At ITMA 2023, companies presented their novel developments that are assisting the fashion industry in providing customers with ergonomic apparel.

By Reza Kamali Miab

Ergonomic apparel seeks to optimize comfort, functionality and efficiency for the wearer. Customers can benefit from ergonomic garments, not just from increased comfort, but also in injury prevention. Safety is intertwined with physical ergonomics topics. Effective ergonomic design can optimize pressure distribution, and reduce impact force and discomfort. Ergonomic garments provide users with advantages such as positive impacts on human performance and health, mental workload, decision-making, skilled performance, human reliability, and productivity1.

There are many parameters including proper fit, pressure and fabric tension on the skin, and friction between fabric surface and the skin that should be met in well-designed ergonomic, and comfortable apparel. Implementation and development of ergonomic parameters in textile products requires developments on the production lines. Many enterprises work on providing textile firms with equipment which can assist them to meet ergonomic garments requirements in their production. Nowadays, comfort and fit are top priorities for individuals when selecting apparel.2,3,4 Many parameters should be considered in designing ergonomic garments. Finding the proper fit plays an important role in this matter. At ITMA 2023 in Milan, Italy, several companies presented products to facilitate the production of well-fitting and ergonomic clothing. This paper introduces some of them and their developments in facilitating the manufacturing of ergonomic apparel.

Customization With 3D Body Scanning

Over the past two decades, some studies have been conducted regarding the use of 3D body scanning techniques to help with fit in apparel production.5,6,7 This technology has aided the textile industry in various areas from the classification of body shapes to finding the alterations of body dimensions in different postures.8,9

Customized Avatars

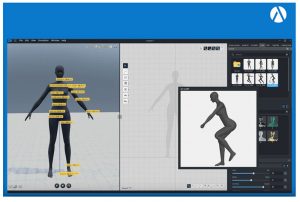

Pattern-making is one of the earliest steps in apparel production. Nowadays, many fashion designers benefit from computer-aided design (CAD) software when developing new apparel. To design fit garments, designers need a 3D avatar with a great similarity to real body shapes. AUDACES is an Italian-Brazilian company that has considered this issue when developing products. Audaces has been active in different areas of the fashion industry for more than three decades offering a pattern plotter, fabric layers spreader, pattern conveyor cutter, and a wide range of software that are requirements of all garment, fashion, technical clothing and upholstery productions, among other technologies.

Before garment production, 3D visualization software provides the ability to check garments on 3D avatars. Besides the aesthetic aspect, comfort and fit parameters play an important role in pattern making. Realistic avatars provide a real perception of fit and comfort for designers in pre-production steps. Audaces offers a 3D visualization software called AUDACES 3D. The company has equipped its software with the ability to import the client’s 3D body scanning photographs as a customized avatar, which allows the designer to understand how the garment will look on the body in reality. AUDACES also has added the capability to import customized avatars by using 3D body scanning techniques. Customized avatars represent the client’s body shapes and designers can adjust the patterns on the realistic body shape. To produce garments and gear for users with unique body types, including individuals with some diseases and disabilities, this technique becomes more important and helpful. This technique can provide disabled individuals with their desired fit and comfortable garments by aiming at measuring accurate and precise body sizes and simulating the morphological shape of clients with atypical skeletal structures and physical deformations such as scoliosis patients10. As a result, the designer is able to check the tension on the avatar and make adjustments or redesign the clothing patterns — if they are needed — to meet desired fit. Furthermore, designers can drape fabrics onto the mannequin to simulate the natural fall and behavior of the fabric on the human body. This enables them to visualize and adjust the pattern’s shape, seams, and proportions for optimal fit and aesthetics. Companies can reduce their physical prototype, consequently, this technology helps in sustainably saving time and resources, and also it positively impacts customer satisfaction levels.

Classified Clothing Patterns

Australia-based Pattern Room presented a comprehensive clothing patterns database that is a game changer for designers and garments at ITMA 2023.

The main aim of this company is to provide a comfortable fit for clients. Experts in this company believe that fit is not size. Individuals, in addition to the right size, should consider the fit in garments to feel comfortable. Pattern Room describes fit using six different categories including compression, tight, slim, regular, loose, and oversized. Designers should consider what the client is looking for to cover the blanks to fit. To benefit from the Pattern Room database, the type of garment should first be selected. Customers can easily find the desired styles in the next step. In the final step, clients choose sizing and then patterns are quickly ready to purchase.

