Roadways and other paved surfaces can be subject to the damaging effects of sub-surface moisture-

and temperature-induced swelling and shrinking, and traditional geosynthetic materials haven’t been

especially effective in stabilizing the moisture content in the ground that underlies the pavement.

Especially in environments such as the Alaskan tundra — which is subject to frost heaves owing to

varying rates of expansion and contraction of the freezing and thawing water held in the soil — or

parts of Texas, Georgia and other warmer-climate states that have expansive soils — which are

stable enough when wet but which may dry up and crack in the heat of a severe summer drought — the

movement of the water in the soil affects the pavement as well and can cause it to buckle or crack

in response to that movement. What is needed is a way to equalize the moisture content throughout

the roadbed, which will help eliminate the threat of weather-induced damage to the pavement.

TenCate Geosynthetics North America, Pendergrass, Ga., part of the Netherlands-based Royal

Ten Cate NV’s TenCate Geosynthetics division, has developed a woven geosynthetic that is designed

to provide roadway stabilization in the face of extreme weather and environmental situations.

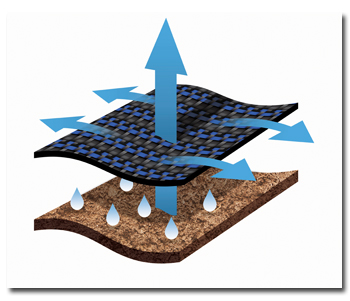

TenCate Mirafi® H2Ri is a double-layered fabric made with high-tenacity polypropylene filaments to

provide reinforcement and soil retention, and a yarn comprising patented hygroscopic, hydrophilic

4DG (deep groove) multi-channel nylon fibers that wick water out of the roadbed and move it

laterally through the fabric and thus mitigate the effect of frost heaves, or, alternately, the

uneven drying out of expansive soil.

The wicking yarns in TenCate Mirafi® H2Ri wick water out of the roadbed and move it laterally

through the fabric, thus mitigating the effects of differential settlement.

The development of Mirafi H2Ri came about following a meeting between representatives of

TenCate and the Alaska Department of Transportation (DOT), which was struggling with frost heave

problems on roadways in Alaska, according to Brett Odgers, market manager, roadway reinforcement,

TenCate Geosynthetics North America. “We turned the problem over to our product development people,

and they came up with a wicking yarn to help mitigate the DOT’s issues.”

Wicking yarns are used a lot in performance apparel, but they had not previously been used in

a geosynthetic stabilization application. Instead, Odgers said, road builders traditionally have

put down six to 12 inches of sand or aggregate that the water could move through, or they have

installed some sort of drainage net. “The problem with that is that if there are changes in the

grade, the water can’t move uphill and will pocket at the lower level. The benefit of H2Ri is that

water will move uphill as it is transported through the fabric.” This movement will help solve

problems caused by differential settlement because the moisture content is equalized throughout the

roadbed.

TenCate Mirafi® H2Ri is placed directly on the prepared site in an overlapped or seamed

arrangement, depending on subgrade strength, and then covered with fill.

According to TenCate, H2Ri has higher tensile modulus properties than traditional

stabilization products, and the double-layer construction with uniform openingsenhances the

separation, filtration and drainage functions.

“We developed the weave structure for some reinforcement products we came out with last

year,” Odgers said. “It allows us to use both the nylon and reinforcement yarns together, and it

gives a better flow through the fabric so it won’t trap water.”

This solution applies to environments other than the Alaskan tundra as well. “We’re doing

research now with the University of Texas, Austin, on using H2Ri for expansive soil applications,

and the preliminary work is pretty positive,” Odgers said. “Any time you need to reinforce and move

water out of the system, this will be useful, but these two applications — frost heave and

expansive soil — are particularly challenging.” He added that the same product would be used in

both applications.

For more information about TenCate Mirafi® H2Ri, contact Brett Odgers +913-909-7150,

b.odgers@tencate.com.

February 2012