A Hybrid Market

New developments in nonwovens are stemming more from evolution than from

revolution. New product research and development is the lifeblood of almost every

business. However, there is no simple route to developing new products. With few exceptions, most

new products result from evolution in technology rather than revolutions in technology. Many new

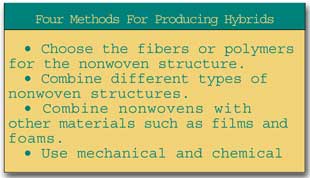

products are developed by combining existing materials or processes to form a new product which is

a hybrid. Hybridizing can then be considered as a process for developing new products. It can be

considered that whole field of nonwoven technology as a hybrid, since nonwoven technology

represents the combining of several basic technologies such as textiles, paper and polymers.

Spunbond/Meltblown (SMS) ProductsKimberly-Clark has been the pioneer in combining

meltblown nonwovens with spunbonds to develop a whole family of new products. The SMS products that

have been developed by using a layer of meltblown polypropylene sandwiched between two layers of

polypropylene spunbond are used for surgical wrap and for limited use in protective clothing and

for automobile protective covers. Another development using combination technologies by

Kimberly-Clark is their Coform system. This system creates a blend of meltblown polypropylene

microfibers and powdered materials which is then formed onto a spunbonded carrier sheet.The

semi-molten meltblown fibers, combined with the pulp and powdered materials, acts as a

chemical-free adhesive system.The combination web formed by this process becomes a dimensionally

stable, absorbent structure, even when it is wet. Thinsulate3Ms Thinsulate is used for apparel

and footwear insulation. This product is made by incorporating a carded web of heavier denier

crimped polyester fibers into a microdenier meltblown polypropylene web. The finer microdenier web

provides the insulation properties and the carded web provides resilience for the composite

structure. Water Blocking TapesThe swelling layer consists of a lightweight nonwoven coated

with a chemically pure cellulose that is aerodynamically applied to become a super absorber.

Super-absorbent fibers in the form of nonwovens produced by dry-laid processes are also used in

this application. The backing layer is a polyester nonwoven such as a spunbond, or a dry-laid

fabric reinforced with a polyester scrim.Many communications cables and fiber-optic cables contain

a paraffin-like, highly viscous filling compound as a water-blocker in the cable core assembly. A

swelling tape is applied to the filled cable core to seal off any cavities under laminated

sheaths.To prevent the petroleum jelly from penetrating the nonwoven and impairing its swelling

properties, polyester film is laid longitudinally over the cable core assembly and to wrap the

swellable nonwoven around it in a second manufacturing step. Printed Circuit BoardsTo create a

circuit board, a series of procedures must be followed. A circuit board is made by producing an

isotopic aramid nonwoven, impregnating the nonwoven with the crosslinking resin system, drying the

prepreg and obtain B stage crosslinkage, laminating it with copper foil in a roller laminator under

clean room conditions, and then hardening the composite material for five hours at 120oC.A major

advantage of this system is that the layers are bonded without using a solvent-containing

adhesive. Battery SeparatorsComposite products have been developed for open systems of

nickel-cadmium secondary cells. These cells are used in airplanes, rail vehicles and emergency

generating sets. The electrolyte carriers used are polypropylene or polyamide nonwovens, combined

with cellophane films or hydrophilic polypropylene membranes. Filtration ProductsCartridge

filters can be formed by meltblowing or spray spinning techniques. Celanese Fiber Co. developed the

Hytrex cartridge filters by using a spray spinning technique to produce a shaped cartridge filter

of varying density. The Hytrex process and trademarks were sold to Osmonics Inc. which now markets

these filter products. The Pall Corporation produces shaped cartridge filters by a modified

meltblowing technique. Automotive ProductsThe application of polyethylene to jute carpet

backed automotive carpeting to aid in its forming was an important development in the 1960s.

Freudenberg Spunweb Co. has successfully introduced their Lutradur spunbonded polyester fabrics for

moldable automotive carpeting.The high strength and ease of molding of the Lutradur permits the

carpeting to have a deep draw configuration without encountering problems with punctures from high

heels or similar hazards.Freudenberg in Germany developed a molded sound-absorbing automotive

engine cover using polyester nonwoven fabric. Freudenbergs pleated polyester nonwovens are now used

for air filtration media for car interiors.DuPont has done extensive work in developing moldable

automotive and tractor seating fabrics that incorporated their Lycra® spandex to facilitate fabric

molding. Molding Of FabricsCutting and sewing have been the traditional methods of joining and

shaping textile fabrics into three-dimensional shapes.The felting of animal fibers into end items,

such as hats, was one of the earliest methods of directly forming and molding fibers into a final

product. Felts are also made in block form and other shapes by felting the wool or other animal

fibers within a shaped form.Until thermoplastic fibers became available, it was not possible to

directly form or shape fibers other than through felting. Garment MoldingGarment molding

presents one of the most challenging areas for development of fabric molding technology. In the

early 1970s, Teijin of Japan developed techniques for molding womens dresses using tubular

double-knit polyester fabrics.With the increasing array of nonwoven fabrics now available, it is

expected that molding and forming will continue to grow for specialty products such as automotive,

filtration and other industrial products.The commercialization of limited use and disposable

garments using molding technology for hospital/medical and clean room applications is also expected

to increase.

August 1999