A myriad of advanced planning and scheduling (APS) software offerings give textile companies the ability to choose the best systems for their production needs.

Dr. Kristin A. Thoney-Barletta

At ITMA 2019, a variety of different types of textile software were showcased. There were many textile supply chain solutions among the options, and this article focuses specifically on advanced planning and scheduling (APS) for supply chains tailored to the textile industry.

A software company’s focus on the textile industry can be a key advantage for a textile manufacturer looking for an APS system, since this focus often means software company employees are much more familiar with textile processes. In addition, the software usually incorporates more of the functionality required to plan and schedule textile processes, which may require less customization to successfully implement the system within a textile company. Textile functionality can save a textile company significant time and money to get the software fully operational.

Computer House

Italy-based Computer House S.r.l.’s PROTEX software contains an enterprise resource planning (ERP) solution with an Oracle database. The ERP solution consists of a sales module and a production module. Functionality within the production module includes cost control and quality control. Schedules are created that minimize a cost function. The user can assign different weights to different parts of this cost function, and the cost function can include meeting delivery dates. PROTEX also is a manufacturing execution system (MES), a warehouse management system (WMS), and a customer relationship management (CRM) system. It is not a product lifecycle management (PLM) solution, but Computer House does collaborate with a specific PLM vendor if this functionality is required by the client. PROTEX can be used in spinning, knitting, warping, weaving, dyeing, finishing, and cut and sew operations. It has many applications in all segments of the textile industry, including apparel and home textiles.

According to Computer House, advantages of PROTEX ERP include that it is developed entirely in-house, is an integrated and easy-to-use with intuitive graphics, and is multi-company and multi-language.

Datamon+

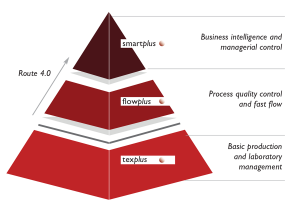

Spain-based Datamon+ offers TEXPLUS, an ERP system that has costing and quality control. It plans production and performs scheduling with dispatching rules. The software has specialized solutions for spinning, weaving, dyeing, finishing, printing, and industrial laundries. The company currently sells its software in Spain, Portugal, and Latin America.

Datamon+ software offers control, improvement, and cost effectiveness, according to the company. Its main benefits include increased profitability, immediate information for negotiations and decision making, inventory optimization, quick response to problems, and meeting customer quality specifications.

Datatex

Datatex has offices in Switzerland, Germany, India, Israel, Italy, and the United States. Its ERP system incorporates sales and customer service — including CRM — planning and scheduling, production order management, quality management, inventory and warehouse management, purchasing, costing, and financial management functions. Application-specific products include shop floor automation, fabric inspection, machine capacity management, machine queue management and PLM. Datatex has many solutions including those for fiber, spinning, knitting, weaving, printing, dyeing, apparel, nonwovens, technical textiles and carpet.

Shannon McCarthy, vice president of Business Development, Datatex, said that are several advantages of Datatex products. The company focuses exclusively on the textile industry — except for a few cases in which one of their textile customers has expanded into another industry — and the software has been developed for more than 20 years in response to their customers’ needs. Not only does Datatex do detailed scheduling, it handles load balancing among machines in different locations.

Datatex reports: “Textile and apparel manufacturing have very different and particular planning and scheduling requirements. Therefore, the Datatex planning and the Datatex scheduling systems have proven to be one of the key success factors to our customers.”

(Image courtesy of inteos®)

Halo

Austria-based Halo GmbH offers its Inteos® software package, which is an ERP, MES and monitoring solution. Inteos also has quality control and warehouse management functions. In terms of planning and scheduling, it handles capacity planning and reservation, rough and detailed planning, optimization, and simulation. The software does not have PLM capabilities. Inteos can be used in weaving, knitting, finishing, printing and apparel operations.

Stefano Sampietro, salesman at Halo, said that he feels that that the main advantage of Inteos is that the company is continuously developing and innovating. For example, it recently added tablet capability, and also is moving into augmented reality. According to the company: Inteos provides “a product that can be integrated quickly and smoothly into current operations. The system is customized to suit your individual needs and the user-friendly and easy-to-understand platform allows for a minimum of training and guarantees maximum acceptance among users.”

