The emphasis on quality continues as programs to lower cost press forward. Do it Right the First

Time and Six Sigma programs demand that manufacturers be able first to measure and define product

before they can take measures to improve it. Below are some of the testing and evaluation tools

available today. Lightfastness And WeatherabilityHow does an individual define product failure

It may be very different from the way his company, its customers, or its competitors define product

failure. The manufacturer must be able to set a standard and convince others that it has chosen

wisely. But whatever the definition, product appearance is going to be a very crucial factor. Thats

why lightfastness and weatherability are crucial. Even if a product resists fade in one

application, using it in a different environment can have a dramatic effect on durability. The

American Association of Textile Chemists and Colorists (AATCC), Research Triangle Park, N.C., has

worked for years with its members to carefully define the parameters that must be measured to

define consistent quality. Why do products fade and fall apart There are three major causes of

fading and degradation: light; heat; and moisture. Testing under accelerated conditions in a

natural environment or in a laboratory can determine a products long-term lightfastness and

weatherability. Natural exposure testing involves simply placing test specimens outdoors or

outdoors under glass. Location is very important. Q-Lab Weathering Research Service has locations

just outside Miami in south Florida and in the Arizona desert west of Phoenix, where products can

be professionally tested under rigorous natural conditions.

The Q-Lab Weathering Research Service near Miami is equipped to test products under rigorous

natural conditions. How do weathering professionals help a manufacturer determine how to test

The best rule of thumb is: simulate, and then accelerate. In other words, simulate the products

probable end-use, and then accelerate testing by exposing products to the most intense

environmental conditions available. Armed with this kind of information, the manufacturer is sure

to get a better nights sleep knowing its product can stand up to the worst the sun can dish

out.Most manufacturers rely on accelerated laboratory testers to answer their lightfastness

questions in a timely fashion. These tests can give fast, reproducible results. With the tremendous

increase recently in new technology, the use of accelerated weathering has increased

proportionately. The xenon arc test chamber is the most commonly used accelerated lightfastness

tester. Xenon provides the most realistic simulation of full-spectrum light because it includes

ultraviolet (UV), visible and infrared wavelengths. Xenon testers, such as the Q-Sun Xenon Test

Chamber from Q-Panel Lab Products, Cleveland, also can expose specimens to high temperatures and

moisture. Many xenon arc testers control the level of relative humidity (RH). This is important

because humidity can affect the speed and type of degradation that occurs as materials are

physically stressed trying to maintain a moisture content equilibrium with their surroundings.

Yarn Quality AnalysisLawson-Hemphill, Spartanburg, has introduced several products that

analyze yarn and yarn package quality.During the 1964 Knitting Arts Exhibit in Atlantic City, N.J.,

the company introduced the fiber analysis knitter (FAK) to check the quality of textured yarn

packages. Over the years, improvements have been made to this quality control instrument to

increase the volume and accuracy of testing without increasing labor man-hours. The latest

improvement has increased the volume of samples knitted by approximately 60 percent. Additional

attachments are available for spandex/elastane yarn insertion, thermal application and tension

measurement. More than ever before, the knitter knows when the problem is in the yarn.Even before

the School of Textiles at North Carolina State University (NCSU), Raleigh, N.C., initiated the

Quality Audit Program in 1959, mill managers and yarn spinners sought a consistent means of

evaluating quality of spun yarn. Requests at various times by the industry for comments on

qualities of textile materials, particularly yarns, created problems with no answers because

realistic standards or bases for judgment of quality were not readily available. Questions such as

How much variation should be present in various properties of a yarn began to arise. More

specifically: How good is a carded yarn How good is a combed yarn Is one yarn always better than

the other Can a combed yarn be of poor quality Just how poor can combed yarn qualities get Since

those early days, a number of lab instruments have been developed and are now coupled with

sophisticated statistical analysis packages. Life is now much better in the world of the yarn

spinner. Lawson-Hemphill recently announced a Yarn Analysis System (YAS) and has received patents

in China and Europe for grading yarn and simulating yarn in a package. YAS grades according to ASTM

International standards and correlates to the human eye.Using YAS as a yarn-clearing evaluation

system has increased production of both winders and open-end (OE) spindles. YAS will recommend that

certain faults are acceptable in a fabric and do not need to be cut out. This increases the

production efficiency of the winder and OE spindles. Less cutting means longer run time and

increased production efficiency. Lawson-Hemphill also has delivered the first Automatic

Package Analyzer (APA) for quickly measuring the density of a package. Using a camera with a new

lighting design produces the most accurate method of measuring the physical dimensions of any yarn

package. Once the test is complete, a green pass or red fail quickly appears on the computer

monitor. APA has reduced measuring time 50 percent compared with an earlier model.

Lawson-Hemphill’s Automatic Package Analyzer Color MeasurementEveryone knows the

customer looks at color first and foremost. Anything one can do to economically measure and sort

color will save money. The latest such device from HunterLab, Reston, Va., is the ColorQuest

XE-Touch. With technological advances has come increased performance at lower cost. Because of

ColorQuest XE-Touchs inter-instrument agreement, manufacturers can be confident that differences

between measurements are due to product color changes, not instrument variability. Whats handy

about the ColorQuest XE-Touch is a liquid crystal display (LCD) that uses touch-screen technology

for simplicity of operation and reliability. Prompts appearing on the screen are touched with a

finger to initiate the action. Commands such as prompts, measurements and mathematical equations

all can be customized.

