The North Face recently introduced two new fabric technologies — DOTKNIT™ and FUTUREFLEECE™ — designed to work and perform together, and as part of the Advanced Mountain Kit™ clothing layering system.

By Rachael S. Davis, Executive Editor

Never Stop Exploring™,” is a phrase well-known to out-door enthusiasts. The North Face, founded in the 1960s by avid climber Doug Tompkins, adopted this mantra in relation to its customers and their love for exploring outside. Beginning with backpacks, The North Face has innovated outdoor clothing and equipment for its customers to support their love of the great outdoors where environments can be hot and sunny, cold, wet or snowy, or variable.

The North Face mantra is also applicable to the company’s own drive to explore and innovate when it comes to its products. Over the decades, The North Face has expanded its product line to include clothing, shoes, bags, tents and other gear for hiking, camping, running, climbing and skiing. It was one of the first companies to create a backpack with a lightweight internal frame. The North Face also was an early adopter of Gore-Tex™ technologies in the 1970s. Today, the company has a full suite of waterproof, breath-able product offerings that includes FUTURELIGHT™ and DryVent™ technologies; as well as Ventrix™, an insulation technology that keeps your body warm without overheating, among other The North Face branded innovations.

Responsible Product Choices

The company also maintains a focus on responsible products and circular design principles. By 2025, The North Face aims to have “100 percent of our leading apparel fabrics originate from recycled, responsibly sourced renewable or regeneratively grown sources.” It focuses on using recycled, biobased and regeneratively grown materials, as well as responsibly sourced down. The North Face also eliminated per- and polyfluoroalkyl substances (PFAS) chemicals from the manufacturing of its consumer products in 2024.

“In 2024, more than 90 percent of our polyester was recycled,” said Carol Shu, senior manager, Global Sustainability. “Additionally, we’re utilizing circular design principles across key product lines so that once those products reach the end of their usable life span, they can be properly disposed of and recycled or utilized to make future products. We’ll continue to make great strides in 2025 to inch closer to our end goal.”

Technology Development

The brand’s suppliers are instrumental in helping The North Face bring technologies to market, but innovations are tailored for The North Face consumers internally. According to Forrest Cannon, Materials manager, Innovation Development, the company focuses on a three-step process for technology development:

- Research and validation;

- True technology development; and

- Deployment of technology.

“This approach allows our team to thoroughly understand the key characteristics of a technology influencing performance, to develop it into essential styles and applications that best serve our consumers, and to strategically incorporate the technology into our product line in a meaningful way,” Cannon said.

“Our process always begins with a problem to solve,” said Kyle Parker, product director, Apparel Innovation. “The team constantly meets with athletes, consumers and internal teams who provide inspiration in many ways — a new project in the mountains, a ‘perfect layer’ solution that may not exist, or even a simple idea about the way they’d like a material or garment to feel or per-form. All of these serve as inputs that we brainstorm and consider in our design process, looking beyond existing solutions from our supply chain for inspiration for our starting point.”

New Introductions

DOTKNIT™ and FUTUREFLEECE™ are two new fabric innovations recently introduced to the market by The North Face.

“DotKnit technology was born as a solution for managing moisture in the mountains,” Parker said. “In high alpine environments, moisture trapped next to the skin can cause hypothermia. As a result, athletes will moderate their exertion to manage their sweat rate as a function of safety.”

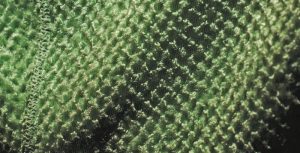

DotKnit material is a lightweight, double-knit fabric featuring a textured dot pattern. The fabric was designed to pull moisture from the skin and transport it to the outside of the fabric away from the body to reduce the risk of hypothermia. The trick is in the yarn choices. Two polyester yarns are used — the inner yarn is modified to be hydrophobic, and the outer yarn is hydrophilic. The yarns plus the engineered “holes” in the knit construction create a conduit to move moisture from the skin and through the fabric. The knit construction also contributes to increased air-flow to help with sweat evaporation.

DotKnit garments — mostly tees and tops —are designed as a first layer to be worn directly next to the skin under a midlayer or an insulating layer.

DotKnit fabric’s construction focuses on moving the moisture directionally away from the body according to Cannon. “In a DotKnit fabric, the majority of evaporative cooling will occur away from the skin, which allows our athletes and consumers to stay drier and warmer in high aerobic, cold weather activities,” Cannon said.

