Past fiber development may suggest the future for fibers.

By Jeff Dugan

To loosely quote Marcus Aurelius, “Looking back over the past, one can foresee the future.” This same idea applies to fiber research and development. For insight on where fiber developments might go in the future, the best indicator is the past. There is no crystal ball and no way to truly predict the future, only a “guess-o-meter.” But the past suggests possible future direction. Some developments are more near-term and less of a leap of faith, while some other developments are longer-term projects that may or may not come to fruition.

The distance between a great idea and commercialization is very long and unfortunately there is a lot of opportunity for things to go wrong. Sometimes, the greatest ideas just don’t pan out.

If we compare the fiber industry of today to that of 20 to 30 years ago, not much has changed. Today, polyester is still king and poly/cotton blends are still woven and knit into fabrics. Some 20 to 30 years ago, perhaps people thought everyone would be wearing nonwovens in a few decades and that hasn’t happened yet, although it still eventually could. Obviously, research and development is ongoing and things that are in development today will change the face of the industry in the next few decades. But it’s important to remember that change is slow and in probably the next 20 to 30 years things that are important now are still going to be important in the fiber industry.

Also, the big developments that have taken place have mostly been on the margins. If history is a straight line — and of course it never is — but if the future is like the past, then the margins are where most of the new developments will remain.

If that’s the case, then why focus on those innovations? The answer is because that’s where the money is. Even if a company is working on a development that is going to remain in the margins, it’s where producers can make money instead of competing solely on price and volume. It’s one of the reasons why companies chase innovations and new developments.

There also is always the dream that not only can research create something that is profitable, but perhaps it will result in a “new polyester” that fundamentally changes the industry. Polyester has been king for decades, but it didn’t exist 100 years ago, and change will happen eventually.

Bicomponent Fibers

Bicomponent fibers are not new, but one of the still untapped uses is in binder fiber applications. There is new technology coming online that will allow for expanded performance of binder fibers. People are fairly familiar with standard binder fibers. With new polymer developments, there are new melt temperatures available to tailor the fiber to the application. The ability to chose between an amorphous or a crystalline binder also can better tailor a product to do the job that’s needed.

In addition, one newer possibility is a binder that will bond the fabric together initially and then at whatever time is needed for the application, the bonds may be released. Those are potentially near-term possibilities in binder fiber innovations.

Taggant technologies are another currently available bicomponent technology that is underutilized and there is a lot of value in these type of fiber technologies. An identifier like a 2D barcode can be created, or materials can be used that light up the fiber when viewed using different wavelengths of light.

A 2D barcode provides a lot of information where forensic approach of sorts is required to determine the cross section and extract the information in the barcode. In comparison, a tag that is revealed using a certain wavelength of light is more of a simplistic, binary technology that only identifies the fiber if it’s present. There’s not a whole lot of information in this type of tag, but it can be useful in certain applications such as a point-of-sale scan.

It’s possible in the future some sort of taggant technologies may be required in order to have downstream accountability. Such applications offer a way to extend bicomponent technology beyond where it is today.

Using a DNA additive is a newer approach to these taggant technologies. DNA can be inserted into a fiber now that contains a lot of information similar to the 2D barcode. One advantage of using DNA is extracting the information is more straightforward and forensic methods aren’t necessary. This technology is not cheaper, but a more straightforward way of embedding lots of information into a fiber.

Beyond taggants, splittable fibers also offer some expansion possibilities for bicomponent fibers in the market. When producing spun yarns, microfibers pose a problem in the carding machine. However, with control of the cross section of a bicomponent fiber, the splittability of the fiber also can be controlled, which offers a way to incorporate microfibers into spun yarns. The splittability property is important because carding processes are all different, and the design and application may require a different mix of splittable microfibers and non-microfibers. With all of the different cross sections that can be produced in combination with the many different types of polymers available, it is possible to manufacture a really broad range of splittable fiber.

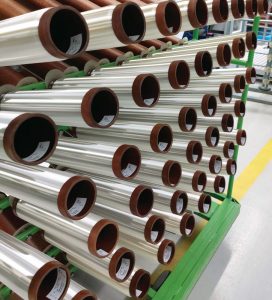

Cardable, splittable bicomponent fibers include (See Figure 1):

- Hollow;

- Hollow partial wrap;

- Standard;

- Standard partial wrap; and

- Hollow full wrap.

