After some problems, not unlike many other textile machinery suppliers, the Italy-based weaving

machinery manufacturer itema S.p.A. has recovered. The owner of the famous brand names Sultex,

Vamatex and Somet has presented a new rapier machine, which already is enjoying some commercial

success around the globe.

Some weeks ago, itema held an open house to present its new R9500 rapier weaving machine. CEO

Carlo Rogora started his presentation by saying: “Today, itema is one brand and one name. In the

past two years, we did our homework. All the labels are now under one umbrella: ‘itema.'”

The company has been restructured, and the personnel count in Italy and Switzerland was

reduced from 1,200 people in 2009 to 825 in 2012. On top of that, Rogora mentioned, itema today is

absolutely free of debt. Frankly speaking, this is quite a remarkable feat for a textile machinery

company these days.

After the response to the ITMA Barcelona debut and the immediate market success of the

air-jet A9500 weaving machine, the concept of the R9500 was obvious: the company is taking

advantage of a Common Base Platform (CBP) and integrating the successful features of its rapier

machines. The R9500 is based on the A9500’s footprint and mechanical concept, and also makes

efficient use of comparable parts and solutions.

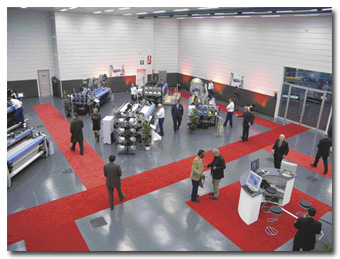

itema recently held an open house at its showroom in Colzate, Italy, to introduce the new R9500

rapier weaving machine.

Versatility

The versatile R9500 should enable weavers to enter new markets. Users have the flexibility to

select various options and features, which enables a broad application range. The machine’s

appearance is solid and robust: It can weave very heavy fabrics, but it is flexible and precise

enough to weave fine, fancy and technical yarns.

The SK Transfer System is designed to provide high speed and versatility, while the new Free

Positive Approach (FPA) weft transfer provides a race board without guiding elements for use with

man-made or delicate yarns.

The New Common Electronic Platform features a simple but comprehensive design and allows all

technical parameters to be easily controlled. More than 75 percent of all key components are said

to be Italian-made. More than 90 percent of all parts – including motors, electric devices and

interface – are used on both the rapier and the air-jet machine A9500, which lowers costs for

customers that have both technologies.

Sturdy Frame

The R9500’s heavy-duty frames provide a low vibration pattern even at high speeds. The solid

drives, positioned in main lateral frames, are said to be engineered for extensive control of

moving masses to consistently process heavy patterns or unbalanced styles with minimal cost and

maintenance. The redesigned sley and back rest modules represent key developments. The new sley

design promotes speed and versatility, while the new back rest module enables reduced warp tension

and a cleaner shed break. Maximum floor space utilization provides low power consumption and a

minimal noise profile.

Easy Style Change

The R9500’s design should reduce downtime for style changes by eliminating time-consuming

maintenance and settings. Quick beam release is standard, and DRC10 connections eliminate the need

for leveling. The number of machine covers has been reduced, allowing quick access for machine

cleaning and maintenance, resulting in reduced heat in the workshop.

itema’s new R9500 rapier machine is based on the A9500 air-jet machine’s footprint and

mechanical concept.

Weft Insertion System

The machine’s new shed geometry is the result of the need to reduce the shed to maximize

speed and to use rapiers with diverse capabilities. Further features are the positioning of the

first frame closer to the reed. This allows a shortened stroke, which enables higher speeds and

longer life cycles for heddles and harness frames. Furthermore, the beating stroke has been

increased to ensure the highest beating force and the capacity to weave heavy fabrics.

Rapier Drive System

The Turbo Prop propeller drive system has been completely redesigned for the R9500. The drive

is still compact and has minimal moving parts, providing reliability and reducing maintenance. The

drive design also features a secured mechanism in the side frame to ensure stability and precision,

as well as new carriage and swinging sliders made using aeronautical-grade alloys. In addition, the

new Turbo Prop settings do not shift over time, eliminating the need for maintenance personnel to

continually reset and adjust them.

Additional Equipment

There is a wide range of options for selvage formation. Standard cutters, a melting device,

and mechanical and air tuckers can be installed. Electronic weft tensioning can be specified. The

tensioner can be programmed through the user interface, and it features a self-cleaning system to

prevent dust accumulation. The R9500 weft control system enables each weft to be processed

digitally by the NCP Processor. Sensitivity adjustments are determined according to each individual

position.

The R9500 is equipped with a new electronic platform in which the full-color touch screen is

the user interface. The software is intuitive and encourages dialogue with the weaver. By accessing

the touch screen, the weaver may select a functionality test for any device or application on the

machine, including circuit boards. The optional Intelligent Production Optimizing System (IPOS) is

designed to optimize machine productivity by monitoring machine speed and stop level.

The Vision

Rogora mentioned that itema is still the only supplier to provide all weft insertion systems

– air-jet, rapier and projectile technology. After some industrial trials in pilot mills, the R9500

is already having some success. The Quality, Reliability and Performance (QRP) certification with a

two-year guarantee reflects itema’s commitment to quality through the consistent application of

enhanced processes to design, develop and manufacture.

January/February 2013