While ITMA remains an event with limited composites offerings, plenty of composite related innovations were to be found at ITMA 2023.

By Prateeti Ugale

The 19th international textile machinery show, ITMA 2023 was recently held in Milan. The “Olympics” of textile machinery exhibitions held every four years, has a 73-year history of displaying the latest technology for every single work process of garment making and textiles. Out of the many products specialized in various areas, this article focuses on the latest and existing machinery for textile reinforcement structures, composite processing machinery, and accessories for the same.

A composite is made up of at least two components that possess significantly different physical and chemical properties which when combined forms a material that possesses advantageous properties of all the base components. In textile reinforced composite, the two components are matrix, which is a polymeric bonding component and textile, which is a reinforcement. The resultant composite benefits from tensile strength of the textile reinforcement and compressive strength of the matrix. Common fibers used are carbon, glass, basalt, aramid, or natural fibers to provide strength to the material whereas, matrix resins include materials like epoxy, polyurethane (PU) and others which function as glue to hold the reinforcement in place1. Braiding, nonwovens, knitting, weaving production techniques can be used to obtain reinforcement architecture. Composites have infinite applications including automotive, sports, aerospace, medicine, construction, and many others. The composite manufacturing process usually includes:

• prepreg — fiber architecture achieved through careful placement of fibers also called tape laying;

• impregnation — fibers and resins are comingled to form a composite; and

• consolidation — intimate contact is made between layers of fibers or lamina.

Composites can also use fillers, additives, and surface finish coatings depending on end-use applications. Lamination technique or process is another class of composite which involves manufacturing a material with multiple layers to achieve end-use properties like appearance and strength.

Technical Textile Reinforcement Structures

Braided Reinforcement Structures — Braided composites are at the forefront of the composite market due to their structural integrity and cost efficiency. The France-based Interreg North-West Europe (NWE) Program supported COBRACOMP project aims to develop, test, and validate a new automated textile braiding process to produce preforms for composite materials reinforcement. The organization displayed a section of its braider at ITMA. Higher mechanical performance is achieved with the innovative multilayer 3D axial braid assembly with more axial yarn, fiber fraction, and homogeneity. Composites expert Georges Cahuzac invented new architecture that has no gaps between unidirectional (UD) fibers, a bias to UD ratio of 5:4 equal to 80 per-cent and introduces four UD sections per layer. Front crash cone is an application that illustrates that this braid can absorb lots of energy due to the presence of UD yarns which help resist crack propagation.

Zhejiang Benfa Technology Co. Ltd., China, showed a hose braiding machine at its stand. The braids produced from this braider are used as high-pressure wire hoses, Teflon hose, high pressure rubber hose and car air-conditioning hose, among other applications. Its machinery can braid using stainless steel and aluminum wire as well as nylon, polyethylene and composite yarn material.

Germany-based HERZOG GmbH displayed SE 1/32-432 and SE 1/32-266 rope braiding machines. Its GF 1/32-120 glass fiber braiding machine along with the take-up is used for producing fiberglass sleeving and for overbraiding hoses with fiberglass.

Nonwoven Reinforcement Structures — Germany-based AUTEFA Solutions converts carbon fiber waste by recycling carbon fibers to carbon fiber nonwovens. If the waste is resin-free it can be directly processed on AUTEFA machinery; if not, the resin needs to be removed using pyrolysis. The Aerodynamic Web forming Machine Airlay K 12 can produce a nonwoven with isotropic fiber orientation and medium fiber separation. Autefa Solutions’ Carbon Card can produce incredibly good fiber separation with UD orientation. The fiber orientation, surface weight and width of the nonwoven can be adjusted using Crosslapper TOPLINER in combination with the card. Its Needle Loom Stylus can process 100-percent carbon fibers and enable mechanical web bonding. By adding a thermoplastic, thermal bonded nonwovens can be produced using Thermobonding Oven HiPerTherm. Autefa is the key supplier for carded-crosslapped needlepunch lines, aerodynamic web forming technology, thermobonding lines and spunlace lines.

