No Shortage Of Solutions

Textile industry looks to suppliers for chemistry that simplifies processes, improves quality

and adds value. What trends do leading suppliers to the industry see on the horizon in

textile chemistry Customers are looking for better removal of waxes and oils, and to improve the

rewetting of the fabric so that wetters and other dyeing auxiliaries are kept to a minimum or

eliminated altogether, stated Scott Jacobs, marketing communications manager,Cognis Textile

Technology, The Netherlands. The trend for volatile organic compound (VOC), and HAP-free

chemistries is continuing we observe a new push for reduction of alkyl phenol ethoxylates in many

areas of the country. Best known for the manufacturing of flame-retardant (FR) chemicals for

the textile and paper industry, Apex Chemical Corp., Spartanburg, S.C., is also looking to the

future. Jeffrey Chamberlain, technical sales manager, said, Today, a large portion of our business

now rests with auxiliary type products such as ultraviolet (UV) absorbers, fluorochemicals, stain

blockers and dye assistants such as levelers, deaerators and dispersants.

Flame test is performed on a 100-percent cotton sample treated with Apex Chemical’s

Flameproof 1725 FR coating. Because we are conventionally a flame retardant manufacturer, we

can look at our market driven somewhat in this order: regulation; innovation; and customer

expectation. We have recently developed a sublimation-fast UV absorber (Uvapex CFW) for

polyester, which contains a unique dispersion package that inhibits spotting on jet-dyed polyester

while offering great lightfastness. The product allows the user to run many more lots of goods

through a jet without cleaning, as our product prevents spotting which commonly occurs due to

build-up of trimer in the jets. Flame RetardantsIf it were not for regulation, there would be

virtually no need for flame retardants, said Chamberlain. We have developed solutions for pending

regulations relating to the manufacturers of mattress ticking and furniture upholstery.We have also

seen an increased need for flame-retardant back coatings, which offer to the consumer a soft hand.

Too often it is felt that certain desirable fabric properties must be compromised in order to meet

flame retardant regulations often this is not true.On other areas of development, Chamberlain

added, There seem to be many innovations introduced using wool. Although wool is an inherently

flame-retardant product, there are certain applications where FR treatment is required. For that we

have developed Apex Flameproof 1694, which rivals the acclaimed Zirpro process in performance but

surpasses it in ease of application.Mike Zavaglia, vice president, Amitech Inc., Oxford, N.J.,

said, We see excellent growth for the domestic textile industry for flame retardants. In the last

few years, we have come out with over two dozen brand new FRs, plus we carry most of the me-too

products. One wrinkle we have focused on is making halogen-free exhaustible FRs for almost every

fiber type. We now have exhaustible products in our line for polyester, nylon, acrylic, wool and

other synthetics. Among the benefits of exhausting over padding [are] softer handle, less color

change from finishing on a frame, better wash durability, better uniformity of the application of

the flame retardant and, in the case of the polyester, the FR actually has increased dye yield

slightly.Our intumescent line is another hot area. We are working with customers in so many

different areas: knits, wovens and nonwovens. The new mattress flame-resistance regulations pending

in California are giving us many opportunities to meet the new requirements with intumescents. Our

intumescent products, we call Pyromescents, can be coated, sprayed or padded on. They can be made

durable to washing, and our entire line has very low smoking properties when the flame is

applied.Pyrozyl 6P is our exhaustible, durable FR we sell mostly into the airline blanket and

automotive industries, said Zavaglia. Improving PerformanceBayer Corp. has a lot of new

protective finishes for textiles and carpets under our BayProtect® hang tag, said Brad Potter,

sales and marketing manager, Technical Textiles. Specific products include Baygard® EDW, which is

an oil/water durability extender based on polyurethane chemistry. Also, along the same lines, is

our line of Baypret® polyurethane finishes for improved abrasion resistance and hand modification.

