ITMA 2019 showcased the latest innovations in digital printing from early innovators and newcomers to the market.

By Dr. Lisa P. Chapman, Technical Editor

First introduced at ITMA 1991, textile inkjet printers were a novelty coloration process marketed toward sampling and high-end short runs because of the low production speed of 10 meters per hour (m/h). At ITMA 2019, nearly 30 years after this technology was first shown, textile inkjet printers reached speeds of 90 meters per minute (m/min), making this technology now highly competitive with rotary screen printing.

With speeds equaling and some instances surpassing rotary printers, textile inkjet printing holds a competitive advantage because it eliminates the screen preparation process and offers the ability to hold print information in a digital format up until production. By eliminating the screen and jetting the colorant, inkjet printing allows for more flexibility in the print repeat size, enables an increase in the number of colors without increasing cost, provides capability for finer line detail, and reduces water and energy consumption. The fine line detail and increased number of colors can produce a near photographic image on the textile substrate; and the elimination of repeat sizes enables the print designer to engineer a print within the scale, shape, and optimal position of the textile product, enabling new product categories. However, the digital nature of inkjet printing is driving this technology as manufacturers are seeking ways to bring products to market faster in order to quickly respond to consumer demand.

Single Pass Versus Scan-Type Printers

The increase in inkjet printer speeds is attributed to changes in the configuration of the printhead system, which allowed an increase in nozzles. Scan-type printers operate by moving the printhead carriage back and forth across the substrate. Although considerably faster than when first introduced, the upper limit of scan-type printers is typically about 300 m/h, with the exception of the Mini Lario — manufactured by Italy-based MS Printing Solutions S.r.l. — which can print up to 600 m/h. Single-pass printers print at significantly higher speeds because the print head system is arranged such that the fabric is fed under a fixed print unit and the fabric moves under the print bars at a constant speed building up the print image across the full width of the substrate by one stroke or pass of vertical image. In single-pass printing, each printhead station jets one color of cyan, magenta, yellow, or black (CMYK) with the capability to add up to four additional stations of colors such as blue, green, violet, grey, red, or orange. The footprint of single-pass printers is considerably larger than scanning mode printers, however the speed of single-pass printers often justifies the large square footage.

Single-Pass Printers

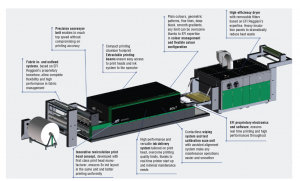

At ITMA 2019, five single-pass printers were displayed. Today, dozens are installed globally. Italy-based EFI Reggiani — a division of Electronics For Imaging (EFI) Inc., Fremont, Calif. — introduced the newest single pass printer, the 1.8-meter-wide Reggiani BOLT, which can achieve print speeds of 90 m/min at a 600 x 600 dots per inch (dpi) resolution. The printhead has capability of variable drop sizes ranging from 5 to 30 picolitres (pL). An innovative, optional, feature of the Bolt printer is that one or more integrated analogue printing stations can be included to be used for special effects such as a metallic pigment or as a pre-treatment device.

The Bolt printer is the fifth single-pass printer to be shown at ITMA with four previously premiering at ITMA 2015. The four other single- pass printers are MS Printing Solutions’ Lario, Japan-based Konica Minolta’s Nassenger SP-1, the Netherlands-based SPGPrints’ Pike, and China-based Atexco’s Vega One. Information also was provided at ITMA for a six single-pass printer from Switzerland-based Mouvent, with its name to be determined, but the printer was not displayed and is not yet commercially available.

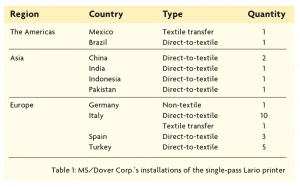

MS Printing Solutions, a Dover company, has 27 Larios installed worldwide; 24 of which are predominately used for direct to fabric printing, two for textile sublimation and one for a non-textile application (See Table 1). The Lario has production print speeds of 75 m/min for textile substrates — enabling 20,000 to 80,000 meters per day of printed fabric — and 120 m/min for paper printing. At ITMA, MS showed an innovative in-line pre-treatment method for reactive inks that consisted of laying a foam onto the belt under the fabric, and then adding pressure to the top of fabric to force penetration of the pretreatment.

Konica Minolta’s Nassenger SP-1 has a total of 1,024 channel heads with independent-drive, and variable drop sizes from 6-30 pL. The company developed its own printhead which allows flexibility in the ink adjustment so that dark and light colors may be combined during the printing process. The printer can be configured for up to nine colors with capability to use reactive, disperse or acid dyes.

