BADINERES, France — February 13, 2025 — Porcher Industries, a developer and producer of high-performance textiles and thermoplastic solutions, is proud to announce three major highlights that will be showcased at JEC World 2025. These solutions, designed to support all players in the composite value chain, showcase Porcher Industries’ commitment to advancing composite materials.

BADINERES, France — February 13, 2025 — Porcher Industries, a developer and producer of high-performance textiles and thermoplastic solutions, is proud to announce three major highlights that will be showcased at JEC World 2025. These solutions, designed to support all players in the composite value chain, showcase Porcher Industries’ commitment to advancing composite materials.

Launch of the Composite Application Lab (CAL)

Porcher Industries is unveiling its Composite Application Lab (CAL), a unique service designed to accelerate innovation in textiles and thermoplastic solutions. Acting as a true application laboratory, the CAL supports clients in creating tailor-made solutions.

Key objectives:

- Deliver innovative solutions leveraging expertise in technical materials.

- Develop prototypes and small production runs for enhanced responsiveness.

- Facilitate the transition to thermoplastic solutions with the “Vacuum Bag Only” process.

The CAL reflects Porcher Industries’ commitment to meeting its partners’ needs across all markets and applications.

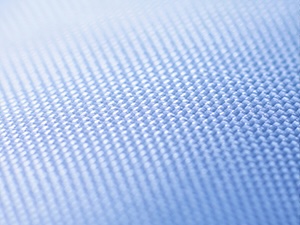

Porcher industries introduces its Peel Ply range for composite parts

A Peel Ply range designed to meet composite process requirements

Porcher Industries offers a line of peel ply textiles specifically engineered to optimize the manufacturing processes of composite parts.

Key features:

- Exceptional dimensional stability, ensuring a reliable manufacturing process.

- Easy removal, thanks to precise fabric tension management.

- Uniform weave, promoting strong and consistent bonding.

Targeted at demanding industries such as aerospace and industrial manufacturing, this range combines technical performance with ease of use, making it ideal for complex industrial processes.

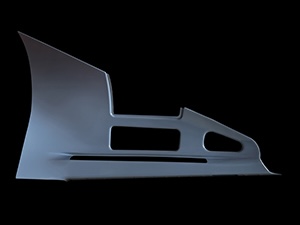

Aerospace Innovation: a revolutionary Cockpit

In collaboration with Airbus, Porcher Industries presents an innovative aerospace cockpit panel prototype made with materials optimized for vacuum bag consolidation:

- Material: Glass Fiber Reinforced Thermoplastic (GFRTP).

- Technology: Vacuum bag consolidation.

- Technical advantages: Simplified implementation:

Thinner material lightweight, and easy to assemble.

Manufacturing time savings: Opportunity to reduce the use of paints and varnishes, thanks to a naturally optimized surface.

Enhanced recyclability compared to traditional thermoset materials.

Once again, this technology showcases Porcher Industries’ ability to drive the adoption of composite materials.

Visit our booth 5U40 at JEC World from March 4–6, 2025, to discover these innovations! The cockpit is visible on our booth and on the JEC PLANETE MOBILITY

Posted: February 17, 2025

Source: Porcher Industries