Germany-based Dilo Group demonstrated brand new MicroPunch technology as alternative to hydroentangling. This is a “green” needling technology for lightweight nonwovens right from bale opening to final winding step. The technology is classified green because the trimmed material can be recycled within the process therefore there is no fiber loss and no water is consumed. These lightweight nonwovens — in the range of 30 to 40 grams per square meter (g/m2) — may be used for applications including artificial leather and automotive, among other applications. Dilo’s inventions Hyperpunch and Cyclopunch have speed of 150 meters per min (m/min) and stroke frequency of 3,000 per minute. Dilo demonstrated the machine with a needle density of 45,000 needles per m per board, a barb depth of 20 to 40 microns, and throughput speed up to 140 m/min at 2,000 strokes/min. Dilo Group machines can also process aramids, glass fiber, P84® and polypropylene (PP), which is useful for composite applications.

Woven Reinforcement Structures — Germany-based Lindauer DORNIER GmbH’s A2 air-jet weaving machine debuted at ITMA 2023 and hence, its stall was very busy. This new machine provides improved efficiency, as well as enhanced flexibility and reliability to technical textiles. Electronically controlled systems monitor and control reliable weft insertion. DORNIER Composite Systems® is designed to produce high-quality reinforcement fabrics. World renowned, the P2 roving weaving machine produces reinforcement fabrics using carbon, glass and aramid fibers. Tritos® PP equipment manufactures multilayer textiles with complex structures for composite reinforcements using digital weave patterning, rapid rapier motion for low filamentation, and flexible shed geometry. Protos® TW is a tape weaving machine that can process strip-like materials such as fiber reinforcement tapes and films using zero twist feeder. Lastly, Protos® TP machine is used for UD tape which can be either be coated with a binder or impregnated with thermoplastic resin.

Switzerland-based Jacob Müller Group exhibited the Narrow Fabric Loom NFM 53 2/130, which can make spacer fabrics, tapes, rigid webbing and elastic ribbons with controlled thread transports suitable for all yarn types.

Knit Reinforcement Structures— COMEZ International, a member of the Jacob Müller Group presented the DNBF/EL-800, an electronically controlled raschel type warp-knitting machine that can produce 3D knitted fabrics, tubular fabrics and nets for the automotive industry. It operates at a higher speed compared to the previous models. Müller also offers the NH2 53 8/27 needle loom that uses the Z6 weaving system to make spacer fabrics suitable as reinforcements in lightweight composite materials and can provide good compressive stability by incorporating monofilaments.

Germany-based Karl Mayer Group showed new digital developments and applications of artificial intelligence to change patterns without making manual adjustments. It demonstrated the HKS 3-M ON, which is the fastest three-bar tricot machine and a compact warp knitting machine, as well as a warp knitting machine with magazine weft insertion to produce technical textiles with reduced weft yarn waste and increased working speed and width. The KM.ON dashboard is user-friendly and tackles the issue of global shortage of skilled workers. MULTI-MATIC® 32 Compact was the highlight in the warp preparation area. Karl Mayer also offers composite machines for producing biaxial and multiaxial textiles, fiber spreading lines and fiber reinforced thermoplastic tapes.

BIAXTRONIC® II can produce biaxial layer structures; COP MAX 4 can produce multilayer, multi-axial structures; MAXTRONIC® can produce high performance glass fiber composites; and COP MAX 5 can process carbon fibers and lightweight textiles. UD 500 AND UD 700 are fiber spreading machines that can produce fiber tapes from continuous filament yarns. SIM.PLY UD can produce tapes up to a width of 800 millimeters (mm).

Impregnation, Coating, Lamination Lines For Prepregs & Composites

At ITMA 2023, Sweden-based IPCO AB highlighted its Thermo-Press Systems and Scattering Systems. IPCO’s scatter system can deposit powdered, granular and fibrous materials onto a carrier material up to 1800-mm-wide. Applications include composites, nonwovens and textiles. ScatterPro F can scatter fibers like glass and carbon uniformly using key features such as a special agitator for uniform distribution, optimized scattering roller to hold the fibers, a rigid or adjustable doctor blade, easy change of the brush roller and a scattering roller with digital position display to adjust the distance between the two rollers.