A recent improvement in our fluoropolymer line of Baygard water repellents is offering new

opportunities in traditional apparel finishing that was not present before.Within the dye

auxiliaries category, Bayer has developed Tanasperse OLG, a unique in-bath trimer reducing

agent.OMNOVA Solutions, Performance Chemicals, Fairlawn, Ohio, recently announced the formation of

RohmNova, a joint venture of OMNOVA and Rohm and Haas Co., Philadelphia. According to OMNOVA, the

joint venture will market, sell and service latex binders, synthetic pigments, and specialty

chemical additives for coating applications in the global paper and paperboard industry. The

parties had been operating successfully as a strategic alliance for more than a year. Products

introduced in late 2001 to the floor care, carpet, and specialties markets, including applications

utilizing the companys proprietary PolyFox fluorochemical technology, are also gaining market

acceptance.Endurion, OMNOVAs high-performance, coated, woven fabric brand, recently was introduced

for upholstery applications in heavy-traffic environments in the hospitality and healthcare

markets.NOVEON Textile Chemicals Inc., Charlotte, reports from a finishing perspective that recent

trends call for apparel manufacturers to produce garments that provide the wearer a new level of

comfort, durability and functionality. Mark Carlough, product manager, textile chemicals, said,

Several products recently introduced to the market to assist textile manufacturers to achieve these

goals are Permax® 200, a first-generation of patent-pending polymers that can be engineered to give

controllable moisture-vapor transport properties in breathable fabrics for sportswear, protective

apparel and other technical fabric substrates. “Fabritone® LT-M8, a new silicone softener, provides

a softer, silkier hand to apparel substrates than previous product offerings. Freecat® brF is a new

catalyst developed for improved efficiencies in Durable Press Resin fixation by utilizing either

lower curing temperatures or greater operating speeds. Unidyne® TG-532, an aqueous fluoropolymer

emulsion originally developed for the nonwoven industry, provides excellent water- and

oil-repellency properties to apparel fabrics with a high level of durability to abrasion and

home-laundering conditions. In addition, the product is free of isocyanate compounds.Carlough

added, Noveon continues to develop new products for the domestic fabric and upholstery markets,

such as print binders and back coatings that enhance end-use properties such as colorfastness,

fabric softness, flexibility and flame retardancy.Cognis Jacobs said, Fabric performance is where

we see the industry moving. There are more and more requirements to improve the hand, moisture

management and durability of soil and water repellency. Cognis has recently introduced a line of

Repellan® durable water and oil repellents to the U.S. market and is in the process of completing

testing of a new line of products called Skin-Tex. These new products are designed to bring the

performance of our cosmetic-base chemistry together with textiles. They would include odor control,

fragrance and other skin nutrients. In addition, we currently have a global agreement with Microban

to provide antimicrobial finishes to the textile industry. Adding ValueRobert Casciani, Ph.D.,

market development manager, Sanitized® antimicrobial products, Clariant Corp., Charlotte, points to

a growing trend of adding value with antimicrobials. The Sanitized brand has offered solutions in

extruded products as well as finishes. Sanitized has been an active brand for over 70 years, and

globally since 1952. Casciani added, The T96-21 product is a versatile antimicrobial finish for

many fabrics and end-uses. On polyester and nylon fabrics it can be applied during dyeing, and can

be applied to polyester, nylon and cotton during frame finishing we need a pH of 5 for the product

to be substantive and provide durable protection.Casciani said, With a growing trend of consumer

awareness regarding chemical finishes on apparel fabrics, the sister product to T96-21 in Europe,

T96-20, has been approved by Oeko-Tex, Switzerland, which certifies products as consumer-friendly.

This is the only antimicrobial product registered under the current Oeko-Tex standard. The trend is

strong in Europe and South America, and we see it strengthening in the United States.As Betty

Tilley, product manager for dyeing and finishing, Apollo Chemical Corp., Burlington, N.C., noted,

Trends that we see are in value-added performance chemicals. Our customers want to separate

themselves from their competitors. Performance is critical, but so is pricing. There are several

segments of the textile industry doing very well, like denim, flat wovens, sheeting these companies

are looking for good products at a very competitive price.Tilley continued, Apollo Chemical Corp.

introduced new patent-pending technology in the area of moisture modifiers. AQUATEK UNO is a

hydrophilic nylon polymer which imparts hydrophilicity to nylon 6 and nylon 6,6 fabrics. When

applied by exhaust to nylon fabric, the product provides absorbency, vertical wicking and moisture

transport to the nylon fabric. With an application of AQUATEK UNO, nylon fabrics have a quicker

evaporation rate than typical nylon fabric. Application by exhaust ensures excellent durability to

home launderings. Application amount varies by weight of fabric and desire to have a durable

finish.Apollo also distributes BioShield AM500, an antimicrobial from BioShield Technologies,

Norcross, Ga. This patented technology inhibits growth of both gram-positive and gram-negative

bacteria, and also controls mold and mildew formation, which often creates odors and discoloration

on fabrics.

