As advanced technologies continue to evolve from ancient textile methodologies, a broader assortment of opportunities unfolds.

By Jim Kaufmann, Technical Editor

Anyone making a cursory inquiry into the intriguing world of 3D textiles will find that the sector embraces a rather nebulous term leading to an untold number of different routes and a wide array of opportunities. A quick Google search of 3D fabrics, for example, results in somewhere around 325 million hits, which include 3D versions of everything from traditional wovens and knits to nonwovens and non-traditional prints, not to mention an exponentially diverse list of applications, some obvious and others not so much so. An immediate thought surrounding this growing interest is that engineers are finally becoming significantly more comfortable with and accepting of 3D textiles in dynamic performance-based applications. At the same time, product designers continue to become even more adept at creating fabrics or maybe more appropriately fibrous materials, which exhibit these specific technical, visual and/or tactile requirements.

Versatility and clearly defined performance attributes continue to be the prime drivers for interest in 3D textiles. Given that virtually all textile manufacturing technologies can be adapted or modified in some way to create 3D textiles, the breadth of applications is truly almost endless.

3D Weaving, 3D Braiding

3D weaving and 3D braiding continue to see interest and find applications mostly in the composites field, where the emphasis remains on replacing steel in order to achieve weight reduction. According to Dr. Keith Sharp, new product development manager for 3D Weaving at Portland, Maine-based Tex Tech Industries: “3D wovens in composites are perfect for replacing steel. You can weave billets or near net-shape preforms that can be molded into exacting shapes with intricate designs, which saves not only weight, but labor in manufacturing and potentially increases long term reliability as well. There are many applications now, but the LEAP jet engine fan blades that Albany International is 3D weaving are probably the biggest example of this.”

The ability to control fiber placement and tailor yarn paths in order to achieve specific performance profiles is also reflected in the LEAP engine module. According to Albany International’s website, LEAP offers the following benefits:

- “Composite fan module (comprised of blades, platforms, spacers and fan case) is 300 pounds lighter compared to equivalent metallic components per engine;

- Can achieve composite blade geometries that are challenging to produce with titanium;

- Higher impact resistance and lower weight than laminated composite alternatives.”

Interest in 3D woven composites is driving new equipment innovations as machinery manufacturers are becoming more active in the 3D sector. Historically, 3D weaving machines either were highly modified versions of traditional 2D weaving machines, or were custom purpose-built one-offs with specific product concepts in mind. Over the past few years, Switzerland-based Stäubli Group, known for its jacquard warp shed control systems, introduced its technical fabric weaving system — a heavy-duty weaving machine derived with a modular design that when mated to its jacquards or Unival warp shedding control systems, provides incredible flexibility of product design along with the manufacturing capability to produce it.

Not to be outdone, Germany-based Lindauer Dornier — widely known for producing weaving machines for technical, industrial and performance fabrics — recently introduced a collection of products targeted directly at the composites industry. Its Composites Systems now include a machine explicitly designed for weaving 3D preforms. The suite also includes a spread tow unidirectional tape line and machines specifically for weaving rovings and spread tow tapes.

3D Knitting

Recent articles found on websites Gizmodo.com and ZDnet.com make for excellent examples of just how impactful 3D textiles have become. The first article on Gizmodo by Julian Goldman proclaims, “The Future is Knit: Why the Ancient Art of Knitting is High-Tech Again.” The second article on ZDnet by Greg Nichols touts, “The High Tech Science Behind 3D Knitting (yes knitting!).” Both articles focus on the advent of 3D or shaped weft knitting and the control of dimensionality found in knit structures, but not inherent to wovens, along with improvements made in the user interface leading to more effective and efficient knit product designs. 3D knitting offers not only product design aspects — you program the machine, load the yarn and out comes a full garment — it also creates the potential for incorporating wearable electronics into fully fashioned knit products, some of which have already made it to market. Cambridge, Mass.-based Advanced Functional Fabrics of America (AFFOA), a non-profit institute headquartered near the Massachusetts Institute of Technology (MIT) was established through federal funding to advance the use of textile technologies into integrated and networked devices and systems. As part of this effort, AFFOA is focusing on the effectiveness of 3D knitting to create complex shapes. Yoel Fink, AFFOA’s CEO and a professor of material sciences and electrical engineering at MIT, was quoted in Goldman’s article stating: “You’re no longer going to pay for the shirt. You’re going to pay for what that shirt does for you. You pay for the service and you get the fabric.” Certainly a different way of looking at textiles of the future.

