manufacturing process that can deposit additional fiber in specific areas on a

flat needlefelt.

Nonwovens technologies can be used to produce an array of products for an ever-increasing number of end uses.

TW Special Report

Evidence suggests the earliest means of turning fibers into cloth was through felting, which makes use of the scaly structure of wool to firmly interlock the fibers together. Some of the manufacturing techniques employed in today’s nonwovens industry are derived from this ancient fabric formation method, while other techniques are a product of modern engineering developed to work with man-made materials. The origins of today’s modern nonwovens industry are not clear, but according to the Nonwovens Institute, Raleigh, N.C., the term “nonwoven fabrics” was first used in 1942 when fabrics were manufactured by bonding fiber webs using adhesives.

In the decades since the term was coined, the innovations have turned into a dazzling array of technologies for making products for filtration, automotive, medical, hygiene, geotextile, agrotextile, floorcovering and even apparel applications, to name just a few of the applications. Here, Textile World presents information on some of the newest technologies available to producers of nonwoven fabrics and products.

DiloGroup

Engineered nonwoven systems manufacturer DiloGroup, Germany, offers a unique additive manufacturing process called the 3D-Lofter, which was originally introduced as a prototype at ITMA 2019. The process essentially uses a separate sliver feed mechanism that functions in a similar manner to a digital printer. The sliver is fed into an aerodynamic web-forming unit, which allows additional quantities of fiber to be placed three dimensionally in specific locations on a flat needlefelt. The added fiber can be placed to avoid thin areas and build up stress points, alter textures, build mountains or fill valleys in the base web, and even allows for colored or patterned designs in the resultant web. Dilo reports the technology offers a fiber saving potential of up to 30 percent of the total fiber mass because once the even, flat needlefelt is created, only the fibers required are then used. The resulting web may be compacted and consolidated using needling and/or thermofusion. Applications include formed needlefelt parts for automotive interior linings, upholstery and mattress products, apparel and shoe applications, and floor coverings with colored patterns.

DiloGroup also offers the IsoFeed single card feeder technology — an aerodynamic system featuring numerous 33-millimeter-wide individual web forming units placed over the card’s working width. These units can dose web or fiber strips in the running direction where they are needed to combat mass variation in the web. According to Dilo, the IsoFeed can produce web mats from the card feeder with an improved CV value of approximately 40 percent. Additional advantages of IsoFeed include fiber consumption savings when the same minimum weight is the basis for a comparison between traditional and IsoFeed feeding; and the web is visually improved and more homogeneous. Web mats from the IsoFeed process are suitable for card feeding, for feeding aerodynamic web forming units, or may be used directly in needling or thermobonding processes.

Oerlikon Nonwovens, Teknoweb Materials

Germany-based Oerlikon Nonwoven offers comprehensive technologies for meltblown, spunbond and airlaid nonwovens. For meltblown products, Oerlikon offers stand-alone mono and bicomponent equipment or the option of “plug & produce” inserts positioned between an upstream and downstream spinning system, such as spunbond, to manufacture products with a barrier or liquid impervious layer. Oerlikon Nonwoven reports its airlaid technology is perfectly suited to producing nonwovens from pulp or cellulose fibers. Its process also permits homogenous mixing of diverse raw materials and is gaining attention for use in sustainable recycling applications.

The latest offering from Oerlikon Nonwovens is the Procter & Gamble (P&G) PHANTOM patented technology. Teknoweb Materials — Oerlikon’s partner for hygiene products and wipes — has an exclusive license from P&G to distribute this technology worldwide. Developed by P&G for hybrid nonwovens, Phantom combines airlaid and spunmelt technologies for wet and dry wipe products. According to Oerlikon Nonwoven, the two processes are merged into one step to combine cellulose fibers, long fiber including cotton, and possibly powders with man-made fibers. No hydroentanglement means it is not necessary to dry the nonwoven, which offers cost savings. The process can be adjusted to optimize required product characteristics including softness, strength, dirt absorption and liquid absorption. Phantom technology is perfectly suited for wipes production, but also may be used for absorbent core products such as diapers.