trAPTEK’s carbon finishing technique imparts UV protection, as well as odor and moisture

control, to a variety of textile products.Gregory Haggquist, director of technology, trAPTEK LLC,

explained the startup company located in Longmont, Colo., and Bedford Hills, N.Y., is introducing a

durable finishing technique incorporating activated carbon into a wide range of textiles. The

activated carbon adds three major performance features, according to Haggquist: odor management

(trapping odors both from the wearer and the environment); moisture management (increasing the base

fabrics wicking power by up to 100 percent); and UV protection (enhancing the UV protection factor

(UPF) by up to 400 percent) leaving the wearer feeling cool, clean, fresh and natural.

Haggquist continued, The integrity and effectiveness is retained through extensive home laundering,

and potential applications are in the activewear, sock, hunting apparel, carpeting, upholstery,

military, intimatewear, baby products and medical industries. “ATAC” Pretreatment SystemSusan

Cellura, manager, marketing communications, NAFTA, with Ciba Specialty Chemicals, Switzerland,

noted, In pretreatment, we see a trend in simpler recipes at a lower cost constantly trying to make

the pretreatment process more efficient. The demand to reduce cycle times and save water is greater

than ever. Control of iron is becoming a big issue due to customers trying to use a cheaper,

poorer-quality cotton to reduce costs. Preparing cotton under pressure at high temperatures is

becoming more and more common this again is due to mills trying to compensate for a poorer cotton

quality. The use of enzymes to neutralize peroxide is growing rapidly.

Ciba’s Tinofast CEL liquid provides protection against UV radiation when applied to

cellulosics, according to the company. Ciba launched its new ATAC pretreatment system this

year. Cellura reports the system allows mills to significantly reduce the time it takes to prepare

fabric for dyeing and dramatically reduces the amount of water required to effectively prepare the

material. According to the company, it does all this at a price that has saved most plants 10 to 40

percent in their cost to prepare goods. The system includes three products:TINOCLARITE COM is a

combination product and is all that is needed in the bleaching or scouring bath. No additional

lubricant is necessary, and in most machines a defoamer is not required.INVATEX AC is a washing-off

agent that contains special dispersants that allow customers to reduce the number of rinses while

still effectively cleaning up the fabric. It also neutralizes remaining alkali, eliminating the

need to use additional acetic or citric acid. TINOZYM CAT is an enzyme for neutralizing peroxide

that can be carried over into the dyebath without problems eliminating the need for a fresh bath

and saving time and water. Unlike other products in the market, it has an extremely wide pH and

temperature application range this allows you to go straight into any type of dyeing without

worries, Cellura noted.When asked about iron, Cellura said, We are recommending INVATEX AC. This

product is extremely effective at controlling iron. It is effective in a very wide pH range, making

it suitable for addition into any pretreatment step where extra iron control is needed. Dyeing

AuxiliariesThe dyeing industry is constantly seeking improvements in efficiency, energy savings and

product quality, commented Danny Thompson, technical advisor for dyeing auxiliaries, CHT R.

Beitlich Corp., Charlotte. It looks like there are two current trends in the textile industry that

will affect the wet processing of textiles microfibers and stretch fibers particularly in the

apparel area. In general, these fibers create additional challenges for the dyer to achieve level

dyeings with acceptable fastness.Thompson continued, Rewin KMB is used in nylon dyeings as an

in-bath fixing agent. By eliminating the traditional fixation cycle at the end of the dyeing

procedure, this product can save considerable time. The Rewin KMB has leveling properties as well.

And in some cases, it is used as a one-bath leveler and fixative. Because of its special chemistry,

it helps avoid a common problem of residual leveling agent in the yarn or fabric. This residue

carries into the post-treatment fixative bath, where incompatibilities create a precipitation

(usually brown spots) on the dyed substrate. Rewin KMB avoids this precipitation to produce clean,

level, first-quality dyeings.

