Among the member associations of the European Committee of Textile Machinery Manufacturers

(CEMATEX), the German Engineering Federation (VDMA) Textile Machinery Association is by far the

biggest.

Around 120 of the most important manufacturers of textile machinery and accessories from all

sectors of the trade are affiliated within VDMA. The largest portion of the companies comprises

medium-sized companies, which represent approximately 90 percent of the entire sector volume. In

2012, the branch exported textile machinery worth about 3.1 billion euros. It seems that 2013 will

be an even better year for the German manufacturers.

Different Success Rates For Different Sectors

Exports, as everywhere in Europe, are playing a major role for the success of a textile

machinery association. VDMA is running representative offices in Brazil, China and India, to be

close to the customers in major South American and Asian markets. The offices serve as hubs between

German and Brazilian, Chinese and Indian companies and associations as well as authorities.

During a recent visit to Frankfurt, the Rupp Report had the opportunity to talk to Nicolai

Strauch, public relations officer for VDMA’s Textile Machinery Association, about facts and figures

pertaining to its members. He gave detailed information for the period of January through July

2013:

For spinning machines, compared to an export volume of 781.359 million euros in the same

period of 2012, the current period in 2013 netted 821.575 million euros. A slightly negative

development is shown with weaving machines: here, last year’s volume was 123.500 million euros, and

for 2013, it dropped to 116.721 million euros from January through July.

However, for knitting machines, VDMA reports a slight increase: compared to 452.610 million

euros in 2012, the first seven months in 2013 record a volume of 471.371 million euros. The

finishing machinery sector recorded the sharpest drop in volume: from 473.174 million euros in 2012

to 406.735 million euros in the same period in 2013.

Sharp Slowdown In China

The somewhat negative picture — which, in fact, is a positive — is mainly caused by the

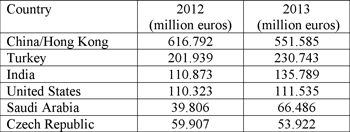

declining business in China. The following interesting table shows the development of German

textile machinery exports to the most important countries over a period from January to July for

2012 and 2013:

Turkey, India, the United States and Saudi Arabia show higher export volumes, with an overall

big jump in 2013. From January through July 2013, German textile machinery and accessories worth

1.8 billion euros have been exported.

Taking a closer look at the major destinations shows that China weakened in the first half of

this year. Shipping of German textile machinery and accessories to China decreased by 11 percent

year-on-year and reached approximately 552 million Euros. The exports to Turkey, a market that

already performed very well in 2012, increased again — by 14 percent to approximately 231 million

euros.

India Is Back

But also the Indian textile industry strikes back: After two weak years, the sector invested

much more during the first half of 2013, which resulted in German deliveries worth 136 million

euros — an increase of nearly 23 percent. And a former established textile nation is celebrating a

kind of comeback: the United States. The Rupp Report has already informed its readers about the

comeback of the U.S. textile industry some months ago

(See ”

The

Rupp Report: Astonishing Investment Climate In The U.S.,”

TextileWorld.com, May 14, 2013). While the overall German textile machinery

exports to the U.S. — worth more than 111 million euros in the 2013 period — is just a small

increase, the shipping of spinning machinery nearly doubled year-on-year.

Positive Outlook

Strauch added that the latest incoming orders figures for the German textile machinery

industry increased by an encouraging 18 percent between January and August 2013 compared to the

respective period in 2012. “The high expectations of the VDMA member companies towards the export

performance indicate good business for the next months,” he said. And to end an interesting meeting

positively, he commented, “Regarding the good performance in this year, the VDMA sales forecast of

an increase of some 5 percent for 2013 proved to be realistic.” That is a promise for the future.

October 15, 2013