Intex

Intex is ERP and MES software developed by Germany-based Intex Consulting GmbH. The company also has offices in China, India and Brazil, among other locations. It partners with Oracle and also is a member of the SAP Extended Business Program. Modules within Intex include sales, production, inventory, purchasing, costing and quality management. Scheduling is based on both meeting due dates and minimizing costs. Intex also contains a shipment model and has CRM and PLM functionality. It allows the user to schedule sampling on machines and provides detailed tracking of sampling costs. Intex can be used in fiber, spinning, warping, weaving, dyeing, finishing, and cut and sew operations. The software has been implemented in a variety of industries, including apparel and home furnishings.

According to Dileep Kumar, senior consultant, Intex Consulting Group, there are many advantages of Intex. It has integrated planning across the system and is a finite capacity scheduler. Actual costing is performed throughout the supply chain. Intex also enables users to estimate accurate delivery dates during the course of a phone conversation and suggests similar products if the desired product cannot be produced on time. Additionally, it allows companies to determine who their best customers are from a profit point of view. The company reports: “Including our co-operation partners and our international subsidiaries, more than 100 textile and software specialists are selling and implementing our solutions worldwide.”

Porini

Italy-based Porini S.r.l. distributes its software through a channel of partners. The Porini Suite for Microsoft Dynamics 365 consists of Porini 365 ERP, Porini 365 CRM, Porini 365 Apps and Porini Analytics. Porini 365 CRM is a solution for fashion retailers. Porini 365 ERP is for fashion, retail, footwear and textiles. It includes functionalities for spinning, weaving, knitting, dyeing, finishing, printing, cut and sew, and distribution. The scheduling module calculates requirements based on due dates and process constraints.

The system suggests a schedule based on one of several different algorithms, including first in, first out (FIFO) and priority schemes. Porini takes into account quality control, and if quality specifications are not met, it blocks work-in-process (WIP) from advancing on its route and finished goods from shipping to the customer. The software has MES, advanced warehouse management capabilities and PLM capabilities.

According to Fernando Pereira, international sales director, Porini, a major advantage of Porini is its offer of a complete suite of integrated software components based on the latest Microsoft technologies. All software is cloud-based and deployed with a subscription fee and is accessible by browser. Updates occur seamlessly. Porini integrates easily with Microsoft PowerApps, Power Automate and PowerBI, as well as the standard Office suite. Porini reports the company has more than 350 projects in the different streams and 25,000 active users.

Schaeffer Productique

France-based Schaeffer Productique’s software includes the ERP/CRM SOLINSyst and has capabilities in inventory management, costing, scheduling, quality control and logistics. It can be used in knitting, weaving, dyeing, and cut and sew operations. The software, used primarily by European companies although there are some implementations in North Africa, has been implemented in many industries including apparel and home textiles.

The company reports “We integrate the changing needs of the international textile industry with the latest advances in digital technologies to support our customers in their evolution. We regularly bring them the most relevant solutions, at the best conditions.” Schaeffer Productique counts 200 customers in 12 countries.

Up Solutions

Italy-based Up Solutions S.r.l. offers the Just MES software, which is not an ERP system, but is compatible with many ERP systems. Up Solutions is a Microsoft partner. The Just SUITE consists of the following four integrated solutions: just plm, just planning, just monitoring and just quality control. There is one just SUITE for fashion, and a separate one for textiles and technical textiles. Companies only have to purchase the integrated solutions that they need. For example, carpet manufacturers often only use the just monitoring textile solution. With the textile just planning solution, there are specific programs for spinning, knitting, weaving and dyeing. The just planning solution also has warehouse management functionality. Just MES does not yet have a program for cut-and-sew operations. The just planning solution incorporates the option to source production or schedule production. When the user decides to schedule, priority is selected within scheduling heuristics. Just MES has been implemented in such industries as home textiles, apparel, shoes, and carpet. Most recently, it has been used in the automotive industry.

In describing Just MES, Up Solutions reports: “We have now achieved a fundamental goal for us: to offer a complete solution capable of managing and monitoring the entire manufacturing process of the company … Thanks to our consolidated experience in the textile and apparel sector, we are now able to satisfy all those production companies that need to monitor and improve their supply chain.”Just MES currently has 160 customers in 30 countries.

