O

O

nce again, the push for CBI parity has failed in the U.S. Congress. As a result,

Caribbean Basin countries will have to wait longer for increased access to the U.S. market.

For many U.S. manufacturers and importers, they will have to wait for better access to the

quality manufacturers of the Caribbean. But, for Mexican textile and apparel manufacturers, the

delay is probably a good thing, as Mexico will continue to enjoy a significant advantage over the

Caribbean through NAFTA and will have more time to further solidify its position as the major

competitor for Caribbean Basin countries.

Under NAFTA the Mexican textile and apparel industry has blossomed. Exports to the United

States have skyrocketed in recent years. Also, new investment in Mexico is now at an all-time high,

with investors flocking from the United States and other countries as well.

With such explosive growth, Mexico has much to fear from a successful implementation of NAFTA

parity for the Caribbean. Whereas Caribbean nations now face clothing quotas, Mexico faces few.

Mexican exporters enjoy low or zero-percent U.S. import duties for many products, and CBI faces

normal MFN tariff rates. Additionally, Mexico maintains a growing textile industry in support of

its apparel capacity further enhancing Mexican competitiveness. The Caribbean, in turn, does not

have much of a knitting or weaving industry.

Under the proposed versions of NAFTA parity for the Caribbean, these advantages would go away

as the Caribbean would enjoy NAFTA-style tariff and quota benefits. Further, special provisions of

the proposed NAFTA parity legislation will go a long way to helping certain Central American

countries to develop a more vigorous textile industry in support if their already aggressive

apparel industry.

For American apparel companies, the stakes are high, as many firms see the preferential

provisions of NAFTA with Mexico, coupled with such provisions for the Caribbean, as the only

effective way to compete in today’s world markets. As domestic apparel manufacturing has become

more and more expensive, outward processed (“807”) and full-package production in Mexico and the

Caribbean using U.S. piece goods are some of the only viable manufacturing options left — short of

abandoning manufacturing all together and sourcing everything from the Far East.

The Mexican Apparel Industry

The apparel industry in Mexico represents one of the largest manufacturing sectors in the

Mexican economy. Employing nearly 460,000 workers, Mexican apparel industry employment has more

than doubled since 1993. It is estimated that Mexico’s apparel industry produced nearly $8.5

billion of product in 1998, up from just $3.6 billion in 1993.

There are currently more than 22,000 apparel companies in Mexico, with the average company

employing just about 40 workers and with many companies employing less than 5 workers. So-called

large firms (with more than 500 workers) account for less than 2 percent of all apparel companies

in Mexico.

Because there are so many small manufacturers in Mexico, these companies tend to be easily

buffeted by market trends, as they do not typically have the financial resources to ride out stormy

periods in the Mexican economy.

Although many of the firms operating in Mexico originally acted as Macquiladoras (that is,

they acted as assemblers of U.S. components) they have moved their production more and more into

the full-package arena. It has been easier for these companies to do so as they have received

better training and investment for United States and other apparel importing companies.

As the quality and price of the garments produced in Mexico has improved, the traditional

Macquiladora assembling activity has dropped. In fact, “807” type exports to the United States has

fallen from an equivalent of nearly 93 percent of all Mexican apparel exports in just 1993 to only

about 80 percent in 1998. In 1999, this percentage has fallen even more. At the same time, total

U.S. apparel imports from Mexico has soared from $1.3 billion in 1993 to more than $6.7 billion in

1998. The United States is the largest export market for Mexico by far with more than 90 percent of

all Mexican apparel exports going to the United States in 1997.

For many products, 1999 was the first year for zero duty status under the NAFTA agreement.

Under the “807” duty structure, duty is only paid on the value added in Mexico; thus it made

economic sense to use U.S. cut pieces for apparel assembly in Mexico. Now under NAFTA, however,

U.S. import duties have gone to zero for many key products, thus changing the economics so that it

makes much more sense to produce full-package garments in Mexico and forgo the U.S. cutting step

required under the “807” provisions.

The Mexican Textile Industry

Several large mills dominate Mexico’s

textile industry, but there are a variety of smaller manufacturers that fill specific niches in the

Mexican market. For years, Mexico’s textile industry was largely sheltered from the challenges of

global trade thanks to a high import tariff structure enforced by the Mexican government. As key

supporters of the traditional closed Mexican political system, textile interests were able to all

but close down their domestic market to foreign competitors.

The largest mills are almost exclusively family owned. Although in general these firms are

not of the scale of the largest U.S. mills, they do control significant portions of the Mexican

market. The financial strength of these firms varies and the impact of the relatively recent peso

crash and ensuing currency debacle cannot be understated. Because of the shaky financial status of

many of these firms leading out of the peso disaster, many of these firms looked to partner with

stronger, larger U.S. mills. Many U.S. firms, in turn, looking to better supply U.S. apparel

companies that had moved into Mexico after the signing of NAFTA, welcomed the new

partnerships.

Investment Opportunities

There have been several

well-publicized investments in Mexico. These include new investments/joint ventures of Burlington

Industries, Cone Mills

(See “Success Through Partnership” in this issue.), Guilford Mills, Kosa and DuPont. As of

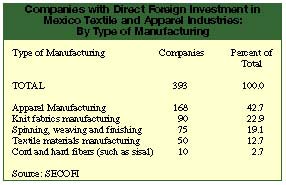

1996, 393 companies were registered with the Mexican government as having direct foreign investment

related to the textile sector. This represents about 3 percent of all firms with foreign capital in

Mexico (about 13,000 firms in total).