Minolta’s CM-2600d is a portable, hand-held spectrophotometer.In another development, Minolta

Corp.s Instrument Systems Division, Ramsey, N.J., has introduced the worlds first portable,

hand-held spectrophotometer, the CM-2600d, which performs instant and simultaneous color

measurements using adjusted, included or excluded UV and specular (gloss) compensation. In

addition to these measurement capabilities, two unique Minolta patented features distinguish the

CM-2600d instrument from all other currently available portable spectrophotometers. First, the

CM-2600d performs faster and more accurate measurements of samples with gloss differences without

the need to change instrument setup or to reposition the sample. Thus, multiple measurement error

risks are minimized. The patented gloss measurement technology, Minolta says, simplifies

measurement operations and improves accuracy by providing simultaneous measurement of the Specular

Included and Specular Excluded components (SCI/SCE) of glossy and non-glossy samples. By acquiring

SCI and SCE data simultaneously, the user can discriminate both color and appearance differences

almost immediately from a single scan of the sample. A second Minolta patented advancement is the

instruments capability to provide simultaneous and precise adjustment of the UV component. This

feature eliminates mechanical positioning of UV cut-off filters and multiple measurements, and

replaces it with instantaneous calibration and adjustment of the UV energy in the light source. The

user can acquire simultaneous measured results for fluorescent samples including UV and excluding

UV. Automated Fabric InspectionSwitzerland-based Zellweger Uster, long known for fiber and

yarn analysis systems, has introduced the Uster Fabriscan for automatic fabric inspection. The

system automatically learns the fabric; and classes, maps and marks defects as small as 0.3

millimeters (mm).Israel-based Elbit Vision Systems Ltd. (EVS) plans to unveil the SVA Lite during

the Chinese International Textile Machinery Exhibition (CITME) in Beijing this month. The SVA Lite,

the second generation in shade-monitoring technology developed by EVS, is a compact, yet powerful

tool for monitoring shade in almost any process in which color is critical. Needing only 18 inches

in the machine width direction, the SVA Lite can be installed in even the tightest places in any

textile process.EVS has expanded the shade analysis tools that are available. The SVA Lite not only

provides side-center-side and end-to-end shade variation information in real time, but also

provides the ability to load standard swatch samples into a sample drawer on the side of its

chassis. This feature allows the user to compare shade readings not only to a point in the current

fabric being monitored, or even a past roll of fabric run, but to an actual standard shade

swatch.The quality tools of the SVA Lite do not stop when a lot is finished. The quality analysis

tools also include an automatic cut-planning tool, which will automatically input cut points in the

shade map (based on user-defined thresholds) to maximize shade uniformity within a shipping roll as

well as eliminate side-center-side shade off-quality. Once cut points are inserted into the shade

map, the SVA Lite 5-5-5 color-sorting software will automatically classify each cut by user-defined

5-5-5 color-sorting rules.The SVA Lite offers a flexible report generation environment that allows

shade quality summary information and statistics to be printed out, along with the 5-5-5 color

classifications on all cut rolls. Although very powerful by itself, the SVA can be combined with

the EVS I-TEX automatic inspection system to create a complete solution for quality monitoring of

both color and textile defects. Airflow MonitoringOne of the greatest misconceptions in

textile drying is that it is possible to produce consistent, high-quality, finished fabric simply

by monitoring zone temperatures and fan speeds. There are dozens of quality temperature-monitoring

systems on the market that can measure exactly how hot an oven is at any point. But the honest

truth is, all that heat is worthless if it isnt uniformly reaching the fabric. Airflow consistency

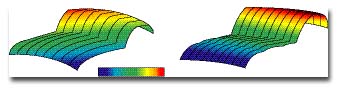

is the unsung hero of consistent finishing results. Consider the two examples shown in Figure

1. Its not difficult to guess which of the two fabrics illustrated is going to come out of the

oven with the exact same fabric characteristics across the width.

Figure 1 – Temperature profile across two fabrics in different ovens. These are before

and after shots of the same fabric, in the same oven, using the same process. The profile on the

left shows the fabric before the airflows were balanced, and the one on the right shows airflow

after balancing.The Sentinel airflow monitoring system from SimTek Inc., Greensboro, N.C., monitors

the airflow and offers suggestions for quick correction of the problem. A Remedies screen lists

possible correction in a logical order, thereby providing an expert to guide the operator to swift

remedies for the problem.Lastly, United Kingdom-based James H. Heal announced further uniform

calibration for the Nu-Martindale Abrasion and Pilling Tester, along with its Orbitor Pilling and

Snagging Tester and the Impulse Random Tumble Pilling Testers (See Out Of Control, TW, April 2002).

The inclusion of these additional instruments brings the total number of calibrations available

globally from Healink, Heals global technical service system, to 13 unrivaled in the testing

industry.These new product introductions in the area of quality control are exciting. They will

certainly help quantify differences and hopefully give buyers more confidence that what they

specify will be right the first time.

October 2002