Internal testing laboratories at The North Face test for one-way moisture transport, evaporative resistance and air permeability to ensure the fabric meets the needed moisture and thermal benefits required for the application.

“A key point of difference between DotKnit technology and other ‘standard’ baselayers is that it actively moves moisture from the body,” Cannon noted. “Standard wicking tests only quantify how far the moisture has spread across a fabric, but not directionally from one side to another, which we test for with DotKnit fabric. Additionally, we have our world-class athletes testing our materials through a variety of climates and activities. They do a great job making sure we can stand behind our motto of ‘Athlete-Tested, Expedition-Proven!’”

DotKnit fabrics, used broadly across the product line, form part of The North Face’s Advanced Mountain Kit™, its alpine climbing system comprised of five technologies designed for layering. The North Face plans new silhouettes and material variations for several sea-sons to come, according to Parker.

FUTUREFLEECE™

FutureFleece fabric is another new technology that is part of the Advanced Mountain Kit. “Designed to be worn as a first layer over a baselayer, like DotKnit garments, or as a next-to-skin solution in cold conditions, FutureFleece fabric efficiently regulates the microclimate of the wearer,” Parker said about this fabric innovation.

The knit fabric features a grid pattern alternating between areas of looped yarns and flat knit areas. The pattern with high/low areas traps heat within the non-looped areas, increasing warmth and helping to regulate body temperature all in a fabric with an optimized warmth-to-weight ratio. The full-loop construction also results in a soft next-to-skin feel.

“FutureFleece fabric is a very unique knit construction that does not require brushing like traditional fleece products,” Cannon said. “Our engineers and designers are always thinking about how to improve the performance of our technologies. In FutureFleece fabric, the incremental pile against the skin allows us to reduce weight and increase air permeability on a highly insulative fabric.”

FutureFleece technology also utilizes an octagonal-shaped “octa-yarn,” which is instrumental in the fabric’s performance, according to Cannon. “This highly engineered fiber features both a hollow core and an eight-fin surface structure,” Cannon explained. “The hollow core component helps boost the warmth within the fiber, while the eight-fin structure creates additional insulative air pockets within the yarn and further boosts the warmth without an increase in weight.”

To test the thermal resistance of the fabric, The North Face team used its internal lab’s Sweating Guarded hot plate. “FutureFleece fabric has shown to have the highest warmth-to-weight ratio out of the fabrics we’ve tested,” Cannon shared.

This warmth-to-weight property of FutureFleece fabric makes it the athlete’s most used layer across the entire range of activities and geographies, according to Parker. The fabric currently is featured in several silhouettes and material weights across The North Face’s Summit Series, from quarter zip crew neck styles to full-zip hoodies. “This offering covers the needs across a wide variety of activity use cases,” Parker said. “We will continue to expand FutureFleece fabrics into Hike and Trail run in the seasons to come.”

Complete Clothing System

DotKnit and FutureFleece technologies pair well together and have a purpose within The North Face’s Advanced Mountain Kit layering system. “When DotKnit fabric is combined with FutureFleece fabric and Futurelight — our most advanced, breathable waterproof solution —sweat is able to move and evaporate efficiently through the entire clothing system,” Parker shared.

impact.

Sustainability At The Forefront

As The North Face was developing the DotKnit and FutureFleece fabrics, the company’s sustainability goals and responsible materials choices were fully considered. “DotKnit fabric is made with recycled polyester and the garments meets our EXPLORATION WITHOUT COMPROMISE™ criteria,” Senior Global Sustainability Manager Shu reported. “FutureFleece fabric currently has 37-percent recycled content and hasn’t reached the Exploration Without Compromise criteria; however, in a future season, this fabric will be converted to 100-percent recycled con-tent and the garments will meet Exploration Without Compromise.”

As The North Face looks to the future, its commitment to innovation, sustainability, and performance remains unwavering. By continually pushing the boundaries of material technology and embracing circular design principles, the company not only supports outdoor enthusiasts in their adventures but also protects the environments they cherish. With a legacy rooted in exploration and a vision focused on responsible growth, The North Face is poised to lead the way in creating products that inspire, perform, and preserve for generations to come.

2025 Quarterly Issue I