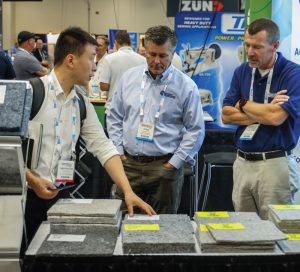

Professionals in the home furnishings industry have the opportunity to learn and network at the upcoming expo.

Professionals in the home furnishings industry have the opportunity to learn and network at the upcoming expo.

TW Special Report

The Furniture Manufacturing Expo returns to the Hickory Metro Convention Center in Hickory, N.C., July 19-20, 2023. The event gathers suppliers of solutions — including equipment and machinery, services, technology, warehousing, and financial and logistics services —for manufacturers and importers of home furnishings.

The show is targeted to professionals involved in the manufacturing of home furnishings including designers, engineers, executives, machine operators, plant managers, procurement officers, purchasing managers, quality control managers, research and development managers, and specifiers.

Furniture Manufacturing Expo is owned by Exposition Development Co. Inc. (ExpoDevCo).

Exhibitor Product Groups

Exhibitor Product Groups

The exhibitors are organized by groups as follows: Computer Software/Information Technology; Contract Manufacturing; Cutting & Sewing Equipment; Distributors; Fabrics; Fibers; Financial Management; Findings/Trims; Foam; Adhesives/Finishes/Paints; Foam Fabricating Machinery; Furniture Manufacturing Machinery; Hard-ware & Components; Nonwovens; Packaging; Quilting Machinery; Racking Systems; Research & Development; Services & Logistics; Sup-plies; Testing Equipment; Testing Laboratories; Upholstery Mechanisms; Wood Process Machinery; Yarns; Assocations; and Publications.

“This year will be the largest Furniture Manufacturing Expo since the show was launched in 2017,” said Lorie Gross, show director. “Attendees will discover a record number of exhibitors including new companies from Brazil, China, Italy, and Turkey, as well as a broader selection of educational programs offering sessions dedicated to upholstery and woodworking.”

New Feature: Micro Plant

New Feature: Micro Plant

The Micro Plant is a new show feature that will debut in July. This interactive exhibit — a concept conceived by sponsor Zund America— guides visitors around the show floor on a marked path to view each step in the process of constructing a chair (see sidebar).

“Zund reached out to us over a year ago with the Micro Plant idea,” Gross said. “They wanted to create a step-by-step journey around the show floor that would let attendees experience each phase of constructing a chair and give them the opportunity to see, touch, and ask questions along the way. This is an excellent add on value feature for our attendees.”

Education

Education

The Furniture Manufacturing Expo also will offer visitors a chance to participate in symposium sessions arranged in three tracks — Woodworking, Upholstery I and Upholstery II. A variety of experts will give presentations over the two-day event covering topics including automation, sewing and fabric matching, among other topics. See Table 1 for the topics and times for the symposium sessions.

Micro Plant Debuts At 2023 Furniture Manufacturing Expo

Micro Plant Debuts At 2023 Furniture Manufacturing Expo

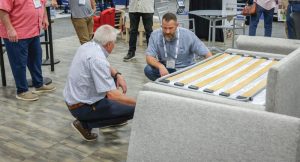

The Micro Plant is a brand-new feature at the 2023 Furniture Manufacturing Expo. Exhibiting sponsors and supporters will come together to illustrate each step in the manufacturing process for an upholstered chair. Show attendees will be guided around the show floor to walk through the eight-step process that culminates in the assembly of a completed chair.

Exhibiting sponsors include BEA Fasteners, Crest Leather, Fil-Tec, Henderson Sewing Machine Co., Hickory Springs, National Upholstery Association, Quis Machinery, Domenick’s Furniture Manufacturer and Zund America; and exhibiting supporters

are Lee’s Decorative Showcase/DADS Nails, and Leggett & Platt.

On the last day of the show, two chairs produced during the expo will be auctioned with proceeds going to a local organization dedicated to the furniture manufacturing industry.

“Going to tradeshows is often an experience that gives you a view of so many trees, but very little forest,” said Bill Richards, sales director at Zund America. “The Micro Plant is based on a more holistic approach. We are excited at this opportunity to work with our fellow exhibitors to show how all the different components — including Zund digital cutting solutions — fit together in the process of state-of-the-art furniture manufacturing.”

Textile World recently had the opportunity to ask Richards a few questions about the Micro Plant.

TW: What was the idea behind the Micro Plant?

Richards: The idea behind the Micro Plant is to give attendees to the Furniture Manufacturing Expo insight to the steps involved in the manufacturing process of a quality piece of furniture. The insight will come from an interactive, guided tour throughout the show to the different booths of the fellow sponsors of the Micro Plant to share a detail of their piece of the journey of the furniture from start to completion.

TW: How were the companies chosen to participate?

Richards: The companies chosen to participate in the Micro Plant all play a critical role in the process. Let’s face it, without the pieces, the final product is impossible to finish. From materials like frame, foam, leather and hardware to process like sewing, cutting, assembly and covering, the Micro Plant will walk attendees through each step in the process.

TW: What do you hope visitors to the show learn from the Micro Plant?

Richards: I really hope attendees will develop a better understanding of complexities of the furniture manufacturing process but also see, with the quality components and efficient process, manufacturing in the United States is not only possible but can be profitable for businesses.

TW: Are any interesting technologies features in the Micro Plant?

Richards: Every step of the Micro Plant tour will offer an interesting technology including the frame machining from Quis and the high-speed sewing with Henderson Sewing. The technology I am the most excited about though is the digital cutting process provided by Zund America. Our cutting system can digitally scan the leather hide from Crest Leather, respect any natural flaws in the hide material, efficiently nest the cover pieces around those flaws to maximize hide yield. Once cutting completes, the cut parts are automatically conveyed onto our extension table where an ultra-bright 4K projector will color the cut parts based on predetermined assignments for quick and accurate picking and kitting of the parts for future process downstream like sewing. Accurately, fast, efficient and with high yields.

For more information about the Furniture Manufacturing Expo, please visit furnituremanufacturingexpo.com.

May/June 2023