Successful CAMX aided by location near composite and textile manufacturers based in the southeast.

Successful CAMX aided by location near composite and textile manufacturers based in the southeast.

By Jim Kaufmann, Contributing Editor

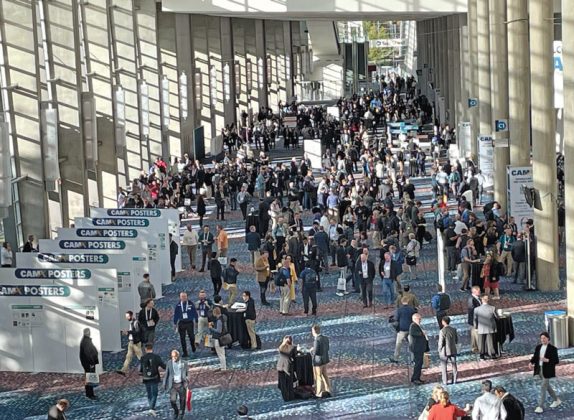

As the composites industry in North America continues to grow and blossom into newer and more creative applications, so too does CAMX, the Composites and Advanced Materials Expo. This year’s edition of CAMX was held for the first time at the World Congress Center in Atlanta, and by all accounts it was another successful event. Joan Higginbotham, a retired NASA astronaut who now is president of Joan Higginbotham Ad Astra LLC — an aerospace consulting firm — was the keynote speaker. She discussed her rewarding careers and her perseverance in becoming a rocket scientist and astronaut, which led to becoming a crew member of a 2006 space shuttle Discovery mission to the international space station. Upon returning to terra firma and after her time with NASA ended, Higginbotham embarked on a career focused on driving social impact and eventually became an aerospace consultant.

During the show, CAMX Award winners were announced with the University of Maine accepting the Combined Strength Award for its BioHome3D — a unique biobased, fully 3D-printed and fully recyclable house that included a novel printing twist. To provide better integration of design aspects, the university created a patented process for large scale 3D-printing at a 45-degree angle. A representative segment of the printed house structure was available on the show floor and drew a lot of attention during the expo.

Strongwell, Bristol, Va., received the CAMX Unsurpassed Innovation award for its 200-foot all pultruded structure, which is part of a 40-year infrastructure initiative to make wireless energy transmission more feasible. Bespoke tooling was designed and used to pultrude the individual shapes necessary to create the structure.

As always, the conference segment provided a variety of session topics ranging from “AI Machine Learning in Composites” to “Avoiding ‘Greenwashing’ Claims” and more. Poster sessions also returned and provided additional opportunities to expand one’s knowledge of the advancements in composites. However, as typically is the case, most were attracted to the activities found on the show floor where a growing number of booths and exhibiting companies displayed their wares demonstrating once again how the composites industry endeavors to keep moving forward.

The expo floor felt bigger than in past years, but those wandering the hall were able to see and speak with a bevy of industry experts from up and down the supply chain. Composites One and the Closed Mold Alliance, as has become a welcomed tradition, again used a portion of the expo floor to demonstrate molding techniques and advanced processes. CAMX also offered the CAMX Theater to provide assorted additional education opportunities to those on the expo floor. However, the real attractions were the various exhibitor booths, which held the treasures most attendees might have been searching for. A few treasures or at least items of interest included:

- 3D printing technologies, featured by several different exhibitors, continue to evolve and grow as a processing system into new and more complex shapes, configurations and applications.

- WEAV3D, Norcross, Ga., highlighted its woven composite lattice reinforcement structure, “Rebar for Plastics” that incorporates spread tow tapes. The lattice framework of the structure allows WEAV3D to locally tune performance characteristics to meet molded component needs, reducing component costs to targeted transportation and industrial applications.

- Innegra Technologies, Colfax, N. C., recently acquired by and now part of the Quantum Group, showed the versatility of its Innegra S fiber — a high modulus polyolefin multifilament yarn — in different textile and composite applications. It can be used in con-cert with other high-performance fibers such as carbon or glass, to improve toughness, durability and vibration dampening of molded parts, while also improving overall part cost and reducing weight.

- Several booths featured composite parts produced with recycled content, including recycled carbon and glass. Also, work continues in developing green composites, some of which could be found within the innovation displays.

- Also of interest in the innovation displays was a new composite based vertical axis wind turbine system from Be-Wind, Melbourne, Fla., that has a much smaller profile and cost than current wind turbine systems.

- IFC Mercantile LLC, Warren, N. J., promoted a modified acrylic — not modacrylic — staple fiber with inherent flame-retardant properties that does not melt or drip. It is intended for flame retardant applications including protective apparel, higher temperature filtration, industrial and technical applications.

Attendee and final exhibitor numbers were not available as of TW’s press time, but the general consensus of participants and exhibitors surveyed was that this year’s CAMX was another success. And Atlanta, though colder and windier than many expected, proved again to be a viable location for such an event given its proximity to the southeast’s textile and composite manufacturers. The 2024 CAMX Expo will be held September 9-12, 2024, in San Diego, Calif. Hope to see you there!

November/December 2023