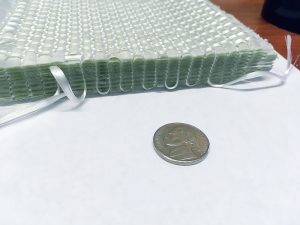

Not to be outdone by its weft knitting cousin, 3D warp knit spacer fabric manufacturers including Hauppauge, N.Y.-based Gehring Textiles Corp. and Apex Mills, Inwood, N.Y., continue to advance the technology’s versatility in new and exciting ways for applications ranging from fashion to seating and bedding, along with other areas where conformability, filling voids, increasing air flow and additional engineering parameters remain desirable.

3D Nonwovens And Additive Manufacturing — 3D Printing

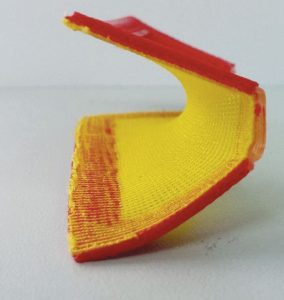

In the grand scheme of things, at least from a textile perspective, it can be argued that 3D printing — which continues to gain interest and attention across many areas — is essentially a more precise version of spunbond nonwovens where polymer is extruded onto a collecting belt or platform where it bonds together, creating a defined structure. The only real difference is that spunbonds typically have a random orientation and bonding pattern, while 3D prints are extruded in precise layers at specific locations. But regardless of whether you believe 3D printing is an extension of textile manufacturing methodologies or not, it has certainly become the it technology and a media darling of recent years.

Originally viewed by many as a way of creating incredibly intricate shapes and novel gizmos, 3D printing now is prophesied as a solution for just about every manufacturing opportunity or shortcoming. The perception, or maybe significance, circling around 3D printing is that it literally seems to imply that if you can conceive it, 3D printing can make it. 3D printing initially found acceptance in rapid prototyping where detailed and exacting one off pieces could be produced, concepts could be explored and theories could be evaluated. As the technology has progressed and generated more interest, new and advanced polymer systems have been developed that include variations for printing “metals,” adding fibrous media as reinforcements and improving the layer to layer integrity of the 3D-printed structure. In conjunction with advancements in the media or inputs used, the size, scope, complexity and consistency of 3D printers also have improved greatly. Over the last several years, 3D printers have grown from primarily being desktop models able to produce at most a cubic foot sized piece — still a core competency — to metal 3D printers as big as a bus with the potential for even larger versions not very far off.

3D printing now is seen as a valid manufacturing technology, particularly where mass customization is preferred or for products that are overly complex, limiting or restricting their process ability via traditional manufacturing methodologies. The advantages continue to be product design possibilities aligned with simplifying the overall manufacturing of complex parts, reducing production time and reducing labor content. This combined with the relatively small footprint needed and increasing reliability of the inputs and resultant products produced present vast opportunities for generating replacement parts in-house instead of dealing with OEM’s and parts suppliers, especially on difficult to reach areas, even for overnight delivery services, like ocean-going ships or even future space travelers.

As the technology continues to advance and scale into more cost-effective, larger-scale productions, potential applications will only continue to grow exponentially. Unfortunately, there’s not enough room here to discuss those applications because there’s an even more intriguing new category on the horizon.

4D Textiles?

While researching for this article, a longtime friend Dr. Chris Pastore, professor of Transdisciplinary Studies at Jefferson University and Fulbright Specialist, asked, “Why aren’t you including 4D textiles in this update?” Researchers at places like MIT, Harvard, Aachen University and Jefferson University, among others, are exploring the possibility of combining textiles and other programmable materials with 3D printing in astounding ways. The term 4D printing is said to be coined several years ago by Skyler Tibbits, director of the Self-Assembly Lab at MIT and a Jefferson University alumni, by incorporating the dimension of time to that of length, width and depth for these structures.

As Dr. Pastore explained: “Wouldn’t it be interesting to combine the flexibility and elasticity of textile materials with the rigid polymer structures of 3D printing to create systems that when you add heat or some other actuator to transform them, they change from two-dimensional structures into complex three-dimensional structures? Or maybe if you were to incorporate shape memory polymers in the 3D print structure, then it’s possible that with activation the object can result in a totally different configuration. Think of the possibility of taking flat textile material then 3D printing a grid over it which can then be activated later. At a later time, you apply an actuator to the flat configuration and it self deploys into a tent. If you think about it, the potential for 4D textiles is tremendous!”

Yes, this concept might cause one to think a bit too much, but several interesting video examples can be found on YouTube that show flat 3D printed structures changing into a different shape. The most famous of these videos shows a seemingly straight line of polymer magically transforming into the initials MIT.

While 4D textiles are still in their relative infancy, they offer yet further evidence that 3D textiles indeed represent a vast opportunity to those with a bit of imagination and some knowledge of the ancient, yet continually advancing technology known as textiles.

September/October 2018