F

or decades, Germany-based Trützschler GmbH & Co. KG has been known as a premium

supplier of spinning preparation machinery. In 2006, the company acquired Germany-based nonwovens

machinery manufacturer Fleissner GmbH. Since that time, the group of companies, which also includes

Germany-based Erko Trützschler GmbH, has become a serious supplier of complete nonwovens lines.

In September 2008 during an open-house event, Fleissner presented new machinery at its

technology center in Egelsbach. For nonwovens manufacturing, the following new products were the

focus of attention:

New cards: Three machines will support the existing Fleissner AquaJet Spunlace

lines. The previous card has been replaced by the newly developed EWK-413 card from sister company

Erko Trützschler. It is designed to process up to 400 kilograms per hour (kg/h) and is said to

deliver carded polyester/viscose as well as cotton products. This means that all main components of

the high-speed spunlace process for carded products can be supplied from companies in the

Trützschler organization: fiber opening and blending, and carding machines from Erko Trützschler;

and spunlace and drying from Fleissner.

The new EWK-413 card from Erko Trützschler is designed to deliver carded polyester/viscose

as well as cotton products.

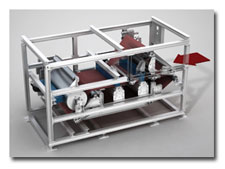

Small spunlace machine: The second new machine installed in the technology center

with the AquaJet line is the Trützschler TC 07-H card, which is said to have an improved machine

direction/cross direction ratio and together with the new Fleissner MiniJet spunlace machine offers

an economical solution. The machine is a tool to enter the spunlace nonwovens market, thanks to its

small size and production throughput. It mainly serves the needs not only of institutes and

companies conducting research and development, but also of producers in niche markets. The main

features of the quasi-plug-and-play machine are a working width of 50 or 100 centimeters (cm),

pressures of up to 400 bar and the possible integration of its specially designed foam padder into

the spunlace line. Fleissner decided to push the chemical bonding process, traditionally limited to

speeds of not more than 70 to 100 meters per minute (m/min), to line speeds of up to 200 m/min.

The new “MiniJet” spunlace machine is said to be an economical solution, thanks to its

small size and production throughput.

Belt oven technology: Also shown at the open house was Fleissner’s belt oven

technology for thermobonding of high-loft products. Webs from 200-cm up to 720-cm working width can

be processed. During the design phase, Fleissner paid special attention to providing highest energy

efficiency, lowest energy losses and easy access for maintenance. Working height and working width

adjustments are accomplished in a user-friendly way.

Fleissner’s belt oven technology is suitable for thermobonding high-loft nonwovens.

During the event at Fleissner,

Textile World

had the opportunity to interview Dr. Michael Schürenkrämer, Trützschler Group board member.

Schürenkrämer discussed Trützschler’s strategy and expectations with regard to its expansion into

the nonwovens market.

Fleissner Senior Sales Manager Peter Ziehl shows the high-loft product cured in the new

belt oven.

Independent Supplier

TW:

For decades, Trützschler has been one of the market leaders in spinning preparation. Now,

with the acquisition of Fleissner, the group is very active in nonwovens manufacturing. What were

the main reasons to expand the activities into this area?

Schürenkrämer: Trützschler already had delivered similar machinery for fiber

preparation in the nonwoven industry since the end of the 1960s. With the chute feeder for cards,

known by the name of Scanfeed, we even had solutions for special applications, which were not found

elsewhere on the market.

However, our product portfolio did not cover all requirements, even for fiber preparation,

and at the end of the day, we were merely subcontractors without any direct contact with the end

consumer in many cases. Furthermore, there was an ongoing consolidation process by our competitors.

For years, we were questioning ourselves whether to become totally independent or to abandon the

products. We preferred to do the first.

TW

: Do you have an official group name for the nonwovens activities?

Schürenkrämer: No, not yet, but we think that with Trützschler Nonwoven, our

activities might be clear enough for everybody involved in this industry.

TW

: Fleissner was sold by its founder to the Zimmer Group. Now, you have acquired Fleissner.

How did this happen?

Schürenkrämer: Well, we had heard that Zimmer wanted to sell Fleissner, and we

showed our interest. This was in 2006.

TW

: Why just Fleissner?

Schürenkrämer: Fleissner, coming from the dryer area, developed over decades a

very broad product program holding different bonding technologies, particularly spunlace. In a link

with our machinery and that of Erko Trützschler, we now can offer complete lines. Our interest in

Fleissner was obvious, and the chance came to us.

TW

: Are you satisfied with the business development since you have taken over Fleissner?