IPCO manufactures double belt presses used in composites produc-tion. Its presses include ThermoPress TB, which has Teflon®-coated belts and counter pressure elements to make multi-layered materials, mixed thermoplastics, carbon fiber, glass fiber, and composite sandwich sheets. ThermoPress CB is used in making fiber-metal composites. ThermoPress SB is a high-pressure steel belt-based double belt press technology used to make high performance metal-plastic composites. IPCO has a 1,600-square-meter center of excellence testing center in Germany that has a full range of processes from impregnation, lamination, and consolidation to tempering and cooling. The company can consolidate prelaminate sheets and impregnate fibers with resin which can be applied in liquid, film, or powder form on a felt or nonwoven material.

Germany-based BRÜCKNER Trockentechnik GmbH & Co. KG, exhibited innovations for textile coating and finishing at ITMA 2023. Its finishing line for glass mesh fabric and for construction reinforcements is the Techno-line TT glass fiber finishing line. OPTI-COAT KA/KC coating unit has a simple and com-pact design with combined floating knife-/knife against cylinder unit. Woven and knitted fabrics can be processed for end-use applications including technical lightweight protection materials and air bags.

Since 1949, Germany-based Maschinenfabrik Herbert Meyer GmbH has been making fusing, laminating, and scattering machines and presses. At its booth a Technical Sales representative mentioned that the company has bonding technology for composites like honeycomb sandwich sheets and fiber reinforcement composites; and for technical textiles like powder coating and impregnation. For prepregs, the flow behavior of the thermoplastic adhesive is important as the fibers need to be optimally encapsulated. Prepreg makes semi-finished products for end-use components. For this application Meyer has laminating machines that can generate high pressure linearly as well as surface wise. These prepregs can be used in televisions, notebooks, mobile phones, the aviation and automotive industries and for lightweight construction components. The KFK-P is a high pressure at elevated temperatures laminator used for processing fiber reinforced composites and other composites. Some technical highlights are hydraulic belt tension, hydraulic pressure by the means of pressure rollers and pneumatic surface pressure.

Meyer also offers a production line to make glass mats from glass rovings with the help of a cutting unit that cuts the roving into a defined length and spreads them evenly on a conveyor belt. Then a powder scatterer distributes the adhesive powder. An infrared preheating station helps fast melting of the adhesive to increase the production speed. Applications of the lamination and scattering machines are tempering and sintering of UD-/Machine Direction (MD)-layers, coating of UD-tapes, thermoconsolidation of UD-/MD-layers, connecting of single UD-tapes to large-area layers and, production of UD-/MD tapes in different effective direction.

Meyer’s thermoconsolidation press is suitable for carbon layers or any other material that requires high processing temperatures. The temperature can go up to 400°C.

Italy-based Matex S.r.l. has expertise in coating and finishing machines since 1973. At ITMA 2023, it showed a reverse cylinder coating head with features including independent driving system, tension control for adjustments with lightweight materials, trays for continuous recirculation, gap control using digital display, removable roller and cleaning tray which help with easy maintenance. The machines can do direct coating and transfer coating with a knife or rotating cylinder. Matex also has impregnation equipment such as Rotocomp for impregnation of composite substrates with carbon, glass, or aramid fibers. Rotocoat, Rotomark, Rotopharm, and Rotosplit are its lamination lines. End-use applications include soundproofing for offices, automotive and filtration.

