S

pinners continue to report good and stable running conditions. At least two mill

executives mentioned running full, seven-days-a-week schedules at all their plants. Yarn supplies

remain tight, and some mills actually are turning away business.

“Running conditions right now are pretty good, but I’m starting to see a little slowdown,”

said a multisystem spinner. “I think we will start seeing the effects of some of the Asian imports.

Business in the third and fourth quarter to the degree that we see is still unknown. A lot of that

depends on the [China] safeguards.”

The outlook seems solid across most markets. Automotive looks positive, with greater poundage

projected for the second half of 2005. Medical, apparel and industrial markets all seem to be

running well. Soft spots include upholstery and socks. Upholstery is struggling because of

increased upholstered furniture and upholstery fabric imports. Hosiery also has import issues,

especially for low-end cotton socks.

“We still feel pretty bullish,” said an open-end (OE) spinner. “We are looking at running

strong through the 4th of July. Our shipments are exceeding our production, and our inventory has

dropped 35 percent. We have got some replenishing to do. I’ve got programs that go on out well into

the third quarter.”

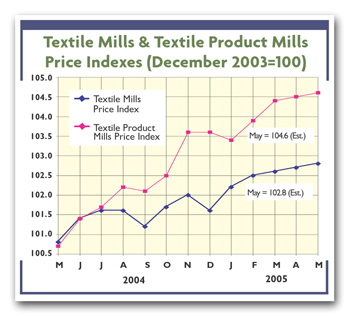

Cotton prices are beginning to move upward after dipping a bit. Short supply has kept yarn

prices up during the dip.

DR-CAFTA Support

Spinners surveyed reported strong export business with Central America. A ring spinner said

exports account for more than one-third of his business, with more growth expected. An OE spinner

said his company’s export business is stronger than ever, and looks likely to continue.

“Our export business in Central America continues to grow, with significant potential,” said

a specialty ring spinner. “But growth requires us to better manage the obstacles of customer credit

and product lead time.”

Recently, the National Council of Textile Organizations (NCTO), Washington, decided to

support the Dominican Republic-Central American Free Trade Agreement (DR-CAFTA). Most of the

spinners contacted this month seemed to agree with that decision.

“We’re supportive of CAFTA with the [NCTO] amendments concerning pocket linings, [trade

preference levels] and cumulation,” said an OE spinner. “The whole point was Washington wanted to

hear one voice coming out of the textile industry, but it’s becoming fragmented again,

unfortunately,”

(See “

Textile World News,”

TW, this issue).

“In my mind, there will have to be some type of agreement with the Central American

countries,” said a ring spinner. “If you talk to someone in California, they are dealing with

Central America. If you talk to someone in New York City, they are dealing with Central America.

Someone in your backyard is probably getting fabric or shipping yarn down there.”

Little Phase-Out Fallout So Far

So far, spinners are not seeing much impact from the textile quota phase-out.

“Since the first of the year, we’ve had one major customer that has gone out of business,”

said a ring spinner. “Is that directly related to the textile quotas? I’m not sure. As far as

volume is concerned, we’ve been very pleasantly surprised. I don’t know if it is a function of all

the spinning production that has been taken out over the years or just a situation where we’ve been

able to put together some good orders.”

Another spinner said he has not yet seen any impact from the discontinuation of quotas, but

still feels “it has to be out there.”

CITA Too Slow

Most spinners voiced little interest in the China safeguards, viewing them at best as stopgap

measures. The sluggish pace set by the Committee for the Implementation of Textile Agreements

(CITA) in moving ahead on considering safeguards seems to have undermined confidence in CITA’s

decision-making process

(See “

Textile World News,”

TW, this issue).

“It’s a short-term fix if we can get it,” said one spinner. “Maybe it has created a

little bit of doubt among retailers about whether they can source everything they might want to

from China. That might explain the current level of business.”

June 2005