug

Administration-approved, thereby limiting issues of biocompatibility.

The application of nanofibers is not aimed only at specialized industries involved in

technical textiles. The introduction of microfibers into traditional textile markets

has created a wave of new garments claiming stain resistance and extremely soft hand. The

introduction of nanofibers and nanocoatings can take apparel innovations further. For example,

man-made cashmere has been developed with a softer hand than that of worsted wool, offering the

feel of cashmere at a fraction of the cost.

The Future Of Nanofibers

One of the greatest attributes of electrospinning and nanofibrous technology is that it is

still in its infancy. Numerous ideas and concepts have been proposed, but in many cases, the

theoretical expectations have yet to be realized. It has been shown that nearly every polymer

imaginable can be electrospun from either solution or melt, so there are no limitations in that

regard. Today, the fibers are collected in the form of a mat of staple-aligned fibers. Future

developments and processing technologies must find a way to orient a continuous fiber for the

technology to advance in the right direction. It has been shown that electrostatic attraction and

repulsion can be used to control the path of the jet. With enhanced methods, it may be possible to

produce woven or braided fabrics directly from the electrospinning station. While the process

awaits mechanical and processing mechanisms that are capable of maneuvering single fibers into

specific configurations, much work still needs to be done to optimize the conditions for making a

specific fiber diameter with a specific polymer. Only after the process can be controlled will the

technology be ready for full optimization and full realization of electrospinning capabilities.

Editor’s Note: Jason Lyons and Jim Kaufmann are affiliated with Philadelphia-based NovaComp

Inc. The authors wish to thank Drexel University, Philadelphia, for use of the scanning electron

microscope, and Frank Ko, Ph.D., for his assistance, both educationally and financially.

August 2004