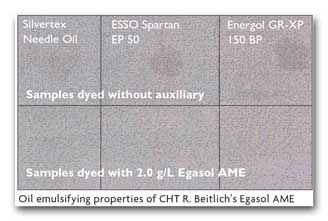

Egasol AME for polyester dyeings has a unique chemistry that allows it to function as

both a leveling agent and an emulsifying agent. This combination of properties can help the dyer

eliminate the traditional pre-scour step on most polyester styles. While still fulfilling its role

as a leveling agent, Egasol AME will emulsify any residual processing oils typically removed during

pre-scour during the dyeing process.For cotton dyeing, CHT R. Beitlich has developed Sarabid LDR,

which can eliminate off-quality dyeings caused by streakiness in piece dyeing and unevenness in

yarn-dyed packages, said Thompson. This product is a special dispersing agent and sequestering

agent that works to prevent agglomeration of reactive dyes. In a non-classical way, the Sarabid LDR

acts as a leveling agent for reactive dyeing of cotton by keeping the dye particles finely

dispersed and protected from water hardness.BASF AG, Germany, has developed the ECOFIT product

range for pretreatment. The ECOFIT products include detergents, wetting agents, extracting agents,

peroxide stabilizers and complexing agents and have been introduced as ecologically and technically

adapted to the meet the requirements of tomorrow.Cyclanon ECO is an ecologically advanced reductive

aftertreatment for use on PES fibers. Cyclanon ECO is supplied in a easy-to-handle liquid form and,

according to the company, the product lowers process costs because there are no pH adjustments

needed anywhere in the process. This, in turn, ensures faster colors in significantly faster

times.Steve Glosson, senior applications chemist, Boehme Filatex Inc., Reidsville, N.C., stated,

Trends that we are responding to with our products are ones that enable savings of cycle/processing

times, energy and water. Our customers are interested in technologies that enable them to get

more performance out of traditionally limited processes. An example would be obtaining better

fastness properties from pigment dyestuffs, enabling darker shades/prints (usually produced with

more expensive dyes with better fastness) to be produced more economically.In the case of the

dyeing of medium to dark shades, our Tabanol RFK-Jet-R, designed for cellulosic dyeing on jets,

enables the dyer to run an abbreviated preparation cycle, along with eliminating several other

chemicals traditionally used in the cycle. The Tabanol RFK-Jet-R eliminates the need for a

defoamer and contains wetting, lubricating, dispersing, and calcium- and magnesium-chelating

properties. Thus, one product takes the place of separate chelate/dispersant, defoamer and

lubricants. This translates into savings of time, energy and chemical inventories.For the

processing of nylon substrates we have developed Durofin SPDX, which is an antioxidant that

protects the fiber from yellowing during dry heat processes during fabric finishing, or, in the

case of intimate apparel, during molding/forming operations. Chemical Supply ChainAt a recent

presentation in Europe titled New Strategies for Catering to Customer Needs, K. Michael Lanham,

commercial director, Xiameter, explained that Xiameter.com is a Web-enabled business introduced by

Midland, Mich.-based Dow Corning that is focused on reducing costs and offering the lowest base

price for standard silicon-based products. Dow invested more than $100 million in back-office over

a five-year period, utilizing the SAP® global platform to create one global Enterprise Resource

Planning (ERP) System. The system offers the ability to view global activities in real-time

ordering, scheduling, production and shipping.Xiameter benchmark product pricing is posted daily on

the site and offers customers choice, low cost and an easy way to do business on-line targeting

customers who buy in large volumes and know what they need in the way of mature silicones.The

company has received a positive reception for Xiameter. According to Lanham, Its a win-win.

Compounders and formulators who know the products they are looking for can get them at lowest cost

with a firm commitment on guaranteed shipping date. Xiameter brings Dow Cornings silicone

technology into the supply chain in an easy, cost-effective way for customers who know what they

want. We still maintain the Dow Corning service level for those who need it as well.DyStar,

Germany, took over the business operations of Color Solutions Inc., Charlotte. As a leading

supplier of color standards to the industry, Color Solutions primary customers are retailers,

producers of brand-name goods and purchasing organizations with global textile interests. Color

Solutions establishes customized color standards on the basis of the customers technical,

commercial and ecological requirements. The company will operate independently under the name Color

Solutions Inc. John Darsey, former co-owner, responsible for global sales, stated, Through its

worldwide presences, DyStar can support the implementation of color standards in textile

mills. Better ChemistryThe textile industry continues to look to suppliers for chemistry that

simplifies processes, improves quality and adds value that differentiates products. There is no

lack of activity in fact, the added-value proposition seems clearly in focus for suppliers. Strong

emphasis on process optimization and quality is a point of consensus, and new products are

appearing on the horizon to assist dyers, printers and finishers to move well beyond commodity

products.

September 2002