What does it mean for a textile to be intelligent?

By Dr. Vicki A. Barbur and Dr. Amy Heintz

Innovative sensors, coatings and novel materials designed to capture information, respond to the environment or deliver value-added performance functionality are generating new possibilities for textiles. These possibilities may represent opportunities for disruptive product offerings for wearable fabrics and industrial textiles.

Conductive Coatings: A Smart Approach To Intelligent Textiles

According to Albany, N.Y.-based Transparency Market Research’s report titled “Global Smart Textile Market to Expand at 30.8% CAGR Due to Increasing Demand in Military and Healthcare Sector,” the market for smart and intelligent fabrics is expected to grow to more than $7 billion by 2023.

The applications driving this growth range from consumer sporting goods to sophisticated medical and military uses. Smart and intelligent fabrics are already considered as a means to help athletes monitor, improve and maximize performance; regulate body temperature for patients in surgery or intensive care; recognize and signal stress or duress in firefighters and others exposed to extreme environments; or transmit data from sensors embedded in textiles within our environment to a smartphone application or central control point for monitoring and timely preventative action. Potential industrial applications include temperature-regulating textile mats for use in aviation and interior design, systems that prevent icing of airfoils, and moisture-sensing fabrics for the construction industry.

Many of these potential uses rely on an essential physical attribute embedded within innovative intelligent textiles: conductivity. The newer conductive fabrics are capable of transmitting electricity, a property that can be leveraged to produce heat or to transmit information in a dynamic way without the need for traditional embedded wires. Conductive properties can be used to deliver additional valuable performance attributes; for example, they can provide sources of power necessary for operating distributed and embedded sensors and transmitting captured information to a remote computer or handheld device.

Conductivity can be integrated into fabrics using two main approaches — using conductive threads that are incorporated into the fabric, or conductive coatings that are applied to the fabric. Conductive threads include metalized natural or man-made fibers. Such threads are highly conductive and have been implemented for embedding devices such as radio frequency identification (RFID) tags. However, their stiffness and roughness can reduce the flexibility, softness and drapeability of the material. It also can be difficult to precisely control the electrical properties of the fabric as it stretches or to create complex arrays and/or patterns of conductivity.

Columbus, Ohio-based Battelle has developed a conductive coating using carbon nanotube (CNT) formulations that eliminates many of the problems associated with metallic threads or coatings or embedded wire systems. CNT coatings are highly conductive, flexible and lightweight and can be applied in a thin layer that moves with the fabric and does not interfere with its drapeability or other performance characteristics. The CNT coating can easily be integrated into smart and intelligent fabrics to deliver thermal properties or, alternatively, simply conductivity.

Smart Versus Intelligent Textiles: What’s the Difference?

Smart fabrics are textiles that have added performance characteristics delivered through embedded fibers or functional coatings. These characteristics may be purely aesthetic — such as the light-up or color-changing dresses that have been spotted on fashion runways — or may deliver performance benefits such as heat, antimicrobial barriers or localized delivery of active ingredients. These functions are delivered passively, without direct input from the environment.

Intelligent fabrics go one step further. They are able to sense and respond to a stimulus in their environment. Intelligent fabrics require not only the core performance function, but also some form of sensor that collects information from the environment and a mechanism for responding to input from that sensor to close the loop. Closed-loop control can be built in by combining sensors with heaters or other active technologies. A conductive coating is a critical enabler for providing this functionality.

For example, rather than simply delivering heat when activated, an intelligent fabric will respond to ambient room temperatures or a person’s body temperature to cycle heating on or off as required to maintain a temperature set point. Other applications include diagnostic fabrics that monitor vital signs and send information directly to a smartphone app that recommends the appropriate response action, or protective fabrics with active functional coatings that change color to warn their wearers of the presence of an environmental contaminant.

Some of these possible applications are entirely visionary for the moment and some are already in the development phase. The basic technologies exist to drive growth of these and other similar intelligent fabrics that could soon deliver a broad range of functions and performance characteristics.

Creating Coated, Intelligent Textiles

Coated textiles consist of two or more layers that are combined into a composite material. By carefully selecting the combination of base textiles and functional coating, manufacturers can produce textiles with many different possible combinations of desirable performance characteristics. The resulting coated textile will have combined properties that cannot be offered by either component individually.

- The base fabric provides the tear and tensile strength, elongation and dimensional stability of the composite material and supports the layer of coating applied to it.

- The coating controls the chemical properties and features such as abrasion resistance and resistance to penetration by liquids and gases. It can also provide functional properties, including passive functions — such as easy-to-clean or antimicrobial — and active functions — such as heat or sensing.