Konica Minolta’s Nassenger SP-1 has a total of 1,024 channel heads with independent-drive, and variable drop sizes from 6-30 pL. The company developed its own printhead which allows flexibility in the ink adjustment so that dark and light colors may be combined during the printing process. The printer can be configured for up to nine colors with capability to use reactive, disperse or acid dyes.

The Nassenger SP-1 prints high definition prints with fairly good ink penetration from the face to back of the fabric. Another notable capability of this printer is an automatic printhead cleaning and empty nozzle detection system to maintain stable production and reduced down time. To further decrease printer down time, the Nassenger SP-1 is equipped with a fabric wrinkle-detection function and concave printhead nozzle surfaces to prevent transport problems. The Nassenger SP-1 can achieve print speeds of 60 m/min.

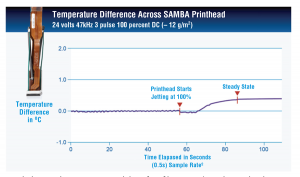

SPG Prints’ Pike printer has printing speeds of 40 to 90 m/h depending on the desired print quality. The Pike uses Samba printheads from Santa Clara, Calif.-based Fujifilm Dimatix Inc. that incorporate a recirculating ink channel system that prevents ink clogging. In addition, the printhead maintains thermal stability for the duration of the print run. This robust design enables SPG to provide 18 months of warranty on the printheads. A unique feature of the Pike is that it uses the Archer® technology, whereby the head print plates can be positioned 3 to 6 millimeters (mm) away from the substrate, which greatly reduces the risk of a head strike. Typically, printheads are positioned 2 to 3 mm above the substrate, which poses a risk to the printhead if the fabric is wrinkled. Archer technology can accurately jet across a much greater distance than other printheads while still achieving a native resolution of 1200 x 1200 dpi. The Pike can be configured with six to nine printing stations, and each print station has a dedicated Archer print bar containing 43 print heads with variable drop sizes from 2-10 pL and a jetting frequency of 32 kilohertz (kHz).

Atexco’s single pass Vega One high-speed printer can print 80 m/min for production capacity of 8,000 to 10,000 meters per day. The high-precision printhead nozzles can print with up to 1,900 pixels per inch. The Vega One also is capable of printing one side of fabric, scanning for alignment, and then printing the reverse side. This novel feature is suitable for double sided printing of products such as scarves and flags and may solve the issue of poor ink penetration that has proved problematic for inkjet prints.

Scan-Type Printers

While increased production speed of single-pass printers was highlighted at ITMA 2019, so too was the refinement of scan-type printers. New to the specialty print market, Twine Solutions Ltd., Israel, premiered a machine for printing sewing thread on demand. Thread can be dyed in millions of colors immediately and on demand, creating unique colors, shades or even gradients. New to the textile inkjet printer market, Hewlett-Packard Co. (HP), Palo Alto, Calif. — traditionally a manufacturer of printers for paper and signs and banners — showed the STITCH S Printer Series for disperse printing on both transfer paper and textile rolls. In addition Spain-based KERAjet, inventor and pioneer of digital ceramic printing technology for floor tiles, showed a high-speed digital textile printer.

Zimmer’s COLARIS

Austria-based Zimmer Austria Inc. showcased its pigment printing capability with the COLARIS 96-3400 — a 3.4-meter-wide digital inkjet printer that can be outfitted with up to 96 printheads. This flagship printer is suitable for textile applications and allows a capacity beyond 1,000 square meters per hour (m2/h). Zimmer demonstrated an inline drying system with a small footprint that uses a unique infrared technology in combination with a vacuum suction system to cure the pigment. Colaris printers may be used with a variety of colorants such as reactive, disperse, acid, pigment, and vat for printing lightweight to very heavyweight fabrics that require colorant penetration through the substrate such as carpeting, towels, and plush or heavy automotive and home décor fabrics. Zimmer has several Colaris pigment installations in Europe and Asia and the first unit in the United States also was recently installed. For the U.S. market, Zimmer has focused on home décor and digital camouflage printing, thus the emphasis on pigment and vat colorants.

The Colaris series of scan-type printers ranges from 2.2 to 5.2 meter print width, while the COLARIS-NF is a single-pass printer for narrow fabrics. In-line pre-and-post treatments systems can be added to improve print quality and increase ink penetration. The MAGNOROLL GMA and CHROMOJET (CHR-DPT) are inline pre-treatment applicators, the first for lighter- to medium-weight fabrics and the second for medium to heavy substrates such as terry towels, flocked fabrics, velour, and even carpet. The SUPRAPRESS press station can be added as an increased penetration and equalization device to ensure maximum penetration on products like carpets or PES blankets. The SUPRAFIX SHS is a combined, horizontal color fixation system using optionally saturated steam, superheated steam or hot air according to the amount of ink being used. The fixation activity is controlled by a flow through steam/hot air stream and ensures the highest penetration, ink fixation and drying in a single pass at the shortest possible time.

