TW Special Report

Although productivity of blowroom machinery has increased steadily in the last decades, few innovations have revolutionized the concepts of opening, cleaning and blending of the fiber. Opening of the fiber is still carried out through feed rollers and beaters, whose speed ratio can be as high as 150/1. Higher production has been achieved through higher speed of the beaters and more aggressive carding elements, often affecting the elasticity, natural resistance and length of the fiber.

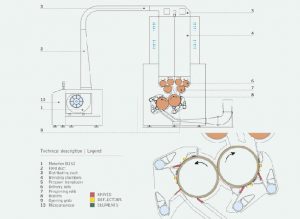

Marzoli has introduced some innovations in its lines to specifically address this drawback. Stress and shortening of the fiber is caused primarily in openers by feed systems that nip the fiber and present it to fast-rotating beaters. Marzoli’s fine opener has a pre-opening roller between feed rollers and beater. The fiber is treated much more gently because the fiber is not nipped and the pre-opening roller accelerates the fiber before delivering it to the fast rotating roller.

Opening performance is guaranteed by two consecutive beaters, surrounded by four carding segments. Each carding segment is followed by a mote knife with deflector: every time the material is opened, trash and dust are discarded. Knives and deflectors are individually settable so that the best fiber selection can always be achieved with every kind of material.

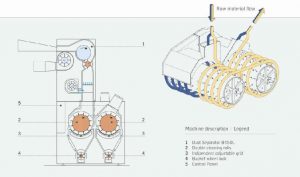

In order to achieve excellent cleaning performances trash should be discarded as much as possible by the coarse trash cleaner: throughout the process, trash is broken into smaller pieces which are increasingly harder to remove. Marzoli coarse trash cleaner has two beaters with independently-settable grids and a large working width. These features entail a lower density of the throughput, a higher number of turns on the grids (8 times) and consequently a better cleaning performance.

Another crucial task of modern blow room machinery is to effectively blend the material. The automatic bale plucker traveling on the bales, with two plucking rollers and the higher number of blending chambers in the line guarantee maximum homogeneity of the tuft blend. Marzoli’s mixer B143L can have 4 or 8 blending chambers. The material within each chamber is fed to an opening roller and the resulting flocks are delivered to a blending channel where suction from the downstream machine effectively blends them.

Modern blow room machinery must minimize the formation of neps which are mainly formed by the air currents created by motor fans. Marzoli in its lines installs cage condensers instead of motor fans, which, not only minimize the formation of neps, but also dedust the material after every opening stage.

August 16, 2018