TW Special Report

Italy’s Lombardy region is well known for its lakes, mountains, cities, and the typical northern Italian kitchen. It’s also home to many important textile industry companies. Halfway between the idyllic Lago Maggiore and Milan one of them is located: the textile printing specialist “Stamperia Olonia”.

Founded in 1969, now part of the Liberty Group, the company immediately established itself as a leading contract manufacturer of printed natural fabrics for home and apparel. Stamperia Olonia prints on all natural textile fibers up to 320 centimeters wide, digitally and traditionally, using pigment and reactive dyes.

“Thanks to a complete production cycle we can follow the customer from the first bleaching phases to the final quality control. All while we maintain exclusivity and maximum confidentiality towards our customers,” said Fabio Pirino, Finishing department manager of Olonia.

Offering high quality standards at low costs, both on large commissions and smaller production runs, is the company’s mission. Working for the biggest names is for Stamperia Olonia the confirmation of its own expectations and the drive towards continuous growth.

“We are not just a textile print shop! We are an industry that has made research and innovation its philosophy. A partner that combines experience, innovation, and high technology to achieve the highest quality with low costs,” Fabio said.

Over the years, thanks to a policy that is always focused on the future, there has been continuous investment in improving work technology, environmental protection, and safety.

Task Definition

One of these investments was the new software mLog enhanced by Germany-based Mahlo. Olonia produces its goods on many lines with multiple integrated Mahlo systems.

On the newer tenter line an Orthomax RFMB was installed at the inlet. The fusion of pin wheel and roller straightening removes the distortions at the beginning of the line and can also take care of wavy or s-shaped distortions.

The drying/fixing process of the tenter is controlled by an Optipac VMC, the textile process control system from Mahlo. It controls the dwell time, exhaust air moisture and residual moisture during the drying process. Also, the web width is monitored and linked to an alarm, if out of tolerance.

At the tenter outlet, a distortion detection Orthopac FMC monitors the residual distortion.

The challenge was, to keep track of the various Mahlo devices in the tenter line and provide reports for the subsequent processing in a useful manner. This would make the follow-up steps much more efficient.

Solution

As solution, Mahlo suggested the — at that time — brand-new data analysis and management tool mLog enhanced.

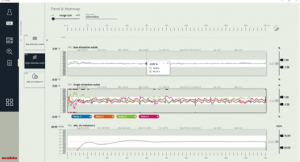

The mLog software is a desktop application for data logging and interactive analysis of historical data for Mahlo equipment. All Mahlo devices of the line could be connected and monitored. With the continuous recording, logs from any desired period could be individually created by Olonia itself.

Initially mLog was part of a project where a new machine had to be adapted to Olonia’s management system. But it turned out to be more effective to fetch data of all Mahlo systems in the new stenter line with mLog and feed the data to a host computer via an interface with OPC UA.

Success

mLog enhanced is running now on the Olonia lines since January 2020 Olonia’s project team collaborated intensively with the Mahlo development department. So, a lot of its useful ideas and requests, coming directly from a working production line, have been implemented by Mahlo as software features. Still, they are constantly improving their processes as Mahlo provides new functions and updates on the software.

Since the installation, the printing specialist has seen some significant improvements, as Fabio explains, “Through the control of the system, a standardization of the process was achieved, especially regarding digital preparation. Additionally — particularly in terms of energy — the costs could be optimized.”

With the new data management, Olonia could streamline their processes substantially. When a new badge is fed into the tenter, the operator simply scans a code. That code starts the report in mLog enhanced for the badge automatically.

When the end of the roll is reached, the operator scans a stop code. This stops the mLog recording and saves the report to the database. Thus, with only two scans, the data of the entire batch is available for further processing in Olonia‘s management system.

While saving, a PDF version of the report is automatically stored on the customer‘s server — of course with the correct name, in the correct directory, as set by Olonia. In addition, different report variants are created. On the one hand an internal, very detailed report, and on the other hand a version for the customer, which is shorter and summarizes the important points.

Future

The solution is very sustainable because it allows production to be monitored and energy wastage to be avoided depending on processing. Seeing the success, Olonia plans to optimize its processes even further.

December 7, 2023