Reshaping The Apparel Industry

Digital imaging, electronic color matching are in the spotlight at high-tech show.Bobbin

Americas 2000, held September 13-15 at the Georgia World Congress Center, Atlanta, focused on mass

customization and digital tech-nologies that offer the sewn products industry the opportunity to

reshape its business horizon. In addition, the show presented a host of network solutions, new

product premieres and educational events.A new feature of the exposition, according to Margaret

Crow, Bobbin Americas 2000 director of marketing, was The Digital Zone, with exhibits and

interactive digital production displays. The show also featured a Production Sourcing Expo, a

Fabric Sourcing Expo and a complete seminar program.

The shows Digital Zone, which was created and co-produced by the Cary, N.C.-based

TextileandClothing Technology Corp. ([TC]2), Bobbin Americas sponsor Miller Freeman, and 15

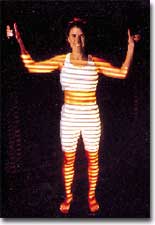

high-technology exhibitors, offered a look into the future of the sewn products industry.[TC]2, a

not-for-profit organi-zation supporting the apparel industry, announced the formation of ImageTwin

Inc., a joint venture with Truefinds.com Inc., a preferred stock subsidiary of Konover Property

Trust, Cary, N.C. The venture is the first Web-enabled 3-D digital body-scanning and measurement

system. The technology is designed to provide a definitive solution for accurate apparel sizing for

online, catalog and bricks-and-mortar shopping.ImageTwin is the culmination of a nine-year

development effort that resulted in a safe, white-light scanning process that generates extremely

accurate measurements in less than 12 seconds. ImageTwins in-store scanning station instantly

captures more than 200,000 data points of an individuals image, compiling a full 3-D representation

of his or her body. Proprietary software, in turn, automatically extracts dozens of sizing

measurements that can be used to create a perfect custom-fit garment or predict the appropriate

size of existing ready-to-wear clothing.The ImageTwin is part of [TC]2s overall strategy in

developing a more efficient apparel supply chain by increasing forecasting accuracy and reducing

merchandise returns, said Peter N. Butenhoff, president, [TC]2. [TC]2 also presented interactive

exhibits, demonstrating the power of integrated digital technologies in the sewn products supply

chain. There was also an opportunity to take a look at mass customization and virtual try-ons, as

well as digital fabric printing, all of which could become more and more a part of everyday

life.Customized Garments

At Gerber Technology, Tolland, Conn., also in The Digital Zone, Deborah Marconi, manager,

public relations, pointed to several products that will help manufacturers create customized

garments quickly.The individuals preferences as to style, color, size and fit are translated into a

unique garment. With such tools, manufacturers receive an order, generate patterns and markers, and

can digitally present the final product in minutes. Also, these tools eliminate the use of paper,

reduce the potential for inaccuracies, decrease turnaround times, and allow manufacturers to

realize greater profitability and repeat business.With Gerbers Made-to-Measure (M-T-M) software, a

garment is custom-made to the buyers preference. Manufacturers receive orders automatically through

mainframe, modem or internet connection, and M-T-M then creates the patterns and automatically

makes a marker. This facilitates the all-important quick turnaround.In addition, Marconi said

Gerbers new, automated plaid/stripe matching system, InVision, delivers thread-to-thread accuracy

and is now available from Gerber Technologies on its GTxL GERBERcutter. The units multitasking

operating system carries out matching and cutting operations simultaneously for optimum

productivity in the cutting room.InVision improves productivity by completely automating the

matching process, thus removing errors. It makes matching and cutting plaid and stripe fabrics as

easy as cutting solid fabrics, eliminating errors when using manual or semi-automated matching

processes.InVision contains an advanced camera and optics system to enable the operator to zoom in

on critical areas for added precision. In addition, its state-of-the-art lighting system and

imaging techniques achieve precise matching even through a plastic overlay. The system also cuts as

it matches.E-Business Solutions

Paris-based Lectra Systs offered its new e-business product that combines CAD/CAM, virtual

reality and the Internet to enable customers to create, manufacture and sell their products in a

fully electronic way, capitalizing on both their existing organization and new technologies.The

LectraOnline portal, launched in October, provides customers with online professional services and

facilitates secure data exchange between principals, subcontractors, textile companies and

retailers.Also on exhibit was the Lectra FitNet, which creates a virtual 3-D double of a person in

20 seconds thanks to its partnership with Tecmath, a German company specializing in computer

simulation of the human body. One can dress the 3-D double with a garment that is the right size

and personalized to suit the persons tastes, cut the garment in less than four minutes, and

manufacture it in under four hours.This procedure, with Lectras new 3-D virtual design

technologies, enables mastery of the way fabric behaves and faithful reproduction of its

draping.The LectraOnline portal will allow Lectra group customers to create garments automatically

in 3-D on the Web using existing models. During 2001, websurfers will be able to try clothes on

their own virtual mannequin, choose the right size or have the clothes altered to suit measurements

and styles.Lectra Systs is also involved in CAD/CAM systems for the upholstery industry, which is

being revolutionized by the new all digital model of design, as well as manufacturing solutions

that guarantee improved cut quality to the millimeter.The company incorporates all the links in the

chain with global, integrated CAD/CAM solutions that cover the whole textile process, from basic

materials to finished product in the upholstery industry.These solutions take in the full cycle,

starting from the virtual design of yarn and fabric and continuing through 3-D, CAD systems and

collection management; digital fabric printing for prototypes; automated fabric and leather

cutting; computerized technical data exchange; right up to virtual merchandising.Maureen Kelly,

marketing manager, Datacolor International, Lawrenceville, N.J., said that though everyone is

talking about communicating color, Datacolor is delivering it. With the companys Colorite program,

one can communicate exact colors electronically. Everything is calibrated, including print, for

true-color output. Kelly said Datacolors software instruments and services are designed to save

time throughout the entire color development process.The Colorite Studios offer an optimal viewing

area for the Colorite program, which is said to be an integral part of a revolutionary new Color

Information Management System (CIMS). CIMS is Datacolors complete computerized environment for

color measuring, matching, quality control and communication.Thus, designers, colorant suppliers,

and production staff can see and communicate color digitally, eliminating the need to mail color

samples between locations and cutting the cost of samples and development time in half. These

advantages allow companies to move rapidly with production, delivering products with savings in

administrative costs.

Editor’s Note: Diane and Bob Wanger are freelance writers based in Nashua, N.H.

November 2000