Washington is a busy place. Every day, Congress and dozens of federal entities are making, implementing and enforcing policies on innumerable matters that affect U.S. textile jobs and trade. While some issues are broad and easy to understand, others are highly technical, if not arcane.

The National Council of Textile Organizations (NCTO) is structured into four governing councils — Fiber, Yarn, Fabric & Home Furnishings, and Industry Support — to help the U.S. textile supply chain form a consensus and speak with one voice on policy matters affecting the sector.

When the United States enacts new laws or federal agencies make administrative rule changes, some issues recur so often or are so complex that NCTO has formed special standing committees to complement its four-council structure. These committees inspire vibrant inter-council exchanges of expertise and ideas that enable member companies to better understand and influence policies affecting everything from cotton consumption to government procurement and flammability standards to customs rules. With technical input from all sectors of the supply chain, NCTO’s committees can vet policies even more rigorously than its councils. By harnessing expertise and fostering more robust policy deliberations, NCTO’s committee systems helps NCTO’s four councils make better-informed decisions, while serving as a unifying force for the U.S. textile industry. For more information on how NCTO’s four standing committees benefit the industry and consumers, check out the following profiles.

Government Textiles Committee: Encouraging Uncle Sam To Buy “Made In The USA”

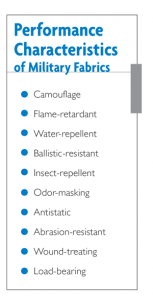

The single biggest customer for the U.S. textile and apparel supply chain is the U.S. government. The Department of Defense (DOD) alone purchases more than 8,000 different textile items for use by the U.S. military and other allied organizations, and this figure rises to more than 31,000 line items when individual sizes are factored into the item mix. Including DOD purchases, the U.S. government routinely spends more than $2 billion annually on textiles and clothing.

NCTO’s Government Textiles Committee, chaired by Nick Pence, director of Materials and Trims for Baltimore, Md.-based Under Armour, connects member companies from all points in the U.S. textile supply chain. Together, these companies oversee issues related to all facets of government procurement, including preservation and expansion of the Berry Amendment, contracting matters, and liaison with other organizations and government contracting agencies.

“As a U.S. Army Ranger, I know when equipment fails in action, lives can be endangered,” Pence said. “American-made military textiles and clothing are world-class. Knowing that gives warfighters added confidence going into a mission.

… America’s security depends on our military having guaranteed access to high-quality, innovative textile materials, apparel, and personal equipment made at home.”

Under the law known as the Berry Amendment (10 USC 2533a), most textiles and clothing purchased by the U.S. military are required to contain 100 percent U.S.-made fibers, yarns, and fabrics. Additionally, those textile and clothing goods must be cut and assembled in the United States.

In recent years, attempts have been made during consideration of the annual National Defense Authorization Act (NDAA) to weaken sourcing requirements for some products — including textiles, apparel, and footwear — covered under the Berry Amendment. NCTO has strongly opposed efforts to undermine the integrity of Berry and other “buy American” preference laws.

In recent years, attempts have been made during consideration of the annual National Defense Authorization Act (NDAA) to weaken sourcing requirements for some products — including textiles, apparel, and footwear — covered under the Berry Amendment. NCTO has strongly opposed efforts to undermine the integrity of Berry and other “buy American” preference laws.

Besides supporting domestic preferences, NCTO’s Government Textiles Committee works closely with the Defense Logistics Agency, the U.S. Army Natick Soldier Systems Center, Program Executive Office (PEO) Soldier and other entities to proactively anticipate the services’ future textile and clothing needs and develop the next generation of military textiles.

“Still, meeting those needs requires careful planning,” Pence said. “For example, if the services say they require 200,000 ballistic-resistant armor plate vests next year, someone must produce the fiber and/or yarn, weave the fabric, dye and finish the fabric, and finally cut and sew it before a finished product can be shipped to the troops.”

“NCTO wants to make sure upstream suppliers are making today what the military’s downstream customers will be needing tomorrow; if a key input is out of stock, production can be delayed for weeks,” Pence said.

NCTO also coordinated closely with the Department of Defense in organizing Advanced Functional Fabrics of America (AFFOA). This Cambridge, Massachusetts, innovation center managed by the Massachusetts Institute of Technology is tasked with developing next-generation textile fibers that can harvest energy, facilitate data transmission and more.

Upholstery Fabrics Committee: Showcasing Your Style, While Keeping You Safe

Lounging in your favorite recliner? Sporting a vibrant hue on your living room chairs? Curling up with a book on your favorite sofa? Upholstery fabrics not only showcase living spaces, they also must withstand the rigors of everyday use. In addition to abrasion resistance and repelling water and stains, upholstery fabrics also are made with fire safety in mind to protect their users.

Chaired by Michael Shelton, president and CEO, Valdese Weavers LLC, in Valdese, N.C., NCTO’s Upholstery Fabrics Committee oversees all upholstered furniture flammability issues at federal and state levels. It also addresses performance standards, chemical regulations, intellectual property rights and other matters affecting the upholstery fabrics industry sector.

“The Upholstery Fabrics Committee has had a full plate in recent years,” Shelton said. “Tracking flammability standards and ensuring that they are reasonable, effective, realistic and affordable is a large part of the work of our committee.”