Schürenkrämer: To some extent, yes. For the nonwovens business, it represents our

cautious expectations, although we would have wanted it to be better. The man-made fiber area had

been very strong over the last years, and then it dropped. However, we already knew this situation

before the takeover.

TW

: Were your expectations fulfilled?

Schürenkrämer: Yes, with regard to the common further development of the product

program. The fine-tuning in the group gets gradually better, and we have already concluded the

first project with all three companies. We are quite happy with the result, taking into

consideration the short period of time.

Dr. Michael Schürenkrämer (left), a Trützschler Group board member, with Hans-Georg Buckel,

CEO, Fleissner GmbH

The Right Timing

TW

: You can now offer complete lines for nonwovens made of staple fibers from one source only.

Why did you wait with the presentation until this Fleissner event?

Schürenkrämer: An open house event offers different possibilities of presenting

the available know-how and products as well as demonstrating all kinds of solutions.

TW

: Why didn’t you do it at ITMA Asia?

Schürenkrämer: Now, we are able to present novelties that were not yet ready for

ITMA Asia.

TW

: What is the ratio in your group of traditional applications to nonwovens?

Schürenkrämer: The ratio is about 2.5 to 1.

TW

: How do you see Trützschler’s strengths in the nonwovens sector as a group and within the

individual companies?

Schürenkrämer: Total solutions are more attractive for many customers because of

the simplification of the project negotiations and implementations as well as warranty matters. For

this, however, it requires a wide supply range to be able to play an important role. We can claim

our role for many applications today. It’s nevertheless a usual practice for us to combine complete

lines on request of the customer and in cooperation with our competitors.

Furthermore, one of our strengths is our worldwide presence, which is already visible mostly

in the USA, because of the importance of the nonwovens business, followed by Brazil, but also India

and China, where we have our own production centers. In medium terms, all this will certainly bring

added value for our customers.

Erko Trützschler and Fleissner have their strengths in their products, the flexibility but

also in the respective services – each company in its own way, but this is certainly natural

because they have developed individually. The future lies in an even more intensive cooperation for

all involved companies.

TW

: What is the organization regarding service, representations and such? Are these the same

people who are also responsible in the area of the classic textile industry?

Schürenkrämer: Some representations were merged with the spinning, and some not.

We did what is best for the individual markets.

TW

: Is the turnover for your nonwovens activities increasing?

Schürenkrämer: Basically, yes, but the period of time for our extended activities

in this field is still too short to give a firm answer.

TW

: Were your turnover expectations fulfilled regarding nonwovens?

Schürenkrämer: Yes, with the exception of the mentioned situation of the man-made

fiber area. In my opinion, the combined activities of Trützschler and Erko, the extended product

line with the first needling machine from Erko, and the expectations of the customers that

Trützschler stands behind the two companies led to this pleasant situation.

TW:

Is Trützschler’s nonwovens group complete, or are you considering further acquisitions?

Schürenkrämer: The product program is already rather homogeneous; however, it

takes time for everything to accrete – grow organically – together. We are already on the right

track, but there is still some homework to be done.

The United States is the center of the Trützschler Group’s nonwovens activities. This was

underlined by the presence of staff from American Truetzschler, Inc. at Fleissner’s open house at

its technology center in Egelsbach, Germany. Pictured are CEO Kurt Scholler (far left) and Jim

Greene (far right), American Truetzschler; with Schürenkrämer; and Dr. Dieter Zenker, technical

director, Fleissner.

Market Situation

TW

: How do you see the current market for nonwovens?

Schürenkrämer: I see it with mixed emotions. In spinning, we have had a dramatic

drop since the last few months of 2007. This situation was primarily characterized by

overcapacities built up in the Far East. The situation for nonwovens is different because of the

more differentiated product spectrum. Applications in the automotive area are also showing a

decrease, but other areas are growing. At present, we have a lot of projects, which gives us an

affirmative thinking. However, the realization is still a long time coming.

TW

: How do you see the medium-term future for nonwovens?

Schürenkrämer: For years, the nonwovens business has shown growth rates above

average. There are great opportunities in this industry by using innovative approaches for new

applications and further growth. Creativity is needed to deal with the different applications and

to generate new products. As manufacturers of this machinery, we want to further support these

efforts.

Moreover, there are markets, like India, in which the nonwovens industry has not gained a

foothold at all yet. Much is said about nonwovens also from the spinning industry, but the

breakthrough hasn’t come yet. The search for the right products in an unknown territory is full of

risks, so one is understandably careful. On the other hand, there are already a number of

installations. All in all, we are convinced that we will have a further upswing if the general

conditions are positive.

November/December 2008