The Colaris printers are equipped with Fujifilm Dimatix’s StarFire™ SG1024 compact industrial printheads. The printhead is available in four models for Colaris printers, each with varying drop size capability:

- The X-Small printhead is for very light fabrics less than 150 grams per square meter or when excellent definition, fine contours or super smooth gradations are required with drop sizes from 7 to 21 pl;

- The Small or SA model is intended for printing of light- and medium-weight home decor, apparel, and flag substrates that can achieve ink penetration with drop sizes ranging from 12 to 35 pl;

- The medium or MA printhead has capability of 30-75 pL drops and is best suited for medium-weight carpets, velours, terry cloth and low to medium plush piles; and

- The large or LA model printhead is capable of 75 to 180 pL drop sizes for ink penetration of voluminous substrates such as heavier weight carpet, furs, and plush blankets.

If both fine line definition and penetration is needed then there are two options — choose the small SA printhead size and print with higher resolution to achieve more ink laydown; or using a medium MA or large LA printhead, operate the head only using the smallest drop size to get the fine contours.

KERAtex MP

KERAjet has introduced its industrial printhead technology to textiles. Its machines are available in three widths — the KERAtex MP 3400 has print widths up to 3.4 meters; the KERAtex MP 2400 has print widths up 2.4 meters; and the KERAtex MP 1800 has print width up to 1.8 meters. Regardless of the model, all of the Kerajet series printers are fully configurable for up to 10 colors of any water based dyes or pigments colorants, up to eight printheads, and have open platforms for colorant and raster image process (RIP). Kerajet printers feature Fujifilm Dimatix’s StarFire 1024 printhead.

HP Stitch

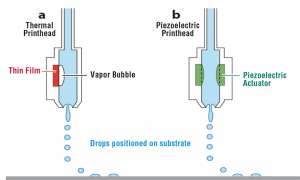

HP debuted the Stitch series of printers with native 1,200 dpi printhead resolution for vivid colors and deep blacks. This low maintenance printer can print unattended at production speeds of up to 220 m2/h. HP is one of only a few printer manufacturers that also own and operate printhead factories and the company taken advantage of its research and development capability to bring a series of printers to the market that they use thermal rather than the piezoelectric printheads. With a piezoelectric printhead an electric charge is applied to the piezo crystal causing a vibration that forces ink out of the printhead nozzle. With thermal printheads the ink is rapidly heated, generating bubbles that expel the ink through a nozzle. The vast majority of textile ink printers on the market use piezoelectric printheads. Generally thermal printheads are less expensive, but in the past, there was compatibility issues with some types of colorant. HP has managed to develop a disperse ink suitable for a thermal printhead. In addition, HP thermal printheads enable more nozzles — up to four times as many — therefore when a nozzle is out, others can fill the gap. Unlike piezoelectric which is sensitive to heat, the thermal printhead allows for a drying to occur in the print zone enabling the ink to dry immediately upon deposition on the paper allowing for lighter-weight papers for sublimation.

The Stitch S1000 can print up to 3.2 meters wide at speeds of 10 m/h for a six pass, highest quality print and up to 18.7 m/h at maximum speed. A spectrophotometer is built into the printer to enable online calibration across multiple printers, regardless of the location of the printers. The Stitch S1000 also is equipped with an optical media advanced system with a photo capture capability to ensure optimal medium feed throughout the print run.

Single pass printers offer speeds and prices that are competitive with rotary screen printing, however scan-type printers are still the predominate type of textile inkjet printer because the lower cost allows printing service providers to install more printers, with the flexibility of varying colorant type or printer manufacturer within their factories. Scan-type printers are also suitable for companies starting up an inkjet printing division who don’t want a large capital investment before learning how to optimally implement the new technology into their existing manufacturing process. And of course, the lower cost of these printers still meet the needs of sampling, prototyping and specialty print markets. Research and development continues in machine technologies such as fabric handling, printhead capability and robustness, quality control mechanisms for nozzle failure and fabric wrinkle detector systems; and chemistry developments in colorant and pre-treatment. For successful implementation of this technology still needed is optimization of the printing supply chain for process, water, energy, and price reduction.

January/February 2020