Based on their primary manufacturing activity, as reported to the Mexican government, about

43 percent are classified as apparel manufacturers; 23 percent as double-knit fabric manufacturers;

19 percent spin, weave and finish fibers; 13 percent manufacture textile materials and about 3

percent in the hard fiber textile industry.

As for the origin of foreign investment in textile manufacturers, more than 70 percent of

them have U.S. capital; nearly 4 percent have Spanish investment; 3 percent Korean; 2.5 percent

Canadian; and over 20 percent from other countries. More than a quarter of these firms are located

in the Mexico City area. Between 1994 and 1996 (the most recent years reported), more than $340

million of foreign capital was invested in Mexico’s textile sector. This equates to about 2 percent

of all foreign capital invested in Mexico during the same period (about $16.5 billion).

Of the foreign capital invested in Mexico’s textile industry, more than $133 million were

invested in spinning, weaving and finishing operations (39 percent of total textile and apparel

sector); about $89 million were invested in knit fabric manufacturing (26 percent of total); more

than $83 million were invested in apparel manufacturing (about 24 percent of total); and more than

$36 million were invested other textile-related activities (almost 11 percent of total).

A Transitional Mechanism

While

While

the export and production growth of Mexico’s textile and apparel industries has been stunning in

recent years, much of this growth is directly attributable to the duty benefits of the NAFTA

agreement, along with the shorter delivery times afforded to Mexican manufacturers due to the close

geographic proximity to the U.S. market.

However, the benefits of NAFTA may prove to be fleeting at best for U.S. apparel companies

now sourcing product in Mexico, as any CBI parity legislation will force a more even playing field

with the Caribbean and the WTO quota phase-out of the Multifiber Arrangement will make it much

easier for Far Eastern firms to gain entry to the U.S. market. Further, MFN import tariffs have

been cut under the terms of the WTO agreement. All of this not only represents a significant

reality for U.S. companies new to the import sourcing game, but also represents a profound threat

to the long-term prospects of Mexico’s apparel industry. In particular, “807” production will be

under increasing pressure to compete.

Although agreements such as NAFTA and CBI Parity have and will help certain U.S. and

regional firms to be more competitive, these agreements should perhaps be viewed as being

transitional, designed to assist U.S. manufacturers to ease their way offshore. NAFTA in particular

should be viewed as a means to end — not a final solution for America’s textile and clothing

industries. In time, it is unlikely that NAFTA or the CBI legislation will be able to halt an

inevitable climb in imports from the Far East brought about be elimination of MFA quotas and

reduction of import tariffs under the WTO agreement.

Impact Of China

China

China

is lurking once again as a major competitor poised to dominate the U.S. market. Whereas exports

from China and other major suppliers in the Far East had fallen in recent years, this trend has

begun to reverse itself. At the same time, the recent U.S. offer to not resist China’s efforts to

enter the WTO and support of a shortened five-year elimination of MFA quotas, represents not only a

wholesale sellout of the domestic textile and clothing industries by the U.S. government, but a

potentially devastating blow to the Mexican textile and apparel industries and a threat to the

long-term viability of the NAFTA agreement.

In turn, these developments will translate into a significant challenge for the Caribbean

nations — with or without NAFTA parity.

Because of the five-year entry time for China’s quota-free access to the U.S. market (other

suppliers will have to wait for a total of 10 years), domestic manufacturers will be faced with

more competition than ever. Low prices will also be more important than ever. Once China is free

from import quotas, their industry will move quickly to more efficiently utilize the full capacity

of its massive textile and clothing industries.

The recent overcapacity problems that have plagued many sectors of the Chinese textile and

clothing complex will gradually cease to be a problem and exports will rise substantially. Export

gains will be further enhanced by the lower import tariff rates agreed to by the United States in

the WTO agreement. This will all translate into lower prices in the U.S. market.

The Bottom Line

It is possible that as China and

other Far Eastern suppliers make inroads into the U.S. market, many U.S. firms, which have already

invested heavily in Mexico, will be forced, for competitive reasons, to move their investments out

of Mexico in favor of other more competitive regional producers. In turn, the impact of a possible

Free Trade Agreement of the Americas may act as further incentive for U.S. firms to move even

farther and farther South away from Mexico.

The bureaucrats in Washington, Beijing and Geneva have, in some ways, sealed the fate of the

Mexican apparel industry. With China’s inevitable entry into the WTO, the Mexican apparel industry

will be hard pressed to compete in the U.S. market. At the same time, possible NAFTA parity for the

Caribbean will also represent a challenge. As a result, much of Mexico’s economic progress in

recent years may be undermined and substantially disrupted.

After the recent WTO ministerial meeting in Seattle, the question was asked by many: why are

they all sleepless in Seattle? Lost in the public display of anger over the role of the WTO in

world trade and the impact of multilateralism on the environment and traditional ways of life, such

as farming, was the fact that the U.S. textile and clothing industries have been dealt a severe

blow by being traded away in the name of global trade.

It is ironic that Mexico’s textile and apparel industries, which are so closely tied to U.S.

manufacturers, are now also in danger of being undermined by those very forces that fought so hard

to have NAFTA passed in the name of free trade in the first place.

January 2000