NEUWIED, Germany — June 4, 2020 — Reacting to the worldwide shortage and peak demand for high quality lower cost face masks, the W+D/BICMA hygiene group of Winkler+Dünnebier has developed a fully automatic, high-speed face mask converting line for the production of high quality disposable face masks: Auxilium FM. This new converting line has a speed of up to 150 meters per minute (492 feet per minute) and is able to produce up to 1 million high quality face masks per day making it one of the fastest mask production machines in the world, according to the company.

NEUWIED, Germany — June 4, 2020 — Reacting to the worldwide shortage and peak demand for high quality lower cost face masks, the W+D/BICMA hygiene group of Winkler+Dünnebier has developed a fully automatic, high-speed face mask converting line for the production of high quality disposable face masks: Auxilium FM. This new converting line has a speed of up to 150 meters per minute (492 feet per minute) and is able to produce up to 1 million high quality face masks per day making it one of the fastest mask production machines in the world, according to the company.

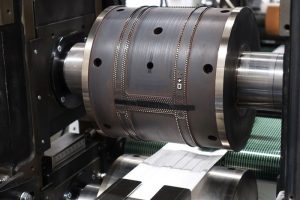

Adding to the manufacturing throughput efficiency of up to 800 face masks per minute is also a unique product concept, reducing the costs per piece by using for the ear loops standard materials which are common in the hygiene industry. The machine comes with CE sign and is suitable for Industry 4.0 applications. It can be equipped with various options such as fully automatic stacking, camera system for inline quality control, inline flexoprinting and many more.

The Auxilium FM mask line laminates and converts three or more layers of appropriate nonwoven materials (spunbond, meltblown, thermobonded or others). By converting suitable raw materials, producers may apply for EN 14683 I, II or IIR certification for masks they made on this quality machine. It combines W+D/Bicma’s proven technology in highspeed nonwoven processing with newly designed features like nose clip and earloop application.

The Auxilium FM mask line laminates and converts three or more layers of appropriate nonwoven materials (spunbond, meltblown, thermobonded or others). By converting suitable raw materials, producers may apply for EN 14683 I, II or IIR certification for masks they made on this quality machine. It combines W+D/Bicma’s proven technology in highspeed nonwoven processing with newly designed features like nose clip and earloop application.

Posted June 5, 2020

Source: Winkler+Dünnebier GmbH