The combination of strong design competence and cutting-edge cellulose-based technologies can

result in new commercially successful brands. The aim is for fibre from wood-based biomass to

replace both cotton production, which burdens the environment, and polyester production, which

consumes oil. A research project launched by VTT Technical Research Centre of Finland, Aalto

University and Tampere University of Technology aims to create new business models and ecosystems

in Finland through design-driven cellulose products.

The joint research project is called Design Driven Value Chains in the World of Cellulose

(DWoC). The objective is to develop cellulose-based products suitable for technical textiles and

consumer products. The technology could also find use in the pharmaceutical, food and automotive

industries. Another objective is to build a new business ecosystem and promote spin-offs.

The breakthrough for these new products and services is expected to take a few years.

State-of-the-art cellulose processing technologies could generate production value of up to EUR 2-3

billion in Finland’s forestry, textile and mechanical engineering industries, and in entirely new

business sectors.

This is one of two strategic projects launched by Tekes – Finnish Funding Agency for

Technology and Innovation intended to help transform Finnish business life. The project received

nearly EUR 3 million in funding from Tekes for the opening research stages in 2013-2015.

Designers Envision Consumer Products Of The Future

Aalto University students participate in the project by offering fresh new perspectives on

Finnish cellulose products.

“The research project provides an opportunity to use design methods to turn cellulose raw

material into products, services and business. Designers contribute to the project by introducing

an experimental method of creating prototypes, as well as the ability to visualise something that

doesn’t yet exist. This allows us to take consumer perspective into account at different stages of

the programme,” explains Professor Pirjo Kääriäinen from the Aalto University’s Department of

Design.

According to Kääriäinen, design as a strategic resource in the industry is so far relatively

untapped. As a working method, industrial design brings a user-focused perspective to the project,

opening new and unexplored opportunities for commercial use of the materials and for envisioning

new products. This work combines with the creation of business ecosystems in line with the

principles of sustainable development.

New materials and technologies are a source of inspiration to designers. The first sessions

with technology developers were filled with excitement and bursts of innovation. For researchers,

the notion of design needs affecting the material being created was particularly interesting.

New Technologies In Yarn Manufacture

Researchers seek to combine Finnish design competence with cutting-edge technological

developments to utilise the special characteristics of cellulose to create products that feature

the best qualities of materials such as cotton and polyester. Product characteristics achieved by

using new manufacturing technologies and nanocellulose as a structural fibre element include

recyclability and individual production.

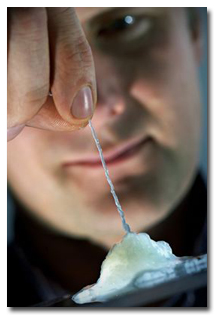

The first tests performed by professor Olli Ilkkala’s team at the Aalto University showed

that the self-assembly of cellulose fibrils in wood permits the fibrils to be spun into strong

yarn.

VTT has developed an industrial process that produces yarn from cellulose fibres without the

spinning process. VTT has also developed efficient applications of the foam forming method for

manufacturing materials that resemble fabric.

“In the future, combining different methods will enable production of individual fibre

structures and textile products, even by using 3D printing technology,” says Professor Ali Harlin

from VTT.

Usually the price of a textile product is the key criterion even though produced sustainably.

New methods help significantly to shorten the manufacturing chain of existing textile products and

bring it closer to consumers to respond to their rapidly changing needs. Projects are currently

under way where the objective is to replace wet spinning with extrusion technology. The purpose is

to develop fabric manufacturing methods where several stages of weaving and knitting are replaced

without losing the key characteristics of the textile, such as the way it hangs.

Finland’s Logging Residue To Replace Environmentally Detrimental Cotton

Cotton textiles account for about 40% of the world’s textile markets, and oil-based polyester

for practically the remainder. Cellulose-based fibres make up 6% of the market. Although cotton is

durable and comfortable to wear, cotton production is highly water-intensive, and artificial

fertilisers and chemical pesticides are often needed to ensure a good crop. The surface area of

cotton-growing regions globally equates to the size of Finland.

Approximately 5-6 million tons of fibre could be manufactured from Finland’s current logging

residue (25-30 million cubic metres/year). This could replace more than 20% of globally produced

cotton, at the same time reducing carbon dioxide emissions by 120-150 million tons, and releasing

enough farming land to grow food for 18-25 million people. Desertification would also decrease by

approximately 10 per cent.

Posted October 8, 2013

Source: VTT Technical Research Centre of Finland