TW Special Report

Luannan Deshun Spinning Mill produces Ne 10 recycled cotton soft knitting yarn on semi-automated rotor spinning machines. Located in Tangshan City, Hebei Province, China, the company sells its highly appreciated yarns mainly to customers in Foshan City, Guangdong province and other local areas. The company needed to expand the existing mill set-up of about five to six tons a day to meet the huge demand for recycled cotton yarns. Therefore, Deshun was looking for an efficient rotor spinning machine that could handle the challenges of recycled raw materials and keep up with the market’s fast pace.

The Challenge

The processing of recycled cotton tends to cause higher numbers of ends down. The unstable quality resulting from the material and the opening can cause problems in the downstream processes. The challenge is to get the maximum yield from the given material with the optimum settings and technology. Spinning mills using recycled cotton as a raw material need to find the optimum balance between high production, good yarn quality, high raw material yield and low operating costs.

The Solution

Based on the raw material data and the existing fiber preparation it was obvious, that the Rieter semi-automated rotor spinning machine R 37 would be the best solution. The spinning box of this machine offers decisive advantages in processing recycled cotton thanks to a higher level of trash extraction. Short fibers are guided well in the feeding and opening areas and most trash, neps and yarn ends which are not fully opened are removed. More good fibers are kept in the spinning process than with other machines. This guarantees better evenness and IPI values which results in lower ends down rates and in economic production. The low energy consumption of the R 37 further reduces the customer’s operating costs.

The Customer’s Benefits

The Customer’s Benefits

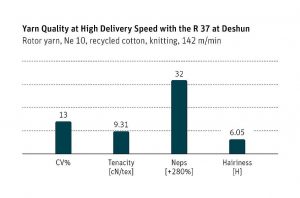

The R 37 produces Ne 10 recycled soft knitting yarn with a delivery speed of 142 m/min. The overall efficiency of the machine is as high as 98 to 99 percent with fewer ends down and stable yarn quality. Deshun reports that the R 37 is more energy efficient and easier to operate compared to its former machines. There is no need to use tools when maintaining the spinning box. The rotor bearings can be lubricated without disassembly. Better fiber utilization and low energy costs increase the benefit. The company is proud of its effective mill management and good cost control. With the R 37 installation, Deshun achieved its goal of zero complaints from downstream customers. Even better, customers now pay a quality bonus.

January 27, 2022