Interlem GP Omega

Italy-based Interlem GP Omega S.r.l. focuses mainly on small and medium-sized enterprises. Its products include the Arianna Textile ERP solution, the Arianna Printing ERP solution for digital printing and the Net@Pro MES solution. The software has functionality to be used in spinning, warping, weaving, dyeing, printing and finishing. It is not currently for cut-and-sew operations. The software has been used for many end applications, including apparel, home textiles and making carbon fiber. The software has finite capacity scheduling, and the user may put weights on different factors, including due dates and costs. It has CRM and WMS capabilities with order picking. It does not have PLM functionality. Interlem GP Omega sells primarily to the European market, and its ERP solution is generally not sold outside of Italy.

Andrea Picone, managing partner, Interlem GP Omega, said that one key advantage of its system is its flexibility. According to the company, other benefits of using the software include speed improvement, production lead time reduction, waste reduction, delivery completeness, punctuality and resource optimization. Net@Pro has more than 16,000 users in Italy and 200 user companies.

LOOMDATA® software includes plant monitoring, quality control and

warehouse tracking.

Zeta Datatec

Switzerland-based Zeta Datatec GmbH offers LOOMDATA® software, which is both an ERP and MES system. The company delivers both the hardware and software. The system includes plant monitoring, quality control and warehouse tracking. It also can be used for planning. LOOMDATA did not historically have a lot of automated scheduling functionality. However, one of its new features is forward and backward scheduling of orders. Furthermore, the company is willing to customize the software for clients who require more scheduling functionality. Its software is specifically for weaving, knitting and finishing. It is not used for spinning or sewing operations. The software also does not have PLM capabilities. Industries Zeta Datatec serves include textiles, technical textiles, plastics, pharmaceuticals, cosmetics, food and paper.

Zeta Datatec Co-Owner Werner Zberg said that there are a lot of advantages to using LOOMDATA. He believes that LOOMDATA can more quickly integrated into companies. The software runs on an HP server with Sun Solaris, and he believes that this is a more stable environment. “Having installed more than 550 systems in 50 different countries around the world, our over 35 years of experience in providing powerful monitoring and planning solutions for the textile industry has given us the ability to produce the most stable and reliable system in the world today,” reported the company.

Choosing A Supply Chain APS System

There are a lot of options available when choosing a supply chain APS system. Among the software options discussed above, there are significant variations in the software capabilities, types of textiles processes for which the software system was designed, and the final products of textile companies in which the software has been implemented. In addition, some of the software companies have a strong international presence, while others have focused on a particular region. Some of these regional companies may be looking for new opportunities to expand, while others may be content to be regional players.

Before evaluating different supply chain APS software, textile companies should:

- clearly define the benefits expected by implementing the new software;

- determine how the software will integrate with and/or replace existing software;

- decide how the software will fit into existing business procedures; and

- agree on the essential software functions necessary to achieve the desired benefits based on business procedures.

This information, combined with textile company product and process details, can be used to narrow down which commercial packages seem to best match the company’s requirements.

The remaining supply chain APS software can be further evaluated based on a more detailed assessment of both software capabilities and whether company constraints can be met. In terms of software capabilities, having an APS system that automatically generates detailed finite capacity schedules and outputs dispatching lists for individual machines might be very important to a company. If that is the case, can the software provide that capability? If so, how are those schedules generated?

Textile companies should also develop a comprehensive list of business and manufacturing constraints, in conjunction with production managers and machine operators. They should find out which if these constraints can be modeled in the base software system and which would necessitate customization. In addition to evaluating commercial APS systems, textiles companies should consider the alternatives of developing software in house and/or hiring a consultant experienced in supply chain planning and scheduling to develop specialized software. A cost-benefit analysis of each acceptable option should be performed based on a detailed cost breakdown and a well-thought-out estimate of the anticipated financial benefits.

Many APS software packages for textile supply chains were presented at ITMA 2019. By carefully analyzing requirements and constraints, in conjunction with software benefits and costs, textile companies can make the most informed decision as to whether such a system; a generic, non-textile-specific APS system; developing software in house; or hiring an experienced consultant is the best decision for the company.

Editor’s Note: Dr. Kristin A. Thoney Barletta is professor, head & director of Undergraduate Programs in the Textile and Apparel, Technology and Management Department at NC State’s Wilson College of Textiles.

September/October 2020