Within any specific market, a number of trends and influencing factors are catalysts for changing

needs and higher performance requirements. The medical field is no exception to this rule, and

advancements in medical technology itself, the demographics associated with an aging population and

the onset of chronic disease states — like diabetes and obesity — play a huge part in the market

dynamics.

Technology advances are the area in which raw material suppliers have the greatest influence

and impact, specifically because material advances to support the shifting needs are most dominant

where there is investment in research and development. The success in delivering new, smarter

materials — along with necessary customization to meet an end application requirement, as well as

the scale-up to production via a fully commercialized manufacturing process — are all influenced

greatly by the customer’s need and acceptance of new products, including the willingness to pay for

the improved performance characteristics. The term “intelligent textiles” — interchangeable with

“smart” or “active” textiles — refers to textile materials or engineered structures that are

potentially able to sense, react and/or adapt to environmental conditions.

Marjan Kooroshnia, Ph.D., The Swedish School of Textiles, has printed surgical facemasks using

thermochromic inks that change color in response to a rise in temperature of the wearer’s

breath.

Recent impacts on raw material costs, along with manufacturing energy requirements and

transportation costs, have all influenced desired technology advances of late. For example,

alternative sources of raw materials are actively sought, as is the ability to reduce weight or

bulk, thereby minimizing transportation costs. The potential range of uses for medical textiles

continues to increase, nevertheless, and the need to understand and improve upon the performance of

these materials and to target specific applications becomes important. From the accreditation

process network to the creation of green and clean medical fabrics to the utilization of

nanofibers, the use of textiles in medical applications has become even more complex and

challenging. However, an underlying driving dynamic influencing how unmet needs are addressed in

the medical markets necessitates a linking together of principles from different disciplines.

Mobile Applications Raise Standards And Expectations

In the world of medical technology, instantaneous access to critical data enables lifesaving

decisions to be made sooner. Previously, a passive approach was acceptable, and clinicians and

healthcare workers were satisfied essentially to react to lagging external indicators. Now, with

many products being largely in contact directly with the surface of a patient through the skin, the

overarching movement is to position such products for more dynamic behavior. This raises concerns

as to how such materials can become more active, intelligent and dynamic components within a

surgical procedure; or can replace a routine examination for bedridden patients. In addition, such

features enhance the product’s value beyond its being simply a means to create a passive protective

barrier per se, or a disposable commodity-based product.

The maturity of the medical apparel market means that future growth is becoming progressively

more dependent on product innovation. The importance of new features, such as improved comfort and

conformance with high performance thresholds, provided at minimal cost, has never been more

essential. Several stages in smart textile development can be described; they include smart

textiles that have only a sensing function; smarter textiles that have both sensing and actuating

functions; and smartest textile systems that are able to respond and adapt their behavior to the

environment.

Table 1 highlights several areas of opportunity ranging from the current state of technology

to what could conceivably be available in five years or so. For example, Teresa Wagner, technical

leader – composite solutions, Owens Corning Science & Technology LLC, Granville, Ohio, recently

discussed the potential for carbon-enhanced reinforcements in engineered materials to provide an

effective means to create an electromagnetic shield and, in so doing, the ability therefore to

create thin, lightweight, highly conductive materials with complex geometries. So, in addition to

the current use of conductive materials in textile applications as antistatic materials, or for

heating, or for electromagnetic interference shielding as Wagner described, they will now have the

ability to transport electrical signals to or from sensors embedded therein, thus providing

additional capabilities for active intelligence and the ability to react to external stimuli in a

dynamic manner — for example, to changes in body vital statistics during surgeries.

Opportunities For Improved Products

There are numerous types of smart materials, some of which are already routinely available,

although still in development for many medical applications owing to the regulated and controlled

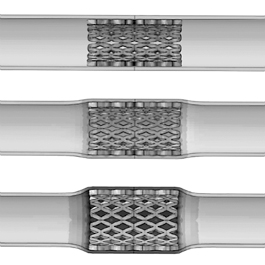

environment. For example, shape memory polymers (SMPs) have been used already for a variety of

biomedical applications and temperature-responsive polymers, including in implants such as

cardiovascular stents, thus allowing minimally invasive implantation through small incisions or

natural orifices while the stent is in its small temporary shape before it expands and reshapes

itself to fit the required clinical specifications and perform accordingly. In addition, such SMPs

have an additional feature — that of biodegradability, which results in the implant degrading

before elimination by the body after it has fulfilled its purpose.

Surgical sutures are another good example of SMPs that enable wound closure with self-adjusting

optimal tension. This characteristic reduces tissue damage due to the potential for over-tightened

sutures; and, furthermore, it supports improved healing and the regeneration of tissue.

There are many chromogenic systems available that rely typically on the inclusion of chromic

dyes, pigments or coatings. Halochromic systems, in which color change is brought about by pH

value, have been shown to provide valuable visible sensors for use with burn patients. The pH

values vary throughout the healing process; hence, wound healing can be monitored without the need

to disturb the dressing and, therefore, the wound bed itself. In addition, halochromic textiles can

be used in geotextiles or protective apparel to indicate environmental pH changes brought about by

contaminated atmospheres. Thermochromic textiles generally include embedded organic compounds that

operate between the ambient and body temperatures and characteristically react to heat. They are

used extensively for thermodiagnostics and as skin thermometers.

In addition, thermoelectric materials can be used to build devices that convert temperature

differences into electricity, and vice-versa.

Self-healing materials have the intrinsic ability to repair any damage due to normal usage,

thus expanding the material’s lifetime. Many orthopedic implants fail following accumulation of

micro-damage sustained over lifetimes of cyclic loading. The bone cement — consisting of a

poly(methyl methacrylate) (PMMA) base — used in these procedures has been a topic of an initial

study for self-healing materials and provides an example of how embedded microspheres embedded

within the PMMA can accomplish the repair. The microcapsules rupture and release their contents

into the areas where the micro-cracks form; polymerization of the released water-reactive healing

agent, a medical-grade cyanoacrylate tissue adhesive used in biosurgery, will serve to halt crack

propagation and restore the material’s strength. Barrier technologies for textiles and engineered

materials could incorporate similar embedded technologies to heal/repair breeches, tears or

scalpel/needle sticks.

This computer simulation shows how a stent made with a shape memory polymer expands into

place after insertion. The research was conducted at the Massachusetts Institute of Technology by

Lallit Anand, Ph.D., Warren and Towneley Rohsenow Professor of Mechanical Engineering; Vikas

Srivastava, Ph.D.; and graduate student Shawn Chester.

Path Forward: What’s Next?

During the past several years, medical device companies have been interested in assessing the

importance and impact of personal protective apparel. In broad terms, this article has focused on

the need for research and development in smart and active textiles to support the advancing

requirements of improved protective apparel. The primary targets for the advancements may be

surgical gowns and drapes as well as infection control apparel — products used widely in the

healthcare environment to protect healthcare workers, clinicians and patients alike from

transmitted infections. Yet, the smart and active concept can be leveraged to other markets such as

advanced wound care and other diagnostic systems, filtration and hygiene, fire and hazard

protection, and potentially also automotive and construction uses. This article has contrasted the

sophistication of materials in use to meet demands of performance and comfort with ideas for new

features that can be developed to influence future trends and address unmet market needs. Smart

textiles for healthcare and resulting medical applications are routinely the result of joint

developments made in many technologies — not least via advances in material science, information

technology and engineering; but also medicine itself.

Editor’s note: Vicki A. Barbur, Ph.D., works with leading-edge companies in their efforts to

spur, track and manage innovation through portfolio management and technology partnering. She is

based in Chicago.

November/December 2012