possibilities with the solution-dyeing system developed by the company.

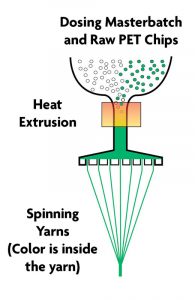

Using a proven industrial process to color synthetic yarns are they are extruded, e.dye® offers a more sustainable alternative to traditional chemical dyeing while also improving color performance.

TW Special Report

Solution dyeing is nothing new, but Hong Kong-based e.dye® Ltd. was formed by George Yang to develop a robust and sustainable solution for textile colorization in the fashion industry using solution dyeing.

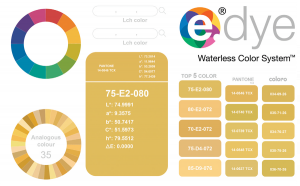

Yang’s vision to grow the company was to create more colors as well as sharable color recipes, and the initial effort that began in 2012 with six colors has grown into a library of approximately 10,000 color recipes.

e.dye operates an Innovation Center in China, e.dye Kunshan Ltd., that offers a color lab, testing facility, and pilot and production lines for its solution-dyed Waterless Color System™. The company also owns two SMARTEX™ production facilities — Smartex Solution Co. Ltd. in China, and Smartex Solution Taiwan Ltd. in Taiwan — where the masterbatch is made. Smartex also is e.dye’s captive converter of textiles.

U.S. Footprint

e.dye Americas Inc. was spun off from the parent company in October 2024. It is a free-standing corporation based in Portland, Ore., with Michael Murphy at the helm as the sole shareholder currently. “We created e.dye Americas in response to our customers asking for more on-shore, near-shore sourcing for reasons of saving transportation costs and pollution,” Murphy said. “It has also been useful in addressing the current tariff chaos!”

Murphy continued: “We have a unique capability to develop sustainable, long-lasting colors by deploying our vast library of color recipes to translate color from the designer’s mind into reality. We offer and can implement an entire supply chain solution, not simply create a color.”

Evolution Of Solution Dyeing

Solution dyeing has long been utilized in the production of carpets and upholstery, where limited color choices and high minimum color quantities (MCQs) are acceptable. However, the demands of the fashion industry necessitated crucial upgrades to this process, including reduced MCQs and a broader range of colors.

The e.dye® Color System

The e.dye Color System represents a transformative approach to coloring polyester and nylon yarns, leveraging solution- or dope-dyeing technology. This industrial process involves coloring yarns as they are extruded, offering a sustainable alternative to traditional chemical dyeing methods. e.dye addresses the environmental impact of dyeing and enhancing color performance, paving the way for better color solutions.

Through innovation and adaptation, e.dye has bridged the gap between traditional solution dyeing and the demands of modern textile industries. Central to this transformation is the development of SMART Colors™ and the ESP™ System, which collectively streamline the process of color creation. SMART Colors, with its curated palette, provides versatility and efficiency, enabling designers and manufacturers to respond swiftly to changing market trends. Meanwhile, the ESP System empowers brands with precision tools to refine their color strategies, ensuring a seamless integration of sustainability and performance.

Challenges In Color Matching And Consistency

Most brands encounter significant hurdles with current dyeing techniques, including poor color matching, consistency and colorfastness. These challenges often lead to product returns and unsaleable goods, particularly when colors bleed onto lighter shades during shipment or retail sales. e.dye’s advanced online color selection ESP System and its almost 10,000 searchable colors facilitates faster color development times, improved shade matching, and enhanced consistency, enabling brands to overcome common color failures.

Enhancements Through The ESP™ System

The digital ESP System serves as a cornerstone of e.dye’s advanced solution dyeing process. This plat-form enables brands to select existing color recipes for masterbatch colors — the foundational color ingredient in solution dyeing. By offering preconfigured recipes and streamlined color development pathways, the ESP System empowers brands to achieve superior results in record time. Additionally, it fosters collaboration and precision, ensuring that each color meets stringent standards for quality and consistency.

SMART Colors™

SMART Colors curated selection of pre-developed colors is available in a versatile yarn size — 75 denier/72 filament draw textured yarn (DTY). These SMART Colors allow brands to accommodate quick production cycles and lower MCQs, ensuring greater adaptability to market demands.

“By locating roughly 10,000 color recipes and performing commercial trials in the L*a*b* color space, we can easily offer brands quick turns on possible matches for any custom color,” Murphy said. “There are many things to consider when using solution dyeing — it’s not a simple buy-sell proposition. Of course, through the entire process, we identify which color recipe may be the most sustainable, the best performing with regards to color fastness and consistency, the cheapest, and the recipe with the lowest working loss percentage in terms of lowest colorant dosing and highest strength in bulk yarn production.”

Sustainable, Trusted Solution

Brands often face a difficult dilemma with colorization — whether to adhere to a traditional water-dye technology or to seek a more sustainable path. The solution dyeing approach eliminates this com-promise by achieving both goals. By utilizing zero water during the yarn colorization process, reducing chemical usage, and lowering the carbon footprint, it offers an environmentally responsible alternative without sacrificing quality or performance.