ANDRITZ Nonwoven

Austria-based ANDRITZ Nonwoven reports its key competencies lie in drylaid, wetlaid, spunbond, spunlaced, needlepunched nonwovens, including converting and calendering.

Andritz offers technology for producing biodegradable, sustainable nonwovens including spunlace lines, Wetlace™ and Wetlace CP. The lines can process wood pulp, short-cut cellulosic fibers, viscose, cotton, hemp, bamboo and linen without the use of any chemical additives. The company offers customized trials in its advanced technical center in Montbonnot, France, which recently was updated with an innovative pulp application system for carded-pulp wipes.

Andritz’s latest technology for biodegradable wipe nonwoven production is its neXline wetlace CP. This innovation combines two forming technologies — inline drylaid and wetlaid web forming — with hydroentanglement for bonding. According to the company, natural fibers such as viscose or pulp, can be processed smoothly to produce a high-performance and cost-efficient carded-pulp wipe that is fully biodegradable.

The company recently acquired France-based Laroche S.a.s., which adds additional drylaid fiber preparation technology — including opening, blending, dosing, airlay web forming, textile waste recycling and bast fiber decortication — to the Andritz portfolio. The acquisition adds value in the recycling sector with complete recycling lines for post-consumer and industrial waste, which can produce fibers for respinning and nonwoven end-uses. As part of the Andritz Group, the company is now known as ANDRITZ Laroche S.a.s.

Allertex Of America

In the United States, Andritz Laroche is represented by Allertex of America Ltd., Cornelius, N.C. According to Allertex’s Technical Sales & Business Development director Jason Johnson, Laroche’s technology is perfectly suited to the rapidly emerging U.S. hemp fiber market. “We see a huge interest currently in the decortication, cottonization and refining of hemp fiber in nonwovens for building materials, wipes, automotive uses, furniture and composites,” Johnson said. “Combined with Laroche opening, blending and airlay technology, as well as Schott & Meissner’s Thermofix technology, the sky is the limit!”

The Thermofix-TFE double-belt press flatbelt laminator from Germany-based Schott & Meissner Maschinen- & Anlagenbau GmbH uses a combination of contact heat and pressure. The product to be processed passes through the machine between two Teflon™-coated conveyor belts. Once heated, the material moves through one or more calibrated nip rollers into a cooling area to thermoset the material. The Thermofix-TFE is suitable for textiles used in outerwear, reflecting strips, artificial leather, furniture, glass mats, filters and membranes, among other applications. Thermofix is available in two models and three different sizes for handling varying capacities.

Allertex specializes in supplying recycling and nonwovens technologies including opening and blending, web forming, bonding, finishing, bast fiber processing, and lamination from a variety of companies.

Trützschler Nonwovens

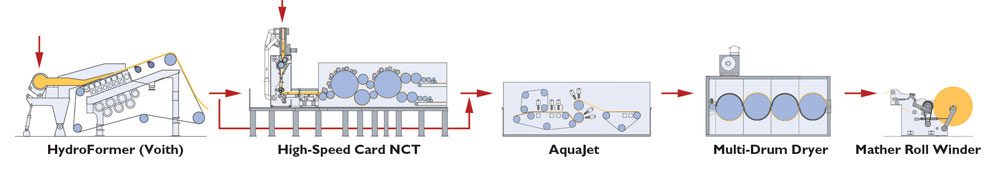

With an increased demand for high-quality, single-use cleaning wipes, Germany-based Trützschler Nonwovens has introduced a carded pulp (CP) solution for producing a sustainable, non-man-made-fiber nonwoven more affordably using its AquaJet spunlaced technology. Trützschler along with partner Germany-based Voith GmbH & Co. KG introduced the WLS wetlaid/spunlaid environmentally-friendly wipe process to the market in 2013-14. The WLS lines use cellulose-based blend of pulp from plantation wood and short lyocell or viscose fibers, which is dispersed in water then wetlaid and spunlaced.