Zappa Macchine S.r.l., Italy, was founded in 1860, and its long history brings experience and knowledge in hot melt lamination, coating, impregnation, calendaring, flock, prepreg and powder scattering. With coating head model HSM-2, blade in air and blade over roll coating is feasible. This technology is used in applications like prepregs, technical textiles and traditional textiles. The head can be customized per a customer’s requirements and has accurate blade gap settings. Width ranges from 500 to 6,000 mm, and mechanical speed is 0 to 40 m/min. The company also highlighted a rotogravure head that can coat different water-based resins on a fabric for the Brinatura “frosted” effect. It can apply micro-dots of resin using different engraved rollers. The head also may be used to apply special effects such as lamination with metallized film. The web width of this machine is 1,600 to 3,600 mm and mechanical speed is 0 to 40 m/min.

Italy-based COS.T.A. S.r.l. designs industrial lines for applications including synthetic leather, tannery, carbon fiber dip coating and furniture edge banding. COS.T.A. offers high-performance dip coating technology for carbon fiber, fiber-glass and Kevlar® that can be used for prepreg preparation. The company also has lab lines for research and development, self-adhesive technology, technical textile laminations and hot melt lines.

Germany-based A. Monforts Textilmaschinen GmbH & Co. KG presented the Montex®Coat coating unit which can coat using air knife, roller knife, magnetic doctor blade, rotary screen printing, paste and foam coatings — hence, can offer a lot of tailor-made solutions from one source. It has improved features including saving setting time, handheld control device, and automatic edge limiters for immediate adaptation to changing coating widths.

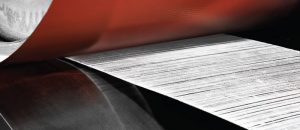

Source: Photo taken at Van Wees booth during ITMA

The Netherlands-based Van Wees UD and Crossply Technology B.V. entered the composite industry in 1994. The company is proud to be the only company to offer UD and multi-axial cross-ply technology. It manufactures UD thermoplastic resin impregnation machines, fabric prepreg (thermoset) impregnation machines, crossply machines, lamination lines, creels and other custom-built machines. It also offers product and development services at its Research and Technology Center (R&TC).

Van Wees displayed a variety of samples at ITMA including glass fiber PP, a crossply roll of carbon fiber PP; materials used for soft applications such as sailcloth and flexible protection materials like bullet resistant vests; and flax fiber reinforced polymer.

At Van Wees, technology offers a spreading section, impregnation section, and final winding using tension control on every yarn. The fibers that may be process on these machines are glass, carbon, aramid fibers and ultra-high-molecular-weight polyethylene (UHMWPE), which are converted to UD tapes using dispersion resin. These tapes are then used as raw materials for the multiaxial UD or crossply machines to make composites with various fiber orientations and layers.

The three machines Van Wees offers for impregnation of fibers and fabrics are dispersion impregnation, thermoset impregnation by reverse roller coater, and thermoplastic resin impregnation with inline extruder. The dispersion impregnation is stable with high impregnation due to easy penetration at the speed of 20 m/min. The thermoset prepregs are made in one step process by reverse roller coater at a speed of 3 to 10 m/min. For impregnation of thermoplastic resins, the film is made by melting the polymer in an extruder and metering the film thickness on impregnation roller at a speed of 3 to 15 m/min.

VanWees also has equipment for making flakes, which can be compression molded on a press to make make products. For flat panels, it has heated tables on which the materials is consolidated using vacuum pressure only. All the equipment used in-house is commercially available.

Van Wees also has expertise in testing and consultation, and has inspec-tion machines at its research facility, as well as drumwinders that can mimic the processes as it would take place in actual crossply and UD production.

