NEWARK, Del. — February 1, 2021 — Waste handling equipment manufacturer Lundberg Tech, Newark, Del., has introduced the WasteTech Automated Cleaning Efficiency (ACE) trim and label waste removal system. Based on the company’s signature WasteTech All-In-One trim removal system, the WasteTech ACE automatically captures edge trim, label matrix, die cuts, and other waste materials at the machine along with any dust generated, cuts it into confetti, collects it in a bulk bag for recycling or disposal, and cleans the airstream through a built-in filter. The self-cleaning filter system continuously removes any dust and other particulates from the pneumatic conveying airstream to eliminate the line stoppages often required to clear waste from other trim systems, and promote efficient, non-stop operation.

NEWARK, Del. — February 1, 2021 — Waste handling equipment manufacturer Lundberg Tech, Newark, Del., has introduced the WasteTech Automated Cleaning Efficiency (ACE) trim and label waste removal system. Based on the company’s signature WasteTech All-In-One trim removal system, the WasteTech ACE automatically captures edge trim, label matrix, die cuts, and other waste materials at the machine along with any dust generated, cuts it into confetti, collects it in a bulk bag for recycling or disposal, and cleans the airstream through a built-in filter. The self-cleaning filter system continuously removes any dust and other particulates from the pneumatic conveying airstream to eliminate the line stoppages often required to clear waste from other trim systems, and promote efficient, non-stop operation.

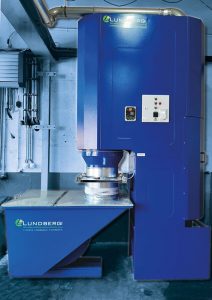

Developed for converters, label manufacturers, printers, textile manufacturers and others concerned with sanitary and/or automated production, the self-contained WasteTech ACE vacuum waste handling system excels at managing materials with a high degree of dust and fibers such as paper, fiberglass, foil, textiles, PET, and fiber-reinforced tapes. The proprietary, pre-engineered trim system integrates the Automatic Cleaning Efficiency filter with inlet tubes, pneumatic conveyor piping, granulator with silencer, ventilator with silencer, cyclone separator, and bag holder, plus a protective cabinet. A single unit may manage dust and waste from up to three different slitters, presses, die cutters, and other converting machines simultaneously.

Posted February 2, 2021

Source: Lundberg Tech