Ultrasonic welding equipment is an essential technology for producing nonwovens-based personal protective equipment.

By Mark Cragin

By any measure, global demand for medical-grade face masks and N95 respirators soared in early 2020 with the onset of the COVID-19 pandemic. The World Health Organization estimated that 89 million medical masks are needed globally each month just to protect medical providers. Yet the demand for masks goes much, much further than protecting medical personnel. In some 50 countries, ordinary citizens are also seeking masks — or making their own — to comply with government mask-wearing mandates and recommendations from the Centers for Disease Control and Prevention (CDC).

The rapid onset and circumstances of the pandemic have stressed medical supply chains worldwide and resulted in a huge shortage of personal protective equipment (PPE), particularly face masks. The suddenness of the global shortage made many types of PPE hard to obtain at any price. The shift has led governments, medical manufacturers and product buyers worldwide to rethink the value of maintaining, or recreating, a domestic supply of medical-quality face masks.

And so, manufacturers in the United States, Australia, India and other countries have joined China — the global market leader — in expanding and strengthening their supply chains for face mask production with investments in expanded nonwovens capacity and new face-mask production lines. According to market estimates, purchases of face masks will occur at dramatically higher rates for the next five to seven years.

In the southeastern United States, the region’s medical manufacturers continue to gear up production of surgical face masks and N95 masks to meet demand. For the producers of ultrasonic welding equipment — the equipment used to bond multiple layers of nonwovens into a mask product — the demand has been felt in constant meetings, continuous quoting activity with manufacturing engineers and systems integrators, a spike in the sales of ultrasonic equipment, and greatly increased demand for startup and technical support for welding equipment associated with mask production.

The low cost and utility of nonwoven fabrics have made them essential in the global battle to prevent the spread of infection. When built into PPE such as medical face masks, gowns and scrubs, and even foot covers, disposable nonwovens can provide effective and inexpensive protection against microorganisms. The key to their effectiveness is in multilayer construction, which combines an inner layer weighing 10 to 25 grams per square meter (g/m2), an outer layer of spunbond polypropylene (PP) weighing 25 to 40 g/m2, and a middle layer typically 25 g/m2 of meltblown PP fibers.

The low cost and utility of nonwoven fabrics have made them essential in the global battle to prevent the spread of infection. When built into PPE such as medical face masks, gowns and scrubs, and even foot covers, disposable nonwovens can provide effective and inexpensive protection against microorganisms. The key to their effectiveness is in multilayer construction, which combines an inner layer weighing 10 to 25 grams per square meter (g/m2), an outer layer of spunbond polypropylene (PP) weighing 25 to 40 g/m2, and a middle layer typically 25 g/m2 of meltblown PP fibers.

While the inner and outer spunbond PP layers provide protection and structure, it is the middle layer of meltblown PP fibers that is key to filtering out pathogens. If the meltblown fibers in this layer are negatively charged during manufacturing, they can attract and hold extremely small particles. Technology like this, together with expert design and high-quality manufacturing, is why a product like the N95 respirator mask can effectively protect medical personnel working with COVID-19 patients.

Ultrasonic Welding In Mask Construction

The ultrasonic welding equipment that is essential to the production of medical-grade face masks and respirators is often, but not always, embedded within larger, fully automated mask-production machines. These machines typically are fed by two or three rolls of nonwoven material — the inner, middle and outer layers — which are processed continuously.

Simply explained, ultrasonic welders convert electrical energy to high-frequency mechanical vibration, which is transmitted using tooling into thermoplastic material. The vibration creates frictional heat that melts the plastic, an operation that can be focused and utilized to:

- cut or slit a large roll of nonwoven fabric into narrower strips — cut edges are simultaneously seamed/ sealed by the heat;

- “quilt” multiple layers of nonwoven material into a laminated product such as a multilayer face mask, or;

- bond multiple layers of nonwoven fabric into a finished seam — the edge of a face mask, for example — or attach a nonwoven tie strap or stretchable nonwoven ear loop to the edge of a mask.

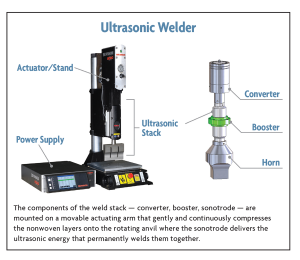

The basic structure of an ultrasonic welder used for nonwovens resembles that of a sewing machine in many respects. Layers of material are drawn continuously across a flat surface, moving between the weld “stack” on one side and a rotating wheel — the weld “anvil” — on the other. Components of the weld stack — a converter, booster and sonotrode — are mounted on a movable actuating arm that gently and continuously compresses the nonwoven layers onto the rotating anvil. There, the sonotrode delivers the ultrasonic energy that welds the layers together as the face of the rotating anvil embosses the finished seam.