The committee also works to help make sure fabrics meet consumer expectations, which include strength and colorfastness, as well as protection from accidental spills such as coffee, ketchup and mustard. Spill protection is achieved using finishes that repel dirt, water and oily substances, and the latest generation of performance fabric finishes are the result of numerous technical advancements that meet regulatory standards designed to protect health and the environment.

The committee also has filed public comments with the United States Trade Representative about imported upholstery fabrics, particularly certain products from China, that violate copyright laws and infringe on intellectual property protections in the United States.

“What sets American upholstery manufacturers apart is our proven track record of continually producing new fabrics with the most fashionable colors and designs anywhere in the world,” Shelton said. “But if overseas competitors can illegally knock off the product, U.S. manufacturers are denied the rewards of their unique styling and design, research and development, disincentivizing domestic investment. That’s why the Upholstery Fabrics Committee has been fighting so hard to make sure U.S. Customs and American courts rigorously enforce intellectual property rights.”

Cotton Committee: Influencing Policy From Farm To Fabric

The most commonly used natural fiber in textiles is cotton, a highly preferred fiber choice for jeans, shirts, bedding and other products because it is soft, absorbent, breathable and does not retain odors.

According to the National Cotton Council of America (NCC), U.S. farmers grew 20.9 million bales of cotton in 2017. Net domestic consumption of the fiber totaled an estimated 17.7 million bales, including 3.2 million bales by domestic yarn spinners.

“NCTO’s Cotton Committee brings together cooperatives, brokers, shippers, yarn spinners, and fabric knitters and weavers to oversee all policy matters pertaining to the cotton textile supply chain,” said Cotton Committee chairman Anderson D. Warlick, chairman and CEO of Gastonia, N.C.-based Parkdale.

These issues include the Farm Bill, fiber quality, contamination, manufacturing, trade agreements, and relations with U.S. Department of Agriculture and cotton organizations like the NCC and the American Cotton Shippers Association. “The Farm Bill is especially important,” Warlick said.

Normally passed by Congress every five years, the Farm Bill sets policy impacting the prices of all farm commodities. Whenever the bill comes up for reauthorization, NCTO’s Cotton Committee teams with NCC to press for common sense provisions to ensure there is consistent availability and steady consumption of U.S. cotton, while balancing the interests of cotton manufacturers.

“Since government-influenced commodity prices affect the competitiveness of cotton-consuming mills, it is imperative that the Farm Bill benefits both farmers and the domestic textile supply chain,” Warlick emphasized as he explained the importance of maintaining productive working relationships with policymakers in Washington, D.C. on cotton issues.

“When you combine world-class farmers, a good Farm Bill, efficient looms, and cheap, reliable utilities, U.S. cotton yarn spinners can compete with anyone in the world and that’s why NCTO’s Cotton Committee works hard to make sure U.S. policy reflects that position.”

Regulatory & Standards Committee: Helping Textile Companies Run Safely & Smoothly

Businesses must comply with a host of regulations and standards on everything from health and safety to customs reporting and recordkeeping.

Chaired by Jim Booterbaugh, CEO of Washington, N.C.-based National Spinning Co. Inc., NCTO’s Regulatory and Standards Committee works to ensure that U.S. textile companies can run their operations safely and smoothly.

“NCTO members recognize the necessity of regulation, but regulations must be well-defined, quantifiable, realistic and affordable,” said Booterbaugh.

“A poorly crafted workplace or environmental regulatory regime can drive entire industrial sectors offshore,” he added.

With California taking the lead, many states have adopted or are looking at adopting chemical regulations more stringent than those of the federal government.

“A multiplicity of standards creates havoc when you have a nationally distributed product,” said Booterbaugh.

“The need for safety is unquestioned,” Booterbaugh continued. “The Regulatory & Standards Committee works on behalf of NCTO members to make sure regulations are written in a common sense way that makes them readily understandable and realistic to comply with.”

Because most regulatory matters are complex, the Regulatory and Standards Committee works with other trade associations to address issues collectively.

“The best way to get a regulation that benefits all Americans is to work across industry lines,” Booterbaugh said. “One day you’ll be working with the chemical industry and the next with a consumer advocacy group.”

Other areas where NCTO tries to coordinate with others include occupational safety and health matters, (OSHA) and motor freight regulations to encourage the safe and reasonable transport of products.

Finally, NCTO also liaises closely with ASTM International and the American Association of Textile Chemists and Colorists (AATCC) to establish test methods for textile abrasion, tensile and tearing strength, and wet processing methods like water repellency, among other performance attributes.

“In practice, the only way to make sure a product performs in the field the same way it was designed to do on the drawing board is to test it,” Booterbaugh said. “While testing can be expensive and time consuming, it ensures textile companies will be able to market performance benefits to the consumer with confidence derived from rigorous scientific data.”

Editor’s Note: This article appears in Textile World courtesy of the National Council of Textile Organizations (NCTO) as part of the “American Textiles: We Make Amazing™” campaign. NCTO is a trade association representing U.S. textile manufacturing. Please visit ncto.org to learn more about NCTO, the industry and the campaign.

September/October 2019