Set to be worth $6.65 billion by 2030, the digital textile printing market has no doubt gained traction in recent decades, fueled by technological advancements that have helped to increase efficiencies and drive the industry forward. Today, however, with digital printing technology now the industry standard, textile printers are having to work harder than ever to push the boundaries of creativity and achieve true product differentiation. Regardless of designs or fabrics, the end result for textile printers to date has essentially been much of the same market-wide: a two-dimensional pattern that exhibits the same mechanical properties as the substrate textile. Looking to the future, it’s clear then that the next creative and commercial move for textile printing needs to go beyond just improving current processes to truly bring textile to life and reimagine what’s possible — which is precisely what direct-to-textile 3D printing is now delivering.

The world of fashion and textile is no stranger to the 3D printing process itself. 3D printed elements have been incorporated into textiles before, by first 3D printing the desired element then manually working it into an individual garment. We have seen elaborate 3D printed elements being used to elevate dresses and create show-stopping shoes for years, with esteemed designers from Iris van Herpen to Julia Koerner, Karim Rashid and Neri Oxman embracing the technology. This process, however, has for the most part been limited to the highest end of fashion and for conceptual and artistic endeavours.

The world of fashion and textile is no stranger to the 3D printing process itself. 3D printed elements have been incorporated into textiles before, by first 3D printing the desired element then manually working it into an individual garment. We have seen elaborate 3D printed elements being used to elevate dresses and create show-stopping shoes for years, with esteemed designers from Iris van Herpen to Julia Koerner, Karim Rashid and Neri Oxman embracing the technology. This process, however, has for the most part been limited to the highest end of fashion and for conceptual and artistic endeavours.

Tech And Style For Textile Printers

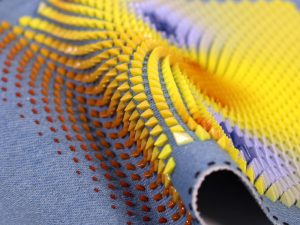

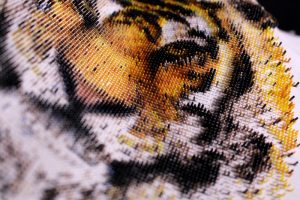

Fortunately, new advances in the technology are now taking this process even further — both reinventing what is possible and, importantly, putting these revolutionary capabilities directly in the hands of textile printers, ultimately ushering in an entirely new era of textile printing. For the first time, we are now able to 3D print direct-to-textile, opening up a host of new opportunities. By enabling the construction of patterns and objects directly onto textiles such as denim, cotton, polyester and linen, it is possible to build 3D printing into textile production from the outset, effectively turning fabric into a blank canvas for new visual and tactile effects.

While direct-to-textile 3D printing technology is relatively new to the market, early applications have already included decorative patterns on jeans and dresses, graphics on shoes, wearables and bags. With countless more potential creative applications still to be explored this is merely the beginning.

While direct-to-textile 3D printing technology is relatively new to the market, early applications have already included decorative patterns on jeans and dresses, graphics on shoes, wearables and bags. With countless more potential creative applications still to be explored this is merely the beginning.

Landmark pieces such as the Greta Oto Dress designed by threeASFOUR and Travis Fitch are showcasing how 3D printing onto textiles can create never before seen textile designs. Exploring the interplay of light and fabric, the dress harnesses the lenticular effect of the 3D printed elements — printed directly onto a polyester substrate — to reflect and refract light creating a butterfly-like shimmer — ultimately resulting in a final product that simply couldn’t be produced by any other means.

Direct-to-textile 3D printing not only allows innovation in new products, but can even extend product lifecycle by enabling used clothing and accessories to be repurposed with the addition of 3D printed elements, including customized designs and one-of-a-kind personalization.

Looking beyond the surface, the true value of this technology grants textile printers the means to deliver a differentiated, stand-out service offering. Changing the way they can engage with fabrics, this opens the door to new revenue streams and provides an all-important critical edge in a competitive market landscape.

Editor’s Note: Naomi Kaempfer is creative director of Art, Design and Fashion at Stratasys, and is responsible for exploring innovative new applications for 3D printing across the creative disciplines and developing key collaborations with designers and artists to push the creative envelope.

June 26, 2023