With a range of splittabilities, it’s possible to tailor a fiber to a process and card a blend where the bicomponent fibers split during carding. The caveat is that there has to be some non-splittable, non-microfibers in the fiber mix to carry all the fiber through the process. But this technique allows microfibers to be blended in spun yarns. This expansion of bicomponent fiber applications may require some additional downstream work, but it’s a fairly low hanging fruit that is available and ripe for development in the short-term.

Environmentally Advantaged Fibers

Another short-term development on the fiber future “guess-o-meter” is environmentally advantaged fibers. The term “green” fiber can mean many different things, and there is much more to “green” fibers than just sustainability or carbon dioxide mitigation including microplastic concerns, toxicity and landfill issues. Different fiber technologies address different environmental concerns and the term environmentally advantaged is a fitting term to use to cover many scenarios.

One of the first things that is already underway is an expanding role for natural fibers. It’s clear from a consumer’s point of view that these fibers are greener than a plastic. However, despite demand, natural fibers are not 100-percent of what is used in textiles because they don’t deliver the properties that polyester in particular delivers.

For use of natural fibers to expand much more than it has already, there may need to be some work done to chemically modify the fibers to expand their property envelope. Also, at some point in the future, there will be a debate about whether to use our land to produce something that isn’t food. Producers of polylactic acid (PLA) fibers already have seen some push back on the polymer because they are using corn and are therefore consuming some of the food supply. So, the expansion of natural fibers may hinge on the question “fibers or food?” Ultimately the battle — if it is even a battle — between natural and synthetic fibers is going to be one that is potentially limited by the evolution of plastics. There is a lot of work taking place in the plastics industry to address some of the environmental problems that plastics present, and solutions are becoming compelling. Not many of the solutions are cost effective yet, but at least technologically there are a lot of answers to environmental issues. The speed of development and the ultimate cost of new solutions may very well may limit the impetus to focus more on natural fibers.

One newer technology developed in the plastics industry that delivers a lot of bang for the buck is degradation enhancing additives (DEAs). CiCLO® is one such technology offered by Intrinsic Advanced Materials, a joint venture between Intrinsic Textiles Group and Parkdale Advanced Materials. There are other technologies in the market, and they work in basically the same way. When DEAs are added to just about any plastic, the material will degrade in a microbe-rich environment in two to three years and not in 200 or 300 years.

One of the appealing things about these technologies is the relative low cost compared to biopolymers, which are often sought after to solve environmental issues. Biopolymers offer a lot of technical advantages, but none of them is cheap. DEAs are relatively low cost and can be put into a product right away. Another big advantage is that biopolymers require a significant sacrifice in properties in the application or processing, or both. DEAs allow an environmental benefit at low cost, quickly with essentially no sacrifice in properties. In addition, some biopolymers require composting to degrade, and DEAs allow a fiber to degrade in any microbe-rich environment without requiring composting.

One drawback is that the degradation may not occur as fast as it does in some of the other polymers such as PLA. But there is a compelling proposition for the use of DEAs when comparing a product that degrades quickly but is expensive and costs a lot in terms of properties versus a fiber with DEAs that doesn’t degrade right away, but degrades in a couple of years versus centuries and the technology exists today. DEAs likely will become an important technology in a fairly short amount of time.

Polyethylene furanoate (PEF) is a new biopolymer being developed primarily by Avantium in the Netherlands, among other companies. PEF is an exception in the biopolymer world because choosing biobased ingredients does not mean sacrificing fiber properties as it does with other biopolymers.

Fully biobased polyethylene terephthalate (PET) is not yet a reality because biobased ethylene is an available feedstock, but the terephthalate part is really tricky. In PEF, the furanoate monomer — 2,5-furandicaboxylic acid — combines with biobased ethylene glycol to make a polymer that is very similar to PET, but the furanoate monomer also is biobased so the resulting PEF polymer is 100-percent biobased. The fiber has some natural degradability, but is not spontaneously biodegradable, which is useful because many applications require durability. PEF is inbetween the two extremes — it doesn’t degrade right away, but it can be made to degrade if necessary. The fiber properties are comparable to polyester, but the fiber is biodegradable in the medium-term and may be recycled in typical PET recycling streams, which is a significant advantage. Another upside is that PEF may be produced in an existing PET plant. The reaction kinetics are different, but fundamentally, manufacturers just need to swap the terephthalate monomer for the furanoate monomer. In addition, PEF in particular would be a good polymer to use in combination with DEAs.