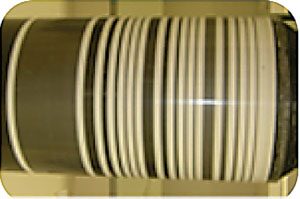

Smart coatings — which may include CNT, resins or polymers — can be designed to deliver unique functionality and performance characteristics, including conductivity, bacterial resistance or sensing capabilities. Many smart coatings, including Battelle’s CNT conformal coating, can be added to a textile via the same methods used for more traditional coatings, including knife coating, transfer, Zimmer coating, roll-to-roll and spray coating.

A Conformal Conductive Coating For Flexible And Irregular Textile Surfaces

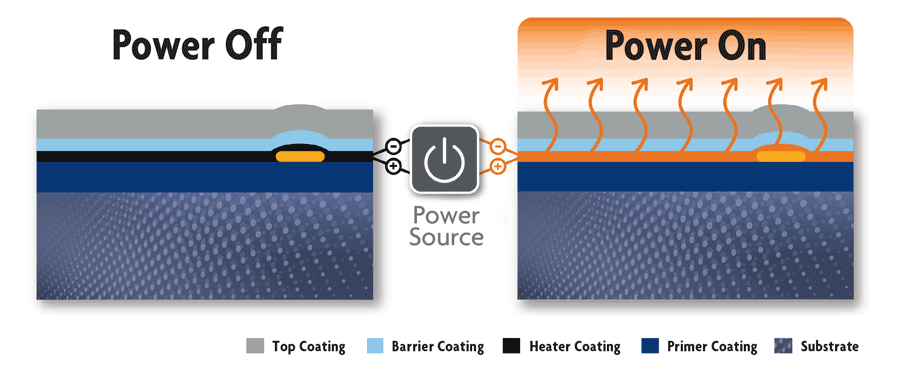

Battelle has developed a smart conductive coating with a unique blend of performance characteristics. The conformal CNT coating has been engineered for use on flexible or irregular substrates such as textiles (see Figure 1). It conducts electricity to deliver uniform warming, to power sensors and devices, or to transmit information. Unlike most conductive coatings, it does not negatively impact the properties of the fabric itself.

Most conductive coatings are engineered for use on rigid substrates and not ideal for use on soft, irregular or flexible substrates such as textiles. When applied to a soft or flexible substrate, these coatings typically lose conductivity as the material bends. They may also change the surface properties, making the substrate more rigid.

To take full advantage of the potential for conductive fabrics, the coating must allow for bending and flexing with the flexible substrate and maintain other critical performance characteristics. Battelle’s conformal conductive coating uses a formulation of dispersed single-walled carbon nanotubes (SWCNT) that is applied directly to the textile, forming a thin conductive layer that can generate heat or electricity when power is applied. Because the CNT coating can be applied very thinly while still maintaining high conductivity, it does not add unwanted weight or bulk or change the flexibility or drape of the fabric. It delivers uniform, predictable heat on soft, flexible and irregular substrates, maintaining conductivity even when bent. It offers several advantages over traditional methods for adding conductivity to textiles, for example:

- Maintains even conductivity as the fabric drapes, stretches and moves;

- No impact on fabric properties such as drape, softness and flexibility;

- Adds minimal weight and virtually no bulk when applied because the coating is typically no more than 3 micrometers thick;

- Applied in a transparent layer that allows fabric color and design to show through;

- Supports complex arrays and patterns for advanced intelligent textile applications that require zonal control, closed loop feedback or integrated antennae; and

- Requires minimal power for heating or electrical conductivity.

The coating is a result of more than a decade of internally funded research and development at Battelle. Through this work, researchers have optimized the properties, stability, manufacturing, integration and sustainment of CNT coatings and their products. The coating system has undergone rigorous durability testing throughout its development — including humidity, solvent and water exposure; corrosion resistance; cyclic bending; cyclic thermal loading; and high strain testing, which provides a high level of confidence in its use for a variety of applications.

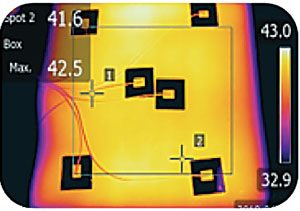

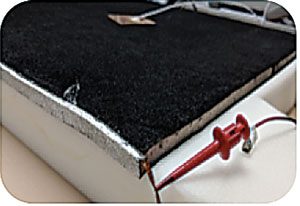

The CNT coating has already been proven in the aviation industry for anti-icing and de-icing for aircraft and Unmanned Aerial Vehicles (UAVs, or drones). Applying the technology to textile fabrics opens possibilities for many new applications for medical, consumer, industrial and military use. The technology has been demonstrated in several fabric-based applications, including a mat heater for composite airfoils and fabric warming system for thermoregulation therapy (see Figure 2).