Trützschler Nowovens’ latest CP development advances the WLS concept one step further by combining a wetlaid, pulp-based web with a carded web made using longer viscose or lyocell fibers. The wetlaid pulp provides the required absorbency and additional volume to the nonwoven, while the web enhances the softness and wet strength. The AquaJet’s high-pressure water jets bond both layers into a functional nonwoven.

The CP production line features an NCT high-speed card between Voith’s HydroFormer wet web former and the AquaJet. This configuration is flexible — the card may be bypassed to produce a WLS nonwoven using only the HydroFormer and AquaJet; the wetlaying process may be omitted to produce a classic carded, hydroentangled nonwoven; or the HydroFormer, NCT card and AquaJet may all be utilized to produce a two-layer CP nonwoven.

According to Trützschler Nonwovens, its Poland-based customer Ecowipes has seen strong demand for the nonwovens produced using a CP line that was installed in the fall of 2020.

wetlaid web layer and an NCT high-speed card for creating the carded web layer.

Reifenhäuser Reicofil, Reifenhäuser Enka Tecnica

Germany-based Reifenhäuser Reicofil GmbH & Co. KG — a specialist in spunbond, meltblown and composite lines, and a business unit of Reifenhäuser GmbH & Co. KG — offers sustainable options for producing nonwovens. According to the company, its Reicofil lines can process up to 90-percent polyethylene terephthalate (PET) from post-consumer waste for use in industrial applications. The company also offers technologies for producing hygiene products using sustainable materials such as diapers made using bio-based raw materials.

In addition, Reifenhäuser Reicofil has solutions for medical protective items such as face masks. The company recognizes the need for 100-percent reliable fabrics for such applications and guarantees highly reliable machinery for producing nonwovens with filtration efficiencies of up to 99 percent to meet N99/ FFP3 standards. West Bridgewater, Mass.-based Shawmut Corp. recently acquired nearly 60 tons of specialized, high-precision meltblown machinery for its new Health & Safety business unit from Reifenhauser Reicofil (see “Shawmut: Investing In The Future Of Advanced Materials,” TW, this issue).

“In applications in the hygiene, medical and industrial sectors, we regularly set benchmarks for productivity and end-product quality,” said Markus Müller, sales director, Reifenhäuser Reicofil. “In addition, we offer our customers the option to produce sustainable nonwovens from bio-based raw materials or recycled material. We support our customers in leveraging the opportunities offered by the global shift to sustainability — or in other words: Next Level Nonwovens.”

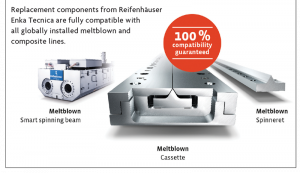

Germany-based Reifenhäuser Enka Tecnica specializes in custom-designed replacement smart spinning beams, cassettes and spinnerets that are compatible with any existing spunbond or meltblown line. Its capabilities allow a manufacturer to upgrade existing lines and enter new markets including hygiene, medical or filtration. Enka Tecnica reports the high caliber of the nozzle tips and capillaries assure consistent product quality and precision. Its meltblown spinning beams also incorporate an optimized sustainable energy concept for reduced preheating times and increased heat output. “Our primary concern is the satisfaction and success of our customers,” noted Wilfried Schiffer, managing director, Reifenhäuser Enka Tecnica. “That’s why a personal relationship with our customers is just as important to us as the punctual delivery of our very high-quality products. A long-term cooperation based on trust means more to us than turning a quick profit,”

Both Reifenhäuser Reicofil and Reifenhäuser Enka Tecnica are represented in the United States by Fi-Tech Inc., Midlothian, Va.

Graf + Cie.

