OBERTSHAUSEN, Germany — May 8, 2024 — The KARL MAYER GROUP looks back on a successful Techtextil. At the industry’s trade fair in Frankfurt am Main in April, the global player once again presented itself as a competent partner to the Technical Textiles sector, with solutions for mastering the challenges of our time in the areas of Warp Knitting, Flat Knitting, Composites, Warp Preparation, Digitization and Care Solutions.

OBERTSHAUSEN, Germany — May 8, 2024 — The KARL MAYER GROUP looks back on a successful Techtextil. At the industry’s trade fair in Frankfurt am Main in April, the global player once again presented itself as a competent partner to the Technical Textiles sector, with solutions for mastering the challenges of our time in the areas of Warp Knitting, Flat Knitting, Composites, Warp Preparation, Digitization and Care Solutions.

The exhibition with its strong market focus was very well received. The KARL MAYER GROUP counted around 380 registered visitors at its stand, and a further 76 customers travelled to the headquarters in Obertshausen to see the latest representatives of the tricot machine and RASCHELTRONIC® series “at work” at an in-house show. Most of the visitors came from Europe, with Germany at the top of the list of countries of origin. Some traveled from the United States, India, Turkey and the United Kingdom. Around 32 percent of the guests came to talk to the group of companies for the first time, a pleasingly high proportion of new contacts!

The exhibition with its strong market focus was very well received. The KARL MAYER GROUP counted around 380 registered visitors at its stand, and a further 76 customers travelled to the headquarters in Obertshausen to see the latest representatives of the tricot machine and RASCHELTRONIC® series “at work” at an in-house show. Most of the visitors came from Europe, with Germany at the top of the list of countries of origin. Some traveled from the United States, India, Turkey and the United Kingdom. Around 32 percent of the guests came to talk to the group of companies for the first time, a pleasingly high proportion of new contacts!

The number of visitors remained almost constant compared to Techtextil 2022, but the quality of the conversations had increased significantly, according to the almost unanimous feedback from the trade fair team. During the joint exchange, the implementation possibilities of ideas were discussed as well as specific machine projects and the application potential of KARL MAYER warp knitting and STOLL knitting machine products.

Many specific inquiries also came from the composites industry regarding multiaxial warp knitting machines and warp knitting machines with weft insertion.

“We have held a number of discussions, on the basis of which we see realistic opportunities for projects in the coming months,” said Hagen Lotzmann, sales manager of the Technical Textiles Business Unit.

Other key topics of discussion were KM.ON’s digital solutions, Care Solutions’ offerings and the possibilities offered by KARL MAYER warp preparation machines for generating new business or expanding capacity.

What is hot in the sector?

In addition to a showcase of innovations, Techtextil always offers the opportunity to track down trends in the industry. “You can sense a spirit of optimism. Manufacturers from fashion to automotive are on the lookout for real innovations. Brands in particular are showing a great willingness to invest in product innovations,” concluded Michael Kieren from the Business Development department at KARL MAYER.

Products with signpost qualities

Truly new means unprecedented in terms of surfaces, structures and function, especially through the integration of conductive or luminous material into the textile, new laminates, for example with an artificial leather look and feel, and 3D printing. Under TEXTILE CIRCUIT, KARL MAYER is developing innovations with conductive yarns incorporated directly on the warp knitting machine. There were many discussions about this. Traditionally, spacer fabrics also play an important role in functionalization. They are already firmly established in applications involving upholstery and ventilation, but their wide range of design options means that they also offer far-reaching potential applications. As a result, the universally applicable spacers were almost on everyone’s lips at Techtextil 2024.

The new Flex Ply technology sets standards in the flat knitting sector. At Techtextil, a series of application examples from the shoe upper, upholstery and clothing fabric sectors demonstrated the unique patterning and fabric design options that are possible thanks to this innovation. In addition, the innovative bonding of hot-melt adhesive yarns opens up interesting possibilities for functional solutions, particularly in terms of reinforcement.

Sustainable solutions

Another important topic is sustainability. In particular, the use of recycled materials and resource-saving production are in demand. The preformed knitted fabrics from STOLL machines can set standards here, especially as reinforcements for composites. They can be produced individually, according to the application and therefore without a lot of waste and from a wide variety of materials and were the focus of many discussions, both from established brands and young start-ups. Seamless knitted medical products with a compression effect offer the same benefits as well as comfort without any irritating seams. They are produced in one piece and are therefore highly efficient, also in terms of material usage. “The seamless compression technology represents an innovative and forward-looking production method that will find its way into production plants in the coming years,” said Martin Legner, STOLL head of Technical Textiles.

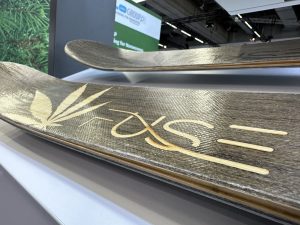

The composites industry is also on the lookout for sustainable solutions. Accordingly, there was great interest in the ski made of hemp tapes, which was an eye-catcher at the KARL MAYER GROUP stand and also brought many new interested parties into conversation with the company’s experts.

The composites industry is also on the lookout for sustainable solutions. Accordingly, there was great interest in the ski made of hemp tapes, which was an eye-catcher at the KARL MAYER GROUP stand and also brought many new interested parties into conversation with the company’s experts.

Textiles for defense

A new trend theme at Techtextil was defense, in line with the global situation. Exhibits in camouflage look — from uniforms, camouflage nets and tarpaulins to protection vests – accompanied visitors at every turn at Techtextil. Warp knitting is also well established in this sector. Nets, for example, are the domain of Raschel machines, especially in the agricultural sector, and spacer fabrics provide comfort as padding in helmets, rucksacks and protective equipment.

The knitting sector produces clothing and underwear components based on high-modulus fibers.

Posted: May 8, 2024

Source: KARL MAYER GROUP