NORDHORN, Germany — February 2013 — 10 years ago Rosink successfully installed its first Air Quad

Web Splitting Unit, called RAQSU40 on to a Trützschler high production revolving flat card. This

started as a so called retrofitting project (textile machine modernization) and nowadays it is sold

as a working unit together with Rosink’s premium business partner Messrs. Trützschler, with sales

all over the world.

This development, from textile machinery specialist Rosink Maschinenfabrik, was, and still is

unique in the nonwoven hygienic industry.

The highly economical and short production process offers 4 ultra-light single slivers *

ranging between approx. 1,2 – 1,7 g/m each **; directly from the card without the need of a draw

frame. The 4 slivers are discharged by special ionization nozzles and coiled at high speeds up to

175 m/min! Various control systems ensure perfect sliver evenness.

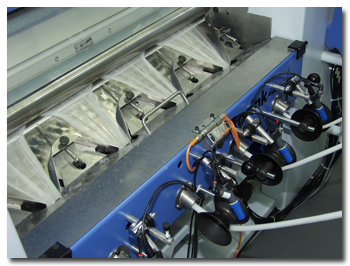

The special Rosink Quad Can Coiler, coils all 4 slivers smooth and precise into round

spinning cans 24″ x 48″. An automatic can doffing system, easily & quickly changes all 4 cans

at the same time. These cans of sliver can now go directly to your cotton swabs machine(s).

The above equipment “Made in Germany” includes the latest technology for trouble free &

safe running. Totally 74 installations are performing an excellent job throughout the world.

Rosink’s Web Splitting Unit

Besides this bleached cotton sliver production line, Rosink and Trützschler also mutually

sell, modern, high absorbent flat ribbon (tampon strip) production lines, for digital tampon

production.

Posted on February 19, 2013

Source: Rosink GmbH + Co. Machinenfabrik