PFÄFFIKON, Switzerland — June 30, 2020 — The year 2020 is challenging the textile industry worldwide. Now more than ever, to remain at the forefront in this uncertain market environment, textile mills must be sure to operate with the highest efficiency while remaining flexible in terms of applications. At the same time, high quality is imperative in order to avoid second-choice production and material waste. Downtimes must be minimized, so rapid style and warp changes are mandatory. Suboptimal processing steps must be corrected because they can cause problems in the downstream weaving process. Stäubli, a global leading provider to the weaving industry, has a range of machinery that solves all these problems. The company’s state-of-the-art automation solutions for any woven application can be adapted to the specific needs of any mill and easily integrated into existing operations.

One step ahead of weaving and during the weaving stage itself, mills must master time-consuming process steps such as the drawing in and tying of warps. Stäubli enables mills to quicken the pace of such steps with its automation solutions which together ensure rapid preparation of high-quality warps. The recently launched TIEPRO tying machine sets a new standard for tying warps with or without a 1:1 lease. It features a new yarn separation system based on rotating spindle cones and is designed for universal use with standard warp yarns in any weaving mill [count range (tex)1×30 to 1×6.7]. TIEPRO boasts extremely high mechanical precision supported by high-performance digital technology, with unique control features such as Auto Reverse: When a separation error is detected (two or more ends separated together), the spindle cone reverses its rotation and retracts the separated yarns onto the cone. The machine repeats the separation process automatically, with no need for intervention by an operator. Once the single end has been properly separated, the yarn is automatically cut and a simple roll knot is tied. The length of the knot ends is freely adjustable; very short ends enable quick pulling-through on weaving machines. TIEPRO gives the mill immediate economic benefits such as savings of time and labor, lower operating costs, and lower maintenance costs due to simpler and easier maintenance requirements. The machine is ideally employed with Stäubli’s newly designed TPF tying frame. It can be placed very close to the warp beam and provides high tolerance regarding parallel alignment of the two yarn sheets, which makes stretching fast and easy and shortens the overall time required for warp changes.

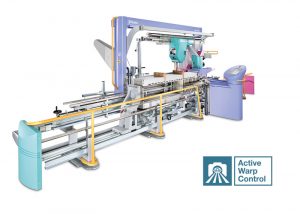

When it comes to drawing in warps, the SAFIR automatic drawing-in machines allow repeat-specific distribution of the warp yarns into the drop wires, healds, and reed in a single cycle. Highly flexible in terms of application and layout, SAFIR drawing-in machines can be integrated easily into existing material flows in mills of any size. These systems feature Stäubli’s unique state-of-the-art Active Warp Control (AWC) technology, and Initial Conditions Settings (ICS) for specific yarn properties are now available as well. These technologies allow mills to further enhance their quality and processing performance of multicolored warps with or without a lease. Yarn-repeat detection & management and S/Z detection & management are two AWC features prized by mills around the globe that require optimum drawing-in for their high-quality fabric production.

All Stäubli weaving preparation solutions share a key critical attribute: They support the production of perfect warps that enhance the downstream weaving process, which leads to greater volumes of first-quality output. Stäubli machinery optimizes production processes in the weaving mill, and the flexibility these solutions offer allows the machines to be adapted to the mill’s future needs. “Our global and local service teams, our agents, and our spare parts network are also there to support mills with personalized services,” said Fritz Legler, marketing and sales at Stäubli. “Our customers can achieve their goals more easily and master challenging situations.”

Posted June 30, 2020

Source: Stäubli