Switzerland-based Graf + Cie. — a member of the Components Business Group of Rieter — is a manufacturer of clothing for flat and roller cards. For the nonwovens industry, Graf offers its Hipro Metallic Card Clothing. According to Graf, an innovative geometry used in the design may boost throughput by up to 10 percent in nonwovens applications compared to conventional clothings. The Hipro teeth feature a specially designed hump at the front, which increases fiber retention, according to Graf. An optimized web transfer from the cylinder to the doffer increases production by up to 10 percent, and fewer failures occur in the web thanks to a precise fiber transfer to and from the cylinder.

The clothings, suitable for both high-performance and conventional cards, are available in a variety of steel alloys and a choice of surface finish so they may be tailored to the application and the fibers to be processed. Hipro Card Clothings are designed for all man-made fiber types processed in the nonwovens industry and are compatible with different rollers including workers, doffers and condenser rollers. Graf reports Hipro is ideally suited for applications in the hygiene, medical, automotive, filtration and floor covering markets.

BRÜCKNER

Over the past few years, Germany-based BRÜCKNER Trockentechnik GmbH & Co. KG has developed its nonwovens portfolio considerably. The company offers ovens and dryers for nonwovens applications including:

- Supra-Flow BX — an air-through double-belt thermofusion oven for high-loft nonwovens used in mattress insulation, seat cushions and upholstery;

- Supra-Flow BA — an air-through thermofusion oven for lightweight nonwovens used in hygiene applications;

- Supra-Flow BE — an air-through dryer for lightweight nonwovens used for abrasive cleaning pads, kitchen wipes, surgical tablecloths and feminine care products, among other applications;

- Supra-Flow BH — an air-through dryer for high-speed spunlace lines; and

- Power-Frame — an air-impingement tenter for thermal treatment/drying of needlefelts, bitumen carriers for roofing membranes, high-temperature filters and geotextiles.

In addition, Brückner’s nonwovens product range comprises impregnation units, coating units, accumulators, calibration calenders, lamination calenders, cutting machines and winding machines. Brückner has a technology center at its headquarters location in Leonberg, Germany, where customers may run trials. Brückner is represented in the United States by Fi-Tech.

Idrosistem

The quality of the water used in spunlace manufacturing processes is important. Italy-based Idrosistem S.r.l. specializes in water filtration systems for spunlace lines that remove fibers from the water to avoid issues with injectors and finished product quality. The company’s latest offering was designed to control bacteria in the water loop during wet wipe production. The technology uses a chlorine dioxide water sterilization system to keep toxic matter, in particular chlorides and bromate-based products, out of the production water. Idrosistem reports that the sterilization system maintains its efficiency independently from the pH of the water and can reach the lowest limits for bacteria control required in terms of colony forming unit per millimeter (CFU/ml). The system also acts as a powerful algaecide, bactericide, virucide and sporicide, according to the company. Idrosistem is represented by Fi-Tech in the United States.

SAUERESSIG Surfaces

Germany-based Saueressig Surfaces, a Matthews International Corp. company, is an established designer and manufacturer of sleeves and embossing rollers for decorating spunbond and thermally bonded nonwovens. The company uses the latest laser-engraving methods as well as evolved molettage techniques. Hardened rollers, microporous shells, basic and structure dams expand the customization options. Recent developments include new 3D embossing and apperturing options offline using high-precision heated rollers with complex and exact engraving patterns; or inline during the hydroentangling process using nickel sleeves. These developments make designs with 3D effects possible with improved tensile strength and elasticity, and high air/liquid permeability. Saueressig also can produce 3D samples — taking base material, engraving pattern, basis weight and color into account — so customers can develop optimal solutions for their end products.

Saueressig Surfaces is represented in the United States by Fi-Tech.

Ultrasonic Bonding Technology: Sonobond Ultrasonics

Nonwovens are non-traditional fabrics and traditional cut-and-sew methods may not be the most effective way to produce end products using nonwovens. The onset of the pandemic and need for personal protective equipment (PPE) in particular created increased interest in ultrasonic technologies — those that use high-frequency sound waves to heat and plasticize man-made fiber nonwoven fabrics.