One drawback to PEF is its cost. This is due in part to the fact that it’s early in the development stage, so the price will come down. Avantium has shared projections for the cost, and it is predicting that with scale the price will be comparable to PLA, maybe a little higher. But that is a significant premium, which has frankly hampered the adoption of PLA in mass markets.

On the price front, there are other reasons to believe the cost will get to an acceptable level. Some research is taking place to develop a polymerization process that may cut the cost of making PEF to about 20 percent of what it is now. In addition, the oxygen barrier of PEF is fantastic. This property means nothing in fibers, but is very important in the plastic bottle market. Coca-Cola, among other companies, is investing a lot of money to develop bioplastic bottles, which will drive the development of PEF.

The other option is to make a 100-percent biodegradable PET, which can be done, but it’s expensive and despite large investments that nut has not yet been cracked. And with the property differences in mind, PEF has a chance to be the winner over biodegradable polyester. If it is, the volumes will be enormous and the cost will be driven down. PEF is a fiber to watch. The research is not quite there yet, but the first pilot scale plant is in the works.

Polyhydroxy alkanoates (PHAs) is another class of biopolymers that bears watching. They are still not quite ready for prime time as a textile fiber, but the technology is getting closer to commercialization. PHAs have many advantages over some other materials. They are 100-percent biobased and are spontaneously biodegradable. As previously mentioned, it’s an advantage that PEF has some durability to it — that’s something that will be desired in many applications. But there are other applications where spontaneous degradability is important. Anywhere there are microbes, PHAs will degrade. That doesn’t mean it will degrade hanging in the closet. But when left on the ground, degradation is quick; and the polymer is also marine degradable, which makes it a promising solution to the marine plastics and microplastics issues. PHAs are likely to be available at relatively low cost at scale — possibly even cheaper than polypropylene, which is a tremendous advantage over other biopolymers. PHAs also can be made from just about any biomaterial or carbon dioxide so sugars from corn or other food sources are not impacted. Factories can even use carbon dioxide captured by a scrubber on a smokestack as the raw material for a PHA — how green is that? PHAs are not quite there yet in terms of processability, but this is chemistry base that has wide tailorability. There are many ways to tailor the properties of the polymer, and this, plus the compelling environmental advantages, will hopefully drive development forward to a solution.

Chemical recycling also is potentially a big deal in the environmentally advantaged fibers category. Years ago, BASF looked into depolymerizing nylon. Back then, it wasn’t an environmental issue, it was more cost-driven research, but the company determined it was cost prohibitive. It’s interesting to see renewed activity in this area today. Polyester and polypropylene recycling plants are being built many places in the world now, and it’s hard to imagine that kind of capital would be invested unless it was going to be a profitable endeavor.

Chemical recycling also eliminates downcycling so conceivably a polyester can be recycled eternally.

There is a debate about recycling versus using biopolymers because recycling seems so simple — it’s just a mechanical process — and biopolymers seem more exotic and advantageous. But in terms of delivering an environmental advantage, recycling, in the right context, can be more powerful than a polymer that easily degrades. In the future, there will be a lot more focus on chemical recycling efforts.

Electrical Applications

There are things that can be done with fibers and textiles that haven’t been adequately developed yet, including electrical applications. Electrically functional apparel — adding wires to textiles — has been in development for some time, but it hasn’t yet taken the industry by storm. But innovation is ongoing, and it is likely the challenges will be resolved.

More so, electrically activated substrates hold a lot of promise and could be very useful. Think about an electrical stimulus activating motion in a substrate, for example. Or other types of activation include photovoltaic textiles that may be useful in garments, window blinds or roofing substrates. Such technologies also could be used to create foldable or rollable display screens that would eliminate the need for a separate projector. This sort of technology is not something that could be produced tomorrow – a lot of work and investigation would need to go into how exactly it would work – but materials are available that are appropriate for the job, and there is enough value there that the research is worthwhile.

Textiles also can be conductors. There is one naturally conductive polymer, a polyaniline, that has limited conductivity. But the fact that it exists suggests that there could be development work done to create a more conductive fiber that is more valuable than the currently available polyaniline.

Conductive fibers also can be created using conductive additives such as carbon nanotubes, or by using vapor deposition technologies.