Pattern Room offers a comprehensive database aimed at resolving fit issues encountered by garment manufacturers and tailors. Designers can identify perfectly fitting garments for customers, which serve as representatives of the desired fit and size. The company utilizes a 3D body scanning technique to collect diverse body shapes, creating an optimized dimension database. Designers can then access clothing patterns which are classified by gender and body styles in this database for subsequent garments, ensuring consistent fit and customer satisfaction. This approach minimizes product returns and refund requests, leading to happier customers and potential positive reviews, ultimately contributing to increased profitability. Through the usage of this dataset, grading processes could become much easier and quicker for apparel designers and manufacturers. The Pattern Room’s garment patterns, developed through 3D visualization, are cost-effective, increase productivity, and reduce design process time, offering sustainable solutions for the fashion industry.

Customized Mannequins

Italy-based Cad Modelling S.r.l. targets fit, safe and ergonomic apparel. It has developed its tailor mannequin concept to evolve fit in the apparel industry. At the same time, it has developed technology in mannequin production that saves time and resources in a sustainable way. The company presented a technique to create customized mannequins during ITMA. The technology uses 3D body scanning technology to scan individuals’ whole bodies or parts of their bodies. The process captures the shape and dimensions of the person’s body and creates a digital 3D model. This photo capturing is performed by 3D scanned sensors and may be from the full body or only of a specific body part such as the hand, head or foot to produce mannequins that can be used to design customized and well-fitting gloves, helmets, footwear or other specific gear. The scanned photos are exported in “.stl” or “.obj” files for further processes. Scanning has to be done in static status and the quality of sensors used in the body scanning directly impacts the quality of the results. It is clear that to achieve the best results, higher quality scanner sensors should be used. The exported files obviously can be used as customized avatars for CAD purposes in 3D visualization software.

For the further step of production, CAD Modelling utilizes the Computer Numerical Control (CNC) technology which is automated machinery controlled by computer programs to precisely cut, shape, and carve fiberglass. They selected fiberglass as a substance because it is strong and light enough to be a proper material to make durable and easy-to-use mannequins for seamsters. CAD Modelling exhibits how CNC can be valuable and efficient for the fashion industry. First of all, 3D body scan files are imported into 3D modeling software to refine and optimize the model. During this step, adjustments can be made and imperfections are cleaned up, if needed, then digital models for CNC processing are prepared. The company believes that CNC is the best option to make mannequins with the highest level of accuracy and similarity with the original models. Utilization of the CNC technique in the fashion industry is very rare and it is hard to find examples of such use. Tailors, seamsters and designers can visualize how the finished garment will look on a body by seeing it on a mannequin that closely represents their measurements and proportions. CAD Modelling creatively not only provides comfortable, well-fitting, and well-designed garments, but also helps the polluting fashion and textile industry to move toward sustainability.

Pressure Measuring Device

As mentioned previously, fit is one of the most important parameters of ergonomic apparel. Many companies have created clothing patterns, avatars, and mannequins that are precisely similar to real body shapes to provide designers with the tools to design beautifully fit garments for their clients.

But to test and find the fit issues, monitoring the pressure of garments, gear, or footwear on the skin is necessary. Manufacturers need equipment to measure the pressure to find peak pressure and evaluate the level of pressure that is safe and practical for users. To meet standard levels of pressure and reduce the risk of injuries to end users, clothing patterns may need to be modified or redesigned. There are many different types of pressure sensors, but they must be feasible to be embedded and fixed inbetween the internal layer of the garment and the user’s skin.

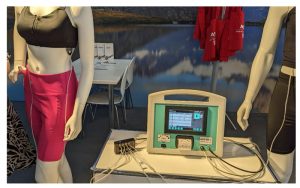

At ITMA 2023, Switzerland-based Swisslastic AG presented an apparatus named the Multi Pressure Tester. This device is a multipoint probe system offered in two models including MPT-4 and MPT-7, which are equipped with four and seven sensors respectively. The sensors can be applied on most parts of the body including the foot, knee, elbow, abdomen and lumbar. The tester is compatible with a wide range of garments such as socks, underwear, sportswear, sports bra and shapewear, among other garments.

The device was demonstrated in the company’s booth during ITMA 2023. At first, the operator applies the probes to the skin, then puts the garment on, and finally connects the probes to the multipoint hub to start measuring pressure. These sensors are also able to be installed on mannequins. Swisslastic mentioned that portability and user-friendliness are the most noticeable and considerable advantages of this device. The range of pressure measurement by this equipment is 5 to 70 mmHg. The probes are designed with a 50 millimeter diameter and are flat, so they do not overstretch the garment or bother users during testing. At the end of the test, the results are shown on the screen of the device and can be transferred to the computer for further analysis. Multi Pressure Tester is a significant technology to find the right amount of pressure for designing ergonomic apparel and plays an important role in functional garments like sportswear, military clothing, firefighters’ turnout suits, and protective hospital clothing.