According to West Chester, Pa.-based Sonobond Ultrasonics, ultrasonic bonding technologies can quickly create strong, sealed edges and secure barrier seams that meet regulatory requirements. These high-quality bonds at pressure points create finished products without stitch holes, glue gaps, fraying or unraveling. No thread is needed, and production tends to be fast for greater output.

Sonobond offers bonding, seaming, slitting, cutting and trimming equipment and often, more than one function may be performed on the same unit in a single step. Sonobond’s SeamMaster® Ultrasonic Sewing Machines are the company’s most popular technology. SeamMaster offers continuous, patented rotary operation for strong, sealed, smooth and soft seams. According to the company, the machine can be used in a wide variety of assembly applications since more than one function may be performed at one time. For example, with the necessary tooling, the SeamMaster can bond, seam and trim in one quick step. Sonobond reports the speed is up to four times faster than when using a traditional sewing machine and up to 10 times faster than adhesive machines. The machine also is configured similar to a traditional sewing machine, so minimal operator training is required to operate the SeamMaster.

Applications for Sonobond’s technology in the medical nonwovens market include face masks; surgical gowns; disposable shoe, pillow and mattress covers; and lint-free wound dressings. Filtration products that may be made using Sonobond’s ultrasonic technologies include pleated HVAC and HEPA filters; air, liquid and gas filters; heavy-duty filter bags; and spill clean up cloths and oil containment booms.

To help a customer decide on the best technology for their application, Sonobond offers a free Ultrasonic Bonding Viability Test using the customer’s nonwoven materials. The customer then has the opportunity to see the results and understand the capabilities of the available products.

Emerson

St. Louis-based Emerson offers Branson ultrasonic equipment that can slit, bond, seal or quilt man-made fiber nonwovens for medical and non-medical applications. The company reports a major advancement is the ultrasonic welder’s ability to monitor and record welding data in real time. This enhances the customer’s quality control capabilities and allows for continuous improvements even in automated lines.

Another recent advance is the addition of Fieldbus capabilities in Branson’s DCX F ultrasonic welding system, which allows multiple welding systems to connect to each other and communicate directly with a programmable logic controller. Fieldbus allows the user to control weld parameters for an individual ultrasonic welder and also monitor the status of a multi-welder production system using an electronic dashboard. In this manner, the user can optimize the production process and address issues as they arise.

Herrmann Ultrasonics

Herrmann Ultrasonics Inc., Bartlett, Ill., offers a new ultrasonic technology for anchoring elastic threads in diapers. The company’s innovative process creates a tunnel between two layers of nonwovens and guides the stretched elastic through the tunnel. The fabric is then welded in specific bonding areas before it is cut and relaxed. The new anchoring process may be executed continuously or intermittently. According to the company, the method simplifies elastic handling, reduces the risk of breakage, increases the process window and lowers production costs. Herrmann reports it has successfully tested a range of material combinations, different size elastics and elongations, and varying speeds.

“This new process, we call ‘Anchoring’, will support our North American customers even better, as they strive to create products that are softer and more sustainable,” said Uwe Peregi, president, Herrmann Ultrasonics Inc.

Herrmann also has updated its ULTRABOND ultrasonic generator with new controls that can trigger the ultrasonic vibrations quickly and in the right place instead of generating a continuous signal. This update makes format-dependent tools, such as a format anvil drum, unnecessary. Herrmann notes that overall equipment efficiency is improved with reduced tool costs and less time required for format changes. Combining the Ultrabond generator signal with its MICROGAP technology — which controls the gap in the bonding area — allows multi-dimensional process monitoring to ensure consistent bonding quality and direct system feedback.

All of the latest nonwovens innovations are sure to be on display at the upcoming INDEX™20 nonwovens event in October 2021. The expo also will be available in a parallel virtual format for attendees who are unable to be there in person. See “Global Triennial Nonwovens Show Moves Ahead,” TW, this issue, to learn more about INDEX.

July/August 2021