Carbon nanotubes may be used to produce a yarn that is more conductive, but what’s most interesting is that single wall carbon nanotubes are not just conductive, they are super conductors. If these microscopic carbon nanotubes could be embedded in a matrix of polyester, for example, and it was possible to make something with practical length, these new materials could offer a lot of value as super conductors.

It is possible to deposit metal on polymers — for example, silver deposition on nylon — but those fibers get very expensive because of the amount of silver that is involved. However, silver cannot be deposited on polyester using the same process used to deposit silver on nylon. So, imagine a bicomponent fiber with just a sliver of nylon running throughout. Silver could be deposited only on the nylon to create a fiber that offers 100 percent of the conductivity for a fraction of the cost.

Further for the electrical applications, polyvinylidene fluoride is melt extrudable so it can be made into fibers. And when stretched and drawn during production in a properly oriented electrical field, the result is a fiber that is piezoelectric. There must be value in a piezoelectric fiber for use in sensors, actuators or synthetic muscles as just a few examples. This is an untapped, valuable opportunity in the fiber arena waiting for someone to find a solution.

Solvent-Spun Protein Fibers

Moving into another territory with regards to fantasy future fibers, are solvent-spun protein fibers. The horizon in this category is almost limitless. The goal is to use proteins and solvent spin them — ideally using water as the solvent to ensure an environmentally safe process — to make something similar to a synthetic spider silk that has all the properties you could ever want in a fiber — lightweight, strong and with stretch.

There is lots of research in this area and things are getting closer to commercialization every day. Once a solution is found to produce a commercially useable protein fiber, spider silk is just the beginning because there is an entirely new landscape of chemistries to work with that offer an enormous range of new properties. Not just improved properties, but different properties. The field is ripe for picking if the fundamental technology can be mastered. A Wallace Carothers moment in protein fibers is needed, and once that happens, a whole new world will open up that could completely change the fiber landscape in a way not seen in the past 20 to 30 years.

The Third Dimension

Almost maxing out the future “guess-o-meter” are 3D fibers. Innovation first mastered one dimension — how long a fiber is — and that was the only variable. Then research made it possible to control variation in the second dimension to produce bicomponent fibers and non-circular cross sections. But examining the third dimension in fibers may bring lots of value. For example, perhaps it’s possible to change the way a fiber is shaped or its composition along the length — so there is one cross section here and a different cross section further along; or you have one material here and then another material or different combination of materials further along the length. Maybe in 20 or 30 years the industry will be closer to producing such fibers.

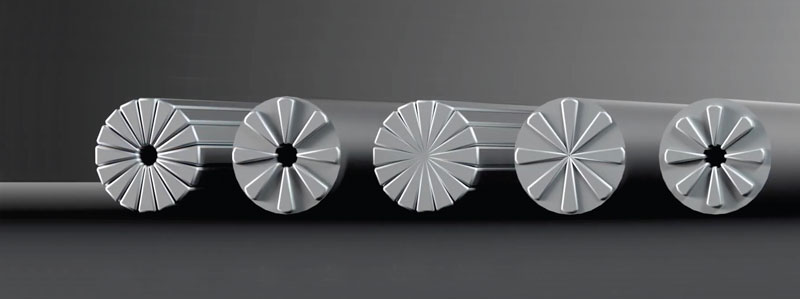

One possible application is in synthetic goose down. Goose down, which has little barbules along the length (See Figure 2), is one of the most expensive fiber products there is. When a goose down batting is compressed, the barbules catch on perpendicular fibers and the fiber bends instead of pushing past. When pressure is released, the down expands back and insulative properties are maintained. A synthetic goose down would be a valuable product, but the technology first has to exist to change the shape of the fiber along the length.

This is just one view of where the future may lie in fibers if the “guess-o-meter” is correct. It might work out that way, or it might not, but past development suggests future direction.

Editor’s Note: Jeff Dugan is the co-founder of Fiber Innovation Technology and he served as vice president of research up until his recent retirement. He still helps people with new fiber projects as a consultant on an occasional basis. During his 39-year career, Dugan authored numerous papers and is named on almost 50 patents. He also presented the first and only TED Talk on the subject of fibers. This article is based on content from Dugan’s presentation, “Future Fibers,” given at the last Synthetic Yarn and Fabric Association (SYFA) conference.

January/February 2023