Utilization of pressure sensors in the textile industry to design ergonomic garments is a growing technique and the demands on it from the market are rising in comparison with the past. As a proof of concept, Iran-based MR-KNIT Group — a producer of yarn tension meters — considering the increasing demand for the pressure meter of garments and has started to make pressure sensors, which demonstrates how much demand is increasing for this technology.

Conclusion

Since the demand for comfortable and well-fitting apparel is rising among consumers, designing and producing clothing that meets ergonomic parameters plays an important role in achieving market share. The tendency of individuals to wear comfortable garments is rising. It is the fashion and textile industries’ responsibility to design and produce ergonomic clothing to meet this demand. Fit is one of the most significant parameters of ergonomics and should be considered by designers. The textile and fashion industry by manufacturing ergonomic garments is not only able to improve the level of client satisfaction but also moves towards sustainability by saving time and resources, increasing the lifetime of garments, and reduction in return rates. This enhances customer satisfaction, consequently, it could reduce the chances of returns and waste. The high return rate negatively impacts environmental sustainability and increases greenhouse gas emissions11.

At ITMA 2023, companies presented their novel developments that are assisting the fashion industry in providing customers with ergonomic apparel. By benefiting from the 3D scanning technology, CAD Modelling creates customized mannequins, the Pattern Room has prepared a wide range of well-fitting clothing patterns for various body shapes and AUDACES 3D can import customized avatars for each client. As a representative of Swisslastic mentioned, the probes of its multi pressure device can be applied to the body as well as on mannequins. Combining this technology with customized mannequins can have significant effects on easing the production of ergonomic apparel. All these products provide garment manufacturers with developed requirements to produce more comfortable and fit garments for customers. As a result of ergonomic garment production, the textile and fashion industry become more sustainable and environmentally friendly due to the reduction in resource consumption and waste, saving time, and increasing the level of consumer satisfaction.

References

- McCauley, P., Ergonomics: foundational principles, applications, and technologies, Boca Raton, FL: CRC Press, (2012)

- Stephen Parker, R., Hermans, C.M. and Schaefer, A.D. (2004), “Fashion consciousness of Chinese, Japanese and American teenagers”, Journal of Fashion Marketing and Management, Vol. 8 No. 2, pp. 176-186. https://doi.org/10.1108/13612020410537870

- Chowdhury, T. A., & Akter, T. (2018). Fashion attributes preferred by young Bangladeshi consumers while buying casual clothes: A multi-dimensional approach. Journal of Fashion Marketing and Management: An International Journal. https://doi.org/10.1108/JFMM-02-2018-0018

- Abdolmaleki, H., Mirzazadeh, Z. S., & Ghahfarokhhi, E. A. (2018). Identify and prioritise factors affecting sports consumer behaviour in Iran. International Journal of Sport Management and Marketing, 18(1-2), 42-62. https://doi.org/10.1504/IJSMM.2018.091331

- Istook, C. L., & Hwang, S. J. (2001). 3D body scanning systems with application to the apparel industry. Journal of Fashion Marketing and Management: An International Journal, 5(2), 120-132

- West, A., & GABEL, A. (2014, October). 3D Color Body Scanning for Improved Sample Fit and Accuracy in Garment Design. In 5th International Conference on 3D Body Scanning Technologies, Lugano, Switzerland (pp. 21-22)

- Irzmańska, E., & Okrasa, M. (2018). Evaluation of protective footwear fit for older workers (60+): a case study using 3D scanning technique. International Journal of Industrial Ergonomics, 67, 27-31. https://doi.org/10.1016/j.ergon.2018.04.001

- Devarajan, P., & Istook, C. L. (2004). Validation of female figure identification technique (FFIT) for apparel software. Journal of Textile and Apparel, Technology and Management, 4(1), 1-23.

- Lee, W., Yang, X., Jung, H., You, H., Goto, L., Molenbroek, J. F., & Goossens, R. H. (2016). Application of massive 3D head and facial scan datasets in ergonomic head-product design. International Journal of the Digital Human, 1(4), 344-360. https://doi.org/10.1504/IJDH.2016.084592

- Hong, Y., Zeng, X., Bruniaux, P., & Liu, K. (2017). Interactive virtual try-on based three-dimensional garment block design for disabled people of scoliosis type. Textile Research Journal, 87(10), 1261-1274. https://doi.org/10.1177/0040517516651105

- Bozzi, C., Neves, M., & Mont’Alvão, C. (2022). Fashion E-Tail and the Impact of Returns: Mapping Processes and the Consumer Journey towards More Sustainable Practices. Sustainability, 14(9), 5328. https://doi.org/10.3390/su14095328

Editor’s Note: Reza Kamali Miab is a Ph.D. student at the NC State Wilson College of Textiles, Raleigh, N.C. His major is Textile Technology Management with a minor in Industrial Systems and Engineering. His area of research is in clothing comfort and ergonomics.

April 19, 2024