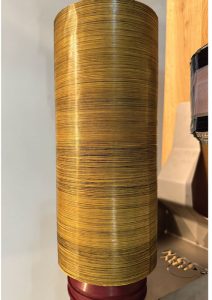

Source: Photo taken at Texmer booth during ITMA

Accessories For Enhancing Composite Production

Texmer GmbH & Co. KG, Germany, specializes in developing and supplying creels for all winding materials that can be pulled off both tangen-tially and overhead. A motor on the creel calculates and controls tension from full bobbin to empty bobbin. The company developed patented tension balancing systems that provide a substantial number of adjusting possibilities. Texmer has experience with high-quality pneumatically braked creels characterized by short response times, high operational safety and extremely low wear. Diameter control secures trouble-free operations. These creels are made for technical yarns and tapes. Specially coated guide elements help reduce carbon fiber damage to a minimum and increase process reliability. It is particularly important for low yarn tension glass roving creels to have exact control. Pneumatic mandrels have unrolling solutions for glass fiber roving without a twist. The yarn comes in minimum contact with the Texmer creel and can be drawn as far as possible without deflection. A polyacrylonitrile (PAN) precursor creel can hold bobbin diameters up to 1,000 nanometers and weight up to 500 kilograms (kg). All positions are individually controlled. Once the controlling unit of the electronically controlled creels is adjusted it will maintain a required thread tension by accelerating or decelerating the motor during operation.

Topocrom GmbH, Germany, offers Topocrom® surface structure for wear and corrosion protection that helps extend the service life of machine parts. It is challenging to process technical fibers such as carbon, aramid, glass and basalt fibers because they can be very abrasive. If the fiber filaments break, tear, stick or splice it can lead to interruptions in automated operations, which often happens because of the unsuitable surface of the guiding element. Topocrom employs a chrome electroplating process. Base materials suitable for chrome plating include steel, steel alloys, cast iron, stainless steel, copper, copper alloys, titanium and titanium alloys. The roughness of the surface can be changed by altering the current during electroplating and Topocrom coating can prevent splicing, wrapping, adhesion of filaments, reduce dust formation and increase wear resistance.

Van Wees also develops creels with features such as regulated yarn tension with manual or automated adjustment for each individual row or the entire creel. This is helpful when processing yarns like nylon, polyester, aramids, and UHMWPE. In the case of carbon fiber, it supplies special eyelets to avoid twisting the tows. Van Wees’ glass roving creel can handle heavy rolls up to 25 kg.

Switzerland-based Retech AG provides heat treatments for filament yarns with high-quality components, machines and in-process monitoring systems. The company demonstrated intriguing sustainable advancements for heated godets that are crucial in manufacturing synthetic yarns. Retech presented the new “blue line” tem-perature controller UCR-6/CR-7 and transmitter UTR-4 /UTR-4A. The new devices are sustainable as they con-sume less energy, which reduces the overall cost while producing exceptional results. Retech presented its innovation in a customized draw frame with godet, Internet of Things (IOT) technology and (super) slow speed drive concept. It presented vibration measurements, bearing temperature display and induction temperature measurement; and its demonstration unit explained the negative temperature effects and vibrations. The newly developed algorithms, monitoring devices and sensors can achieve higher productivity, less downtime and a longer lifetime.

Germany-based Osthoff-Senge GmbH & Co. KG demonstrated one of its singeing machines that often is a first step in finishing. Woven and knitted fabrics comprised of cotton, viscose and glass fibers may be treated. The display machine was five feet wide and ran at a speed of 100 m/min.

Conclusion

Textile composites play a significant role as innovations in lightweight performance materials used in sleeves for electron volt batteries or artificial leather for high-end fashion brands, among other applications. The theme for ITMA 2023 was “Transforming the World of Textiles” and the event featured 20 sectors of innovations including composites, although composite technologies remain a relatively small focus. Some companies specialize in composite technologies, while other companies are focused on manufacturing such as braiding, nonwovens, knitting and woven reinforcement that may be used in composite applications. At ITMA, several companies demonstrated the ability to process high-performance fibers on their machines, provide research and development consultation and testing and contract manufacturing. Overall, this year’s ITMA unveiled remarkable advancements in improving process sustainability by reducing waste and adding smarter and faster technologies to make machines more automated and efficient.

References:

1 Romeo RIM. (n.d.). What Are Composites? – Romeo RIM. Retrieved July 19, 2023, from https://romeorim. com/what-are-composites

Editor’s Note: Prateeti Ugale is a Ph.D. student in Fiber and Polymer Science and a research and teaching assistant at NC State University’s Wilson College of Textiles, Raleigh, N.C.

September/October 2023