Because a typical face mask requires two welded seams — on at the top and one at the bottom — on both its width and its length, as well as two bonds on each side to hold tie or elastic straps, an automatic mask-making machine incorporates multiple ultrasonic welding stations. Parallel welders continuously seam across the top and bottom width of the mask in the first step of the process. Then, after mask laminates are cut to size, they move perpendicular to the line and proceed through another parallel welding station that seams their length on both sides, again using a continuous weld that takes place as material moves across a rotating anvil. From there, precut straps are positioned and plunge or “point” welded at the top and bottom — this time onto a flat anvil — completing the construction of the mask.

Ultrasonic welding technology, together with well-designed machinery and automation, makes nonwoven fabric bonding seem almost effortless. However, it takes a lot of technology and skill behind the scenes to focus high-frequency vibration into a force that cuts, quilts and bonds with medical-grade precision and reliability.

The control of the welding process — the electronics and programming that power the stack and deliver the weld energy — originates in the welder’s power supply, carried to the working welding components by cabling. Most welding operations involving nonwovens utilize a 20 kiloHertz power supply, which can be accessed for programming through an onboard human machine interface (HMI) display or a networked computer connection. For continuous welding operations on nonwovens, many mask-machine builders rely on Emerson’s Branson™ DCX power supply, which features a powerful, compact design with closed-loop amplitude controls, advanced diagnostics and easy configurability.

In addition to a flat or rotating anvil, the other crucial weld system components are those in the stack, which is mounted on an actuating arm and comprises:

- a converter, which converts electrical energy from the power supply into mechanical vibrations of the proper frequency for welding,

- a booster, which increases or decreases the intensity of the vibration as needed, and

- a sonotrode, or horn, whose shape and composition are specifically designed for the nonwoven cutting or bonding task at hand.

Before and during the introduction of ultrasonic welding technology at a medical nonwovens facility, it is common for ultrasonic welding experts to work closely with the manufacturer to develop and optimize all aspects of the technology. Often, each nonwoven welding application requires a specialized sonotrode and an optimized set of weld parameters. These parameters, typically created using a DOE approach, provide a range of proven weld program settings that allow the production equipment to adapt to ordinary process and material variations while delivering quality welds.

Benefits, Efficiencies Of The Ultrasonic Process

Whether ultrasonic welding is used to produce face masks and respirators, surgical garb or any of a range of other medical PPE, the benefits relative to other production methods have made it an essential technology for processing nonwoven materials used to combat COVID-19 and other diseases. These benefits include:

- Exceptional speed and productivity. Ultrasonic welding technology cuts, seams and bonds nonwovens with exceptional speed. In continuous production lines, ultrasonics can weld nonwoven layers in a fraction of a second, creating repeatable bonds that are as strong as the parent material.

- Strong, continuous seams and bonds. Compared to sewing, ultrasonic technology offers major benefits because it creates high-strength, high-integrity seams and bonds without the need for thread and without creating mechanical holes in fabrics, which can hold and conceal microorganisms or contaminants.

- Zero consumables or contaminants. Compared to adhesives, ultrasonic technology eliminates the added expense of consumables, the added effort of application, the added time required for setup and drying and the added risk of exposure to chemical contaminants. Ultrasonic seams are ready for use as soon as they are produced.

- High energy efficiency. Ultrasonic technology only consumes power when it is being used to cut or bond material. Also, since the process generates required frictional heat instantly using vibration, there is no additional energy consumption or waste associated with preheating and maintaining heat knives or hot bonding tools at required operating temperatures.

- Continuous technical improvement. Ultrasonic technology for nonwovens continues to evolve and improve, often leveraging new features and capabilities developed for other industries. For example, the latest Branson ultrasonic equipment for nonwovens production — the Branson DCX-F system — incorporates Fieldbus communication capabilities that allow multiple individual systems to link together. This allows the user not only to control the weld parameters for an individual system but also to monitor the status of an entire process.

Editor’s note: Mark Cragin is the Southeast regional manager for Assembly Technologies at Emerson offering Branson Ultrasonic welding technologies located in Lawrenceville, Ga.

July/August 2020