Market Opportunities: Heated Fabrics

Heating is the first market opportunity for conductive CNT coatings. Rather than relying on embedded wires or integrated metallic threads, the CNT coating acts as the conductor for heated fabric applications. The high conductivity/low resistivity of CNT coatings means that heat can be generated from extremely thin films, resulting in lighter, thinner and more flexible offerings than existing textile heater technologies on the market. As result, there are significant advantages for current applications. Additionally, it opens new possibilities in areas where weight, thickness or conformability requirements have made heating difficult.

Possible applications include:

- Medical — Heated textile fabrics could be used to produce wearable garments that deliver improved comfort for patients and medical personnel in temperature-controlled operating rooms. Such products could also be used for thermoregulation therapy.

- Automotive — The automotive industry could produce seat covers with heating properties integrated directly into the fabric, saving energy and materials required for complicated circuitry. In addition, by using these CNT coatings on other interior surfaces of the car, it would be possible to provide zonal, customized and individualized heating for occupants.

- Furnishings and home goods — Heated fabrics could be used in mattress covers, upholsteries for sofas and chairs, blankets and other textile-based goods. Gentle heating from furnishings could help people stay comfortable with lower ambient temperatures, reducing overall energy costs.

- Building and construction — Responsive insulating materials could be used to wrap pipes and deliver heat during freezing weather conditions. Mat underlayment can also provide floor heating. Other fabrics could be made sensitive to environmental conditions such as moisture or other hazards using powered embedded sensors.

- Clothing — Thermally heated garments could improve comfort for military personnel, first responders, construction workers, athletes and others operating outdoors in inclement temperatures or indoors in low-temperature environments like operating rooms or refrigeration plants. Intelligent clothing based on smart textiles would also be capable of responding to a fall in temperature so that the wearer is never too hot or too cold.

Beyond Heat: Responsive Intelligent Textiles

While Battelle’s CNT coating has been optimized to deliver heat to the substrates it is applied to, there are many other potential applications for conductive CNT coatings. This technology is an enabling one for a whole host of wearable technologies or responsive textiles that require integrated sensors. For example, sensors could be used to detect and quantify moisture levels or other measurements such as motion, weight, orientation, light level or vital statistics. This captured information could be transmitted to a point of use using the conductive coating.

This technology therefore opens up a whole portfolio of potential intelligent textile opportunities, such as:

- Clothing that monitors patient health and reports changes to a mobile app for the patient or their healthcare providers;

- Sportswear that monitors performance and movement, eliminating the need to wear a separate fitness tracker;

- Performance clothing that extracts energy from the wearer’s movements to recharge or power mobile electronic devices; and

- Floor and wall coverings, such as carpets that light up in the dark to lead the way to emergency exits or bathrooms or wall coverings for bathrooms and laundries that sense over-accumulation of moisture.

Medical Monitoring And Bioelectronic Medicine

For many of the aforementioned responsive systems, multifunctionality is required. Multifunction — such as electrical, ionic, and/or thermal conductivity; charge storage or dissipation; moisture retention, for example — can be built into coating formulations and applied to textiles.

One potential application for these multifunctional fabrics is for medical monitoring or bioelectronic medicine. Comfortable, efficient wearable devices are key to enabling this new wave of intelligent medical technologies. For these devices to realize their full potential, they need stable and continuous electrical contact with the person. The current state of the art is to use a hydrogel to couple the electrode to the skin. However, system performance can change with time, temperature, humidity and the patient’s movements and position.

Battelle’s CNT coating can be combined with ionic conductors to create mixed ionic electronic conductors (MIECs) that provide consistent electrical contact with the skin. The MIECs are an interconnected network of electrical and ionic conductors in an elastomeric matrix. These three components provide the multi-functionality needed to maintain contact and electrical transport from the skin to the device.

The coating is incorporated into a fabric sleeve. The system provides several benefits over existing hydrogel systems including:

- Excellent conductivity with more efficient coupling with the skin;

- Conductivity maintained with extension over repeated cycling;

- Lower impedance with stainless steel current conductors;

- Lower power consumption; and

- Excellent flexibility and toughness and good mechanical properties.

Additional research is still needed to optimize the coating for wearable/washable fabrics, yet the possibilities of an integrated conductive CNT coating for textiles are nearly limitless. As demand for smart and intelligent fabrics and textiles in general continues to grow, Battelle’s CNT coating technology provides a new option for delivering resistive heating capabilities and conductivity for transmitting signals that will enable many applications not possible with today’s current technologies.

Editor’s Note: Dr. Vicki A. Barbur is senior director, IP and Technology Commercialization, and Dr. Amy Heintz is Technical Fellow, Battelle, Columbus, Ohio. Dr. Barbur can be reached at barbur@batelle.org. Battelle has been awarded several patents for its use of CNT technologies and the conformable conductive coating system. Now, the technology is ready for the next phase of development. Companies interested in exploring licensing or codevelopment may contact the company.

July/August 2019