To address any concerns that may arise, the process is backed by robust, third-party verification systems, including bluesign®, which certifies the chemical and yarn manufacturing stages. This transparency reinforces trust, enabling brands to confidently adopt a sustainable yet efficient model of textile colorization.

e.dye brand partners currently include Oslo-based clothing and sports equipment company Helly Hansen, Switzerland-based manufacturer of alpine sport clothing and equipment Mammut, Italy-based clothing company Paul & Shark Yachting and Sweden-based apparel company Oscar Jacobson.

Core Benefits of e.dye® Technology

According to Murphy, e.dye offers a variety of benefits to apparel manufacturers:

- Improved Color Performance: e.dye technology enhances colorfastness, ensuring colors retain their vibrancy and durability over time.

- Enhanced Consistency: By setting high standards for color matching with a target of DE 0.8 or under, e. dye drastically reduces inconsistencies. In contrast, traditional techniques often result in variances as high as DE 6.0, as noted during the 2024 AATCC Design Summit.

- Faster Color Development: Brands benefit from accelerated approval processes and development timelines, minimizing delays in production cycles.

- Sustainability: By offering a more environmentally friendly alternative to chemical dyeing, e.dye contributes to a better world, aligning with core values of ecological responsibility.

Financial Incentives, Costs

According to Murphy: “With effective strategic planning, clear core color alignment, and strong commitment, it’s possible to construct a compelling argument for enhancing inventory turnover by shortening development and production time-lines by up to 12 weeks.” These reduced lead times could translate into higher inventory turns and improved return on investment.

Sustainability directors with major brands and retailers often argue that there is no such thing as a “green tax.” Many believe that consumers are unwilling to pay a premium for sustainable textile products1. While this perspective is open to debate, the solution dye approach, when paired with an effective design and development strategy, can achieve cost parity or even lead to small cost savings. This approach is borne out by multiple deliveries to the world’s largest retailer, according to Murphy.

The e.dye process also helps reduce costs that are often overlooked on traditional fabric cost sheets. These reductions include expenses associated with maintaining global offices to audit dye house color-matching capabilities, lengthy color development timelines, four- to six-week colorization lead times, and losses resulting from returns due to inadequate color fastness. Additionally, poor color performance can harm brand reputation — an intangible, but critical cost.

Fundamental Question

A reasonable inquiry might be, “If this process enhances color performance and significantly reduces the environmental impact of textile colorization, why hasn’t it been universally adopted?”

According to Murphy, one major obstacle for any transformative shift is overcoming resistance within various brand functions — such as designers, colorists and textile developers — to adapt and rethink their established practices. “Current design and development workflows are deeply rooted in traditional colorization methods, which date back to the 1650s and rely on water, chemicals, and heat to color finished textiles,” Murphy noted.

In addition, this approach of course requires a transformation in process for fabric manufacturers. “It’s a paradigm shift in process thinking,” Murphy acknowledged. “The success of solution-dyed fabrics will require a strategic partnership between brand and supplier.

“But keep in mind that preposition in masterbatch color and yarn color requires color forecast and volume forecast ahead of time,” Murphy continued. “If these two forecasts are in place when a brand places an order with the sewing factory, then a fabric producer can immediately begin production and save six weeks that would be required for color samples and dyeing time.”

It’s also possible to use a yarn color in multiple fabric styles. “This requires a strategic plan of design to color to yarn in color to fabrics in color to commodity,” Murphy added. “In order to get the e.dye process adopted, we need to work across development ‘silos’ and get buy-in from a supply chain that is committed to sustainability.”

Future Outlook

Future Outlook

The company is currently collaborating with the NC State Wilson College of Textiles, Raleigh, N.C. e.dye is using the school’s extrusion lab to execute color trials for approval in the United States. The eventual goal is to establish a pilot facility in the United States for e.dye.

Another goal is to achieve scale, according to Murphy. “We need scale, not only to drive down costs but to move the needle as far as water, chemical and carbon dioxide savings are concerned,” he said. “Our objective is clear — ‘to make sustainability the easy choice’ as noted by Doug McMillon at the 2024 Walmart Sustainability Milestone Summit. For Walmart, and everyone else, that means a sustainable option cannot be more expensive. In fact, if we design the products and industrial processes correctly — using fewer energy inputs, for example — why can’t the sustainable solution also be the cheapest?”

Among e.dye’s strengths, Murphy notes the COLOR JOURNEY™. “Through our own captive SMAR-TEX textile converters located in China and Vietnam, e.dye has the capability to demonstrate to a brand the ‘journey’ color makes from color conception and design to yarn and textile creation right through to commodity production,” Murphy said. “If a brand cooperates, we can show them how to increase efficiency across what we call the yarn-color platform. We can build an intelligent, plan-full approach to color yarn and fabrics where transparency is the key.”

The e.dye solution-dyeing process embodies a paradigm shift in the textile industry, merging innovation, sustainability and performance. By addressing longstanding challenges in color matching, consistency, and environmental impact, e.dye equips brands with the tools they need to succeed in a competitive market.

With a vision for a better world, e.dye is working to redefine the possibilities of color